Hydraulic joint used for clamping test piece with superfine pipe diameter

A technology of hydraulic joints and test pieces, applied in the field of aerospace science, can solve the problems of increased production cost, low production efficiency, low positioning accuracy, etc., and achieve the effect of saving cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

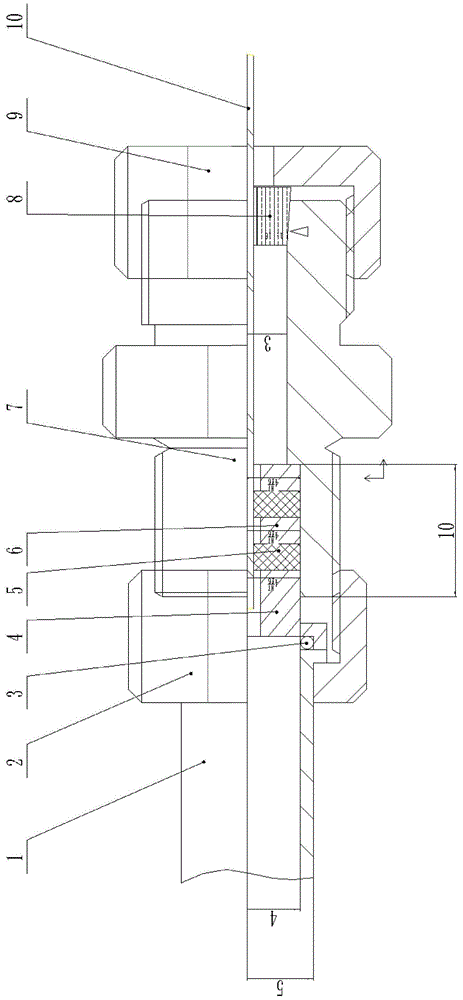

[0019] See figure 1 , the present invention is a hydraulic joint for clamping micro-diameter test pieces, which includes: an improved pipeline pressure inlet joint part, a sealed clamping part, and an improved pipeline pressure outlet joint part, and the positional connection relationship between them is : The improved pipeline pressure inlet joint part is located at the left end of the sealing clamping part, and the two are connected by threads; the improved pipeline pressure outlet joint part is located at the right end of the sealing clamping part, and the two are connected by threads.

[0020] The improved pipe pressure inlet joint part includes two parts: hydraulic pipe 1 and hydraulic pipe nut 2 at the left end, which are socketed; this part is located on the left side of the joint main body 7, and the hydraulic pipe nut 2 can be selected to cooperate with the standard part of the joint main body The nut of the standard part, which can rotate freely relative to the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com