Controlled cooling equipment for manufacturing expansion-breaking connecting rods by using non-quenched and tempered steel

A technology of expanding connecting rods and non-quenched and tempered steel, applied in heat treatment equipment, manufacturing tools, furnaces, etc., can solve the problems of good cooling control effect, low cost, simple process, etc., and achieve strong cooling control process and high safety The effect of the degree of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

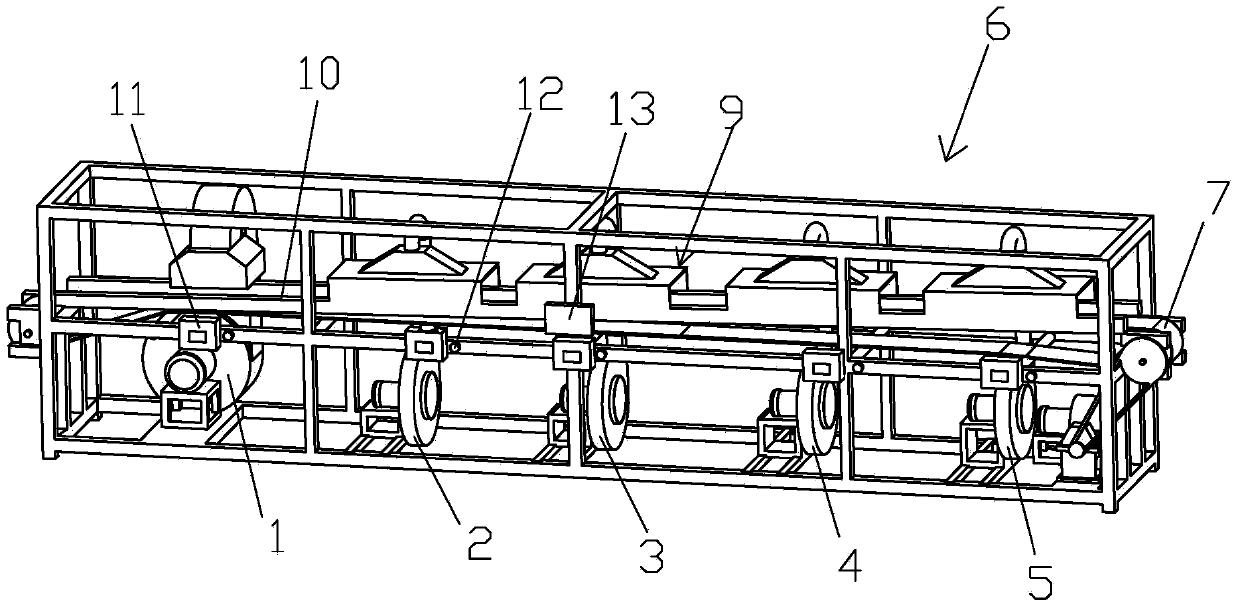

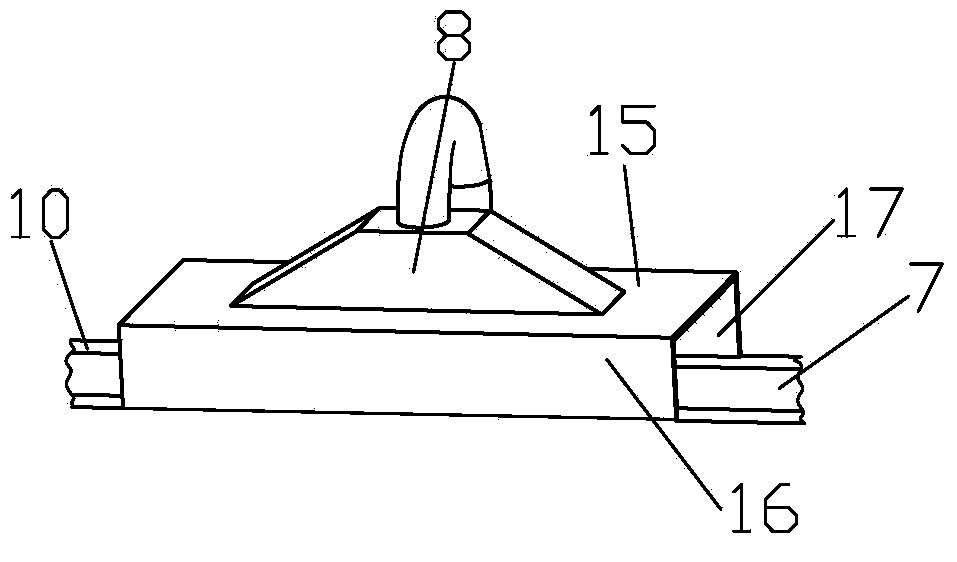

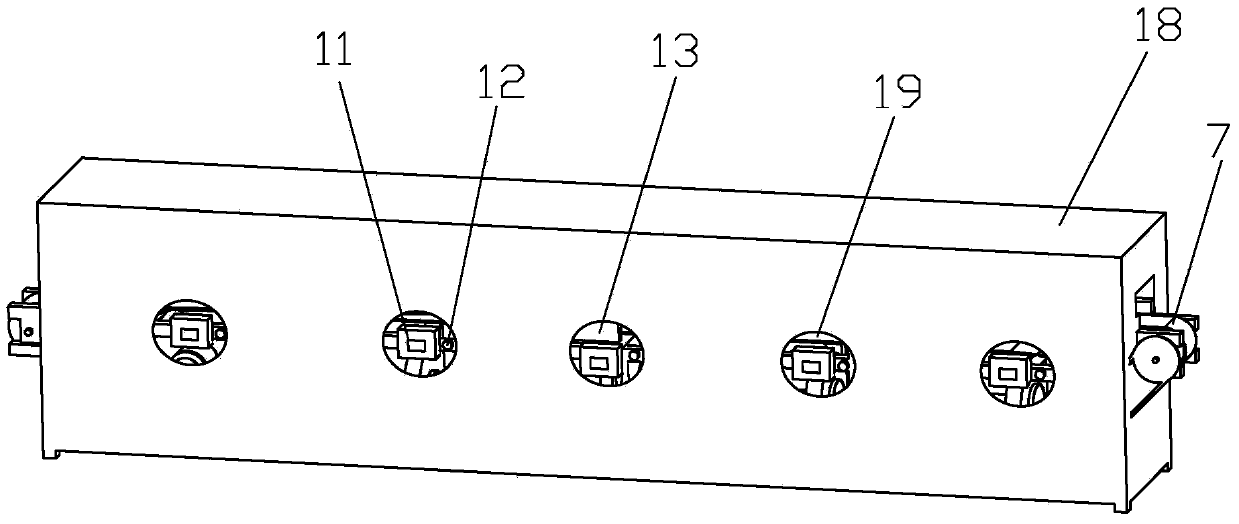

[0023] Embodiment: a kind of controlled cooling equipment that uses non-quenched and tempered steel to make the expansion-broken connecting rod, such as Figure 1~3 Shown, comprise frame 6, be provided with first blower fan 1, the second blower blower 2, the 3rd blower blower 3, the 4th blower blower 4 and the 5th blower blower 5 that are arranged in a line in the stand 6; Also be provided with an endless conveying chain 7, described endless conveying chain 7 is positioned at the air outlet 8 of the first blower fan 1, the second blower fan 2, the third blower blower 3, the fourth blower blower 4 and the fifth blower blower 5 Below; at the blower outlets of the second blower fan 2, the third blower blower 3, the fourth blower blower 4 and the fifth blower blower 5, an isolation cover 9 is arranged; There are steel bars 10, and the steel bars 10 are fixed on both sides of the endless conveyor chain 7, and the isolation cover 9 is fixed on the steel bars 10; the first fan 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com