Preparation method of optical fiber decoration cloth, product and luminous decoration device

A technology of decorative cloth and optical fiber, which is applied in the direction of lighting devices, fixed lighting devices, semiconductor devices of light-emitting elements, etc., and can solve the problems of complex manufacturing process, large limitations, and inability to blend cotton yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

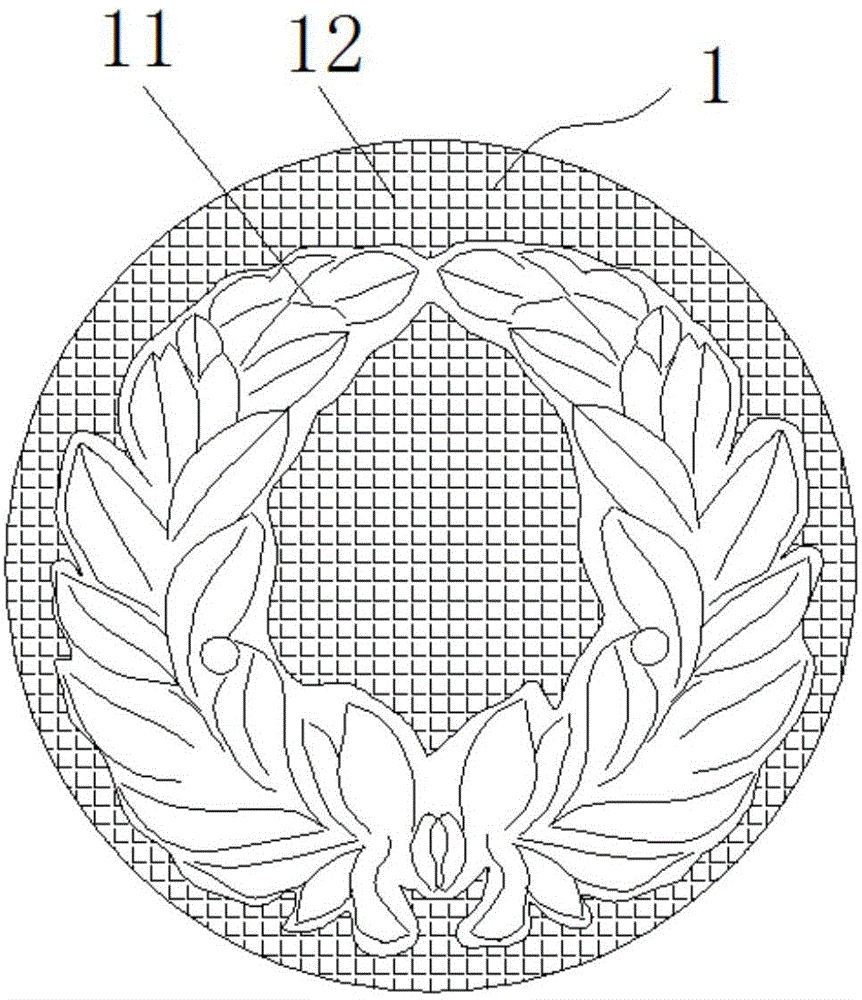

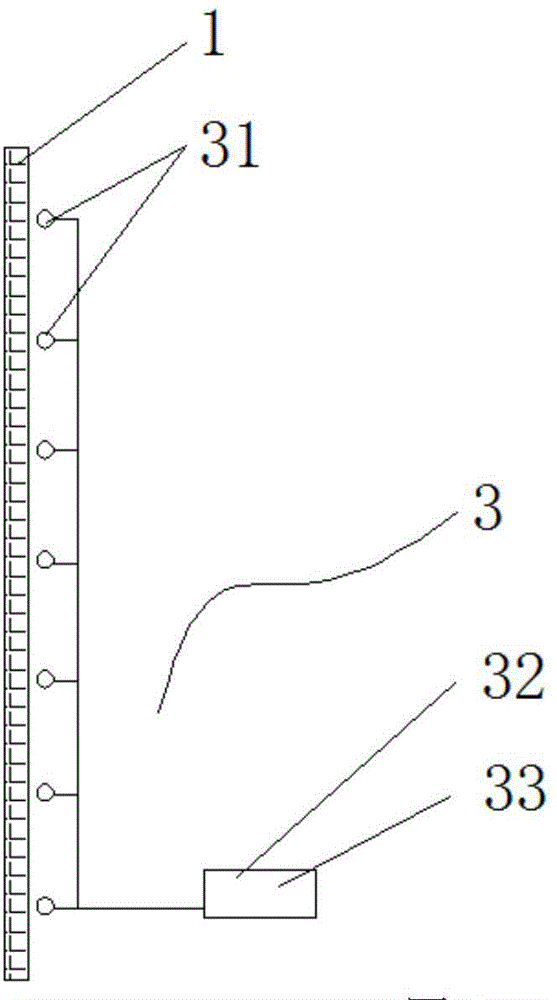

[0027] Example: see Figure 1 to Figure 2 , the preparation method of the optical fiber decorative cloth provided in this embodiment, it comprises the following steps,

[0028] (1) Prepare the core thread: reflective yarn is obtained after the surface of the yarn is coated with reflective material, and multiple strands of reflective yarn are twisted into a reflective core thread; the surface of the yarn is coated with reflective material for color , forming a colored reflective layer on the outer surface of the yarn, and then forming a colored reflective layer on the surface of the core thread;

[0029] (2) Prepare jacquard yarn: prepare transparent or translucent optical fiber, take the core wire described in step (1) as the center, surround and interweave multiple strands of optical fiber on the outer surface of the core wire to form transparent jacquard yarn; The optical fiber is a transparent or translucent plastic fiber or reinforced glass fiber;

[0030] (3) A pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com