Electric arc furnace and preparation method thereof

An electric arc furnace and furnace bottom technology, applied in the field of steelmaking and smelting, can solve the problems of water tank leakage, increase of production cost, explosion in the furnace, etc., and achieve the effect of improving safety performance and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

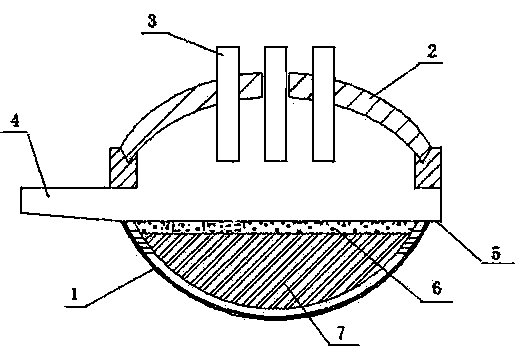

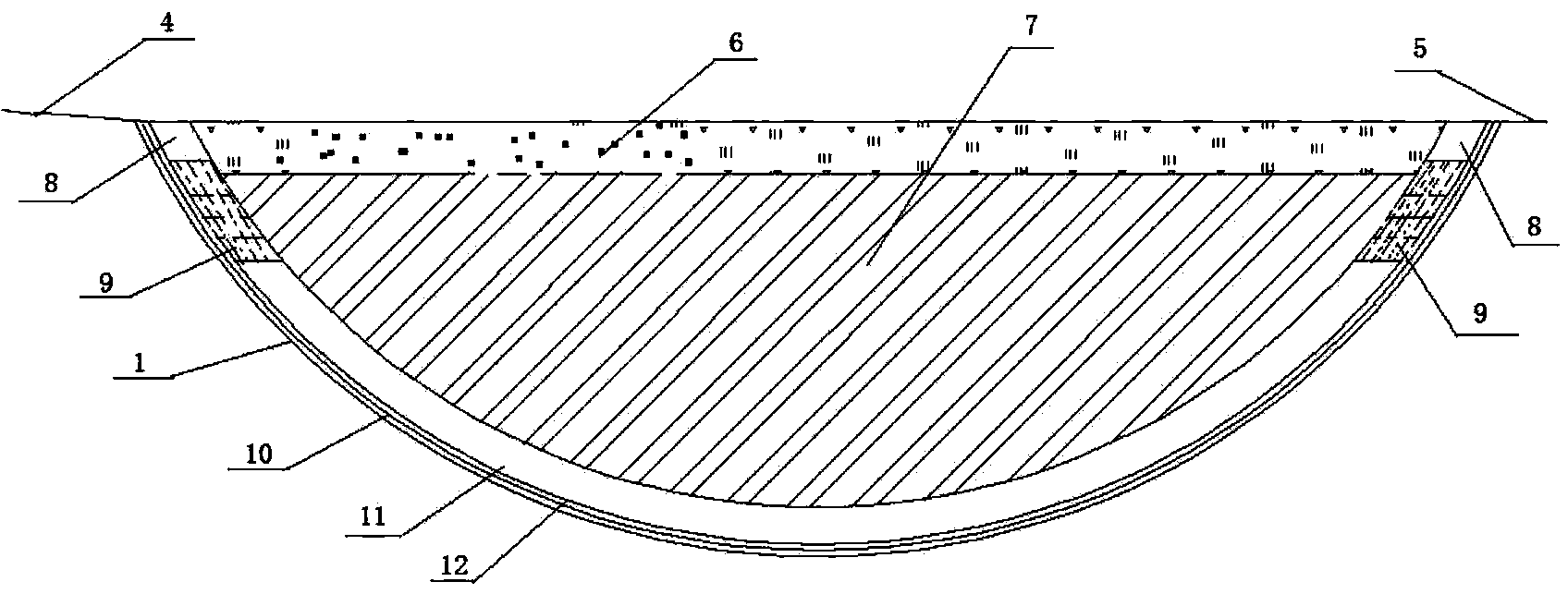

[0022] like figure 1 and figure 2 As shown, a preparation method of an electric arc furnace comprises furnace bottom 1, furnace cover 2, electrode 3, tapping hole 4, furnace door 5, electrode 3 is inserted into the furnace through the hole on furnace cover 2, and furnace cover 2 is covered in On the furnace bottom 1, a tap hole 4 and a furnace door 5 are formed at the joint between the furnace cover 2 and the furnace bottom 1, and a 5mm, 6mm, 7mm, 8mm, 9mm or 10mm thick asbestos board 10, spread the asbestos board 10 to the furnace door 5 and the tapping hole 4, and lay a layer of high-alumina bricks 12 on the surface of the asbestos board 10 at the furnace bottom 1. Sprinkle a layer of magnesia 11 and tamp it tightly, and then sprinkle with brine magnesia in layers with a thickness of ≤80mm to knot the furnace bottom 1, first knot the arc-shaped part of the furnace bottom 1, and then knot the slope of the furnace bottom 1, Beat until the surface turns white and there is a ...

Embodiment 2

[0024] like figure 1 and figure 2 As shown, a preparation method of an electric arc furnace comprises furnace bottom 1, furnace cover 2, electrode 3, tapping hole 4, furnace door 5, electrode 3 is inserted into the furnace through the hole on furnace cover 2, and furnace cover 2 is covered in On the furnace bottom 1, a tap hole 4 and a furnace door 5 are formed at the joint between the furnace cover 2 and the furnace bottom 1, and a 5mm, 6mm, 7mm, 8mm, 9mm or 10mm thick asbestos board 10, spread the asbestos board 10 to the furnace door 5 and the tapping hole 4, and lay a layer of high-alumina bricks 12 on the surface of the asbestos board 10 at the furnace bottom 1, the high-alumina brick 12 The alumina content is ≥ 48%, which is made of raw materials with high alumina content after molding and calcining; sprinkle a layer of magnesia 11 on the surface of high alumina brick 12 and compact it, and then divide it with brine magnesia Layer thickness ≤ 80mm to knot the furnace ...

Embodiment 3

[0026] like figure 1 and figure 2 As shown, a preparation method of an electric arc furnace comprises furnace bottom 1, furnace cover 2, electrode 3, tapping hole 4, furnace door 5, electrode 3 is inserted into the furnace through the hole on furnace cover 2, and furnace cover 2 is covered in On the furnace bottom 1, a tap hole 4 and a furnace door 5 are formed at the joint between the furnace cover 2 and the furnace bottom 1, and a 5mm, 6mm, 7mm, 8mm, 9mm or 10mm thick asbestos board 10, spread the asbestos board 10 to the furnace door 5 and the tapping hole 4, and lay a layer of high-alumina bricks 12 on the surface of the asbestos board 10 at the furnace bottom 1, the high-alumina brick 12 The aluminum oxide content is ≥ 48%, which is made of bauxite after molding and calcination; spread a layer of magnesia 11 on the surface of high alumina brick 12 and compact it, and then layer with brine magnesia to a thickness of ≤ 80mm Knotting the furnace bottom 1, first knot the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com