Fabricated wood structure embedded steel bar joint and construction method thereof

A wooden structure and assembly technology, applied in the direction of building construction, construction, building materials processing, etc., can solve the problem of limited flexural bearing capacity and rotational stiffness of joints, which can only be used in simply supported or hinged situations, design and construction Incompetent installation and other problems, to achieve the effect of reducing maintenance and repair costs, high practical value and economic value, and good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

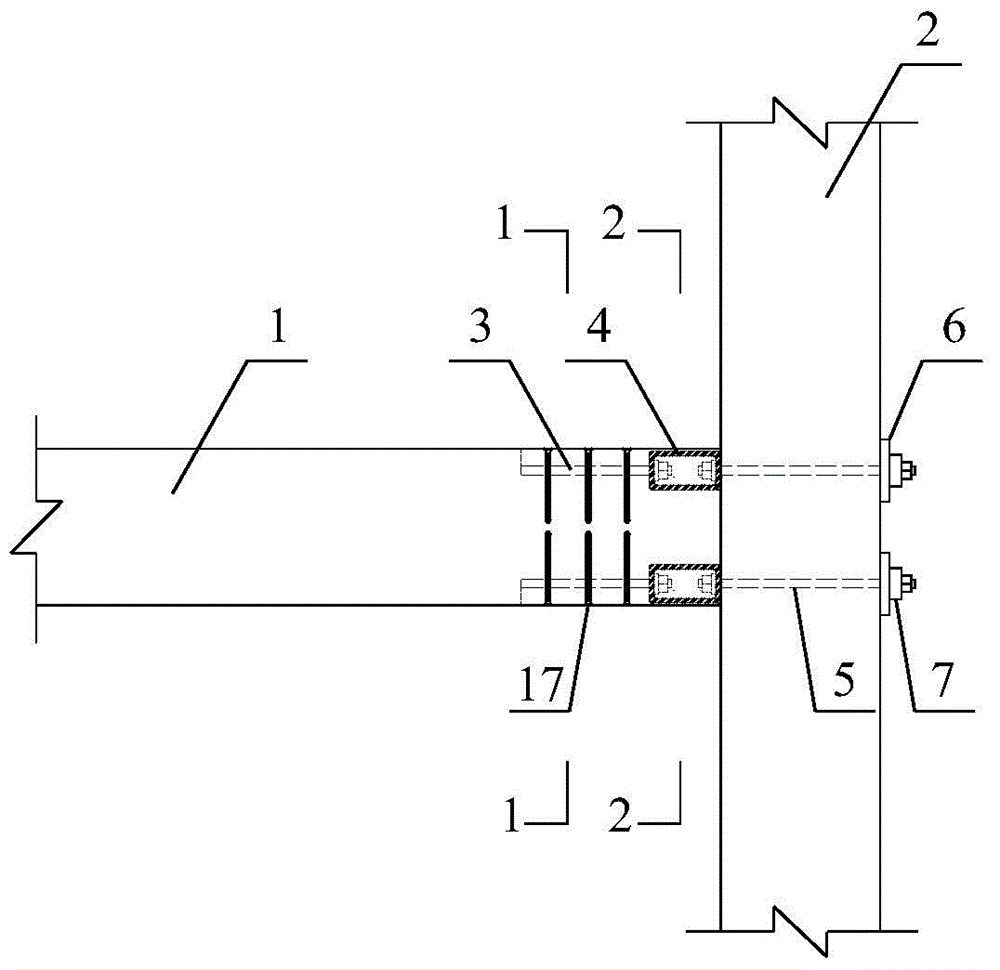

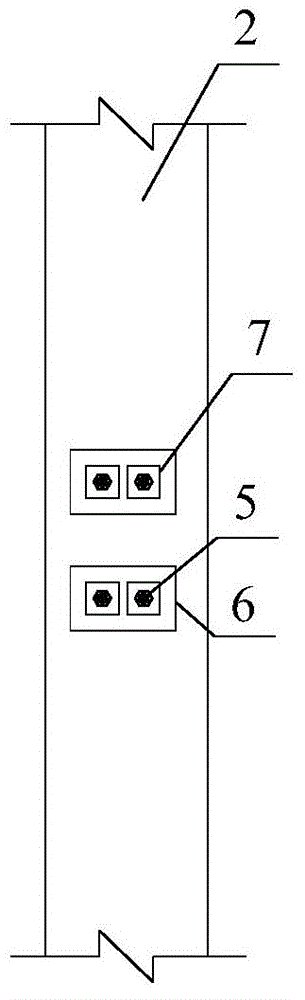

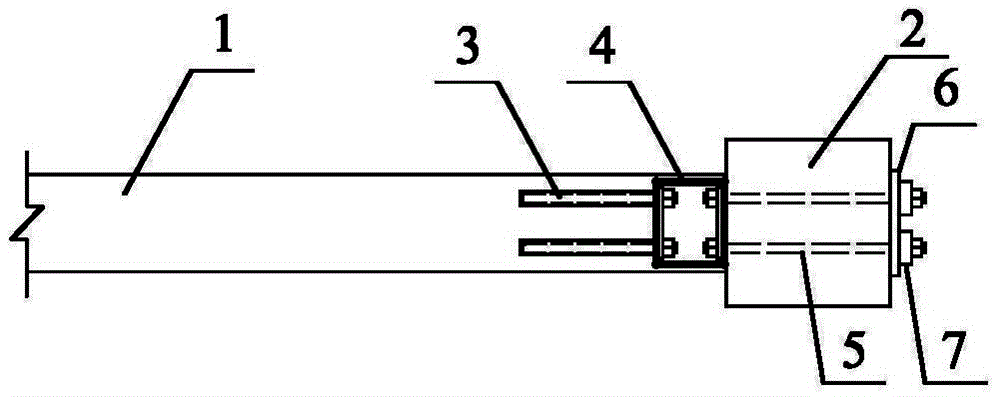

[0047] Such as figure 1 , 2 , 3, 9 and 10, a kind of prefabricated wooden structure planting reinforcement node, including wooden beam 1, wooden column 2, beam end planting reinforcement 3, node connector 4 and node fastener 5, described wooden beam 1 and wooden The columns 2 are connected by the node connector 4, the beam end reinforcement 3 and the node fastener 5, the node connector 4 is fixed on the column body through the node fastener 5, and the node fastener 5 passes through the anchor plate 6 and the spacer 7, The side of the wooden column 2 facing away from the wooden beam 1 is fixed, and the beam end is reinforced with self-tapping screws 17 at the reinforcement site; Figure 6-8 As shown, the beam end planting bar 3 is planted in the pre-drilled or reserved hole 8 at the beam end or in the opened channel 9 through structural glue, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com