Crucible heating device and method

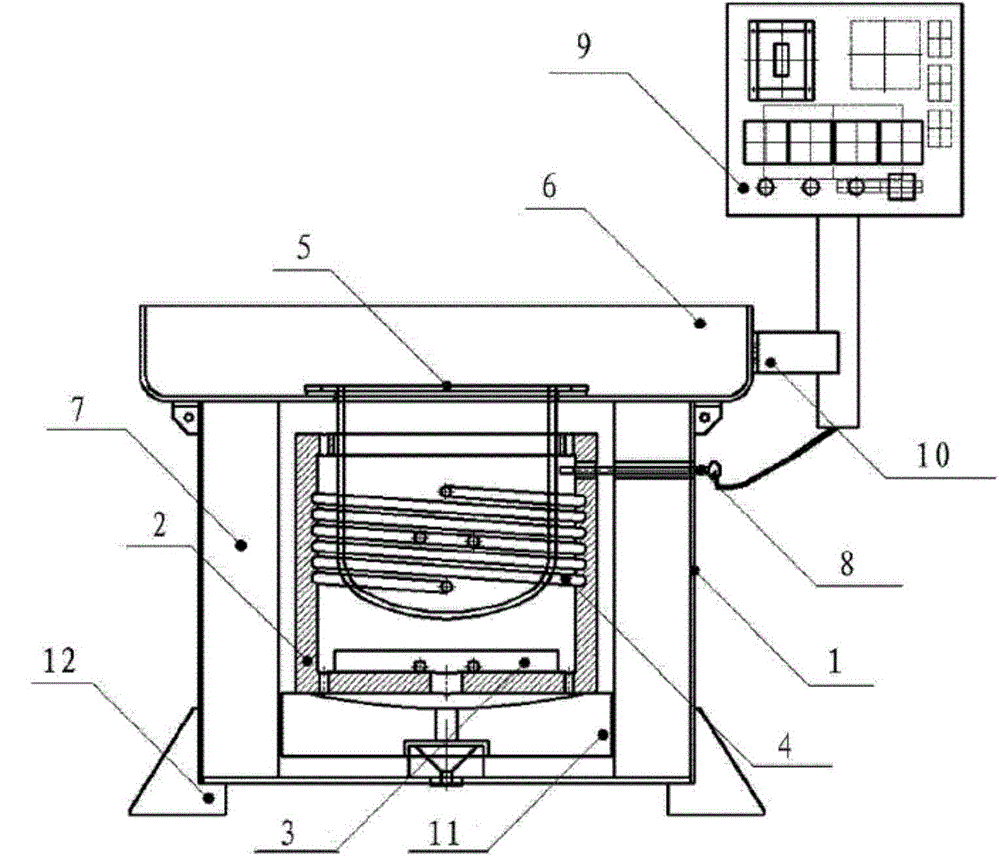

A heating equipment and crucible technology, which is applied in lighting and heating equipment, crucible furnace, electric furnace heating, etc., can solve the problems of uneven temperature and uneven heat transfer, increase the filling amount of materials, reduce the number of cavity openings, and improve the machine table. The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

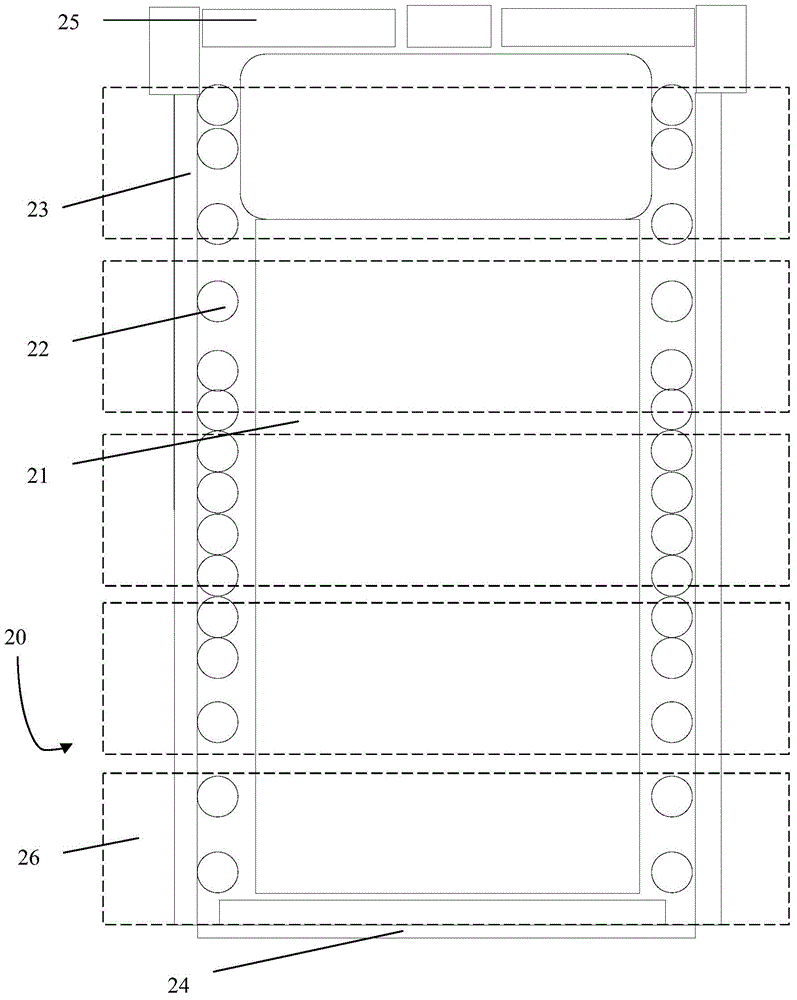

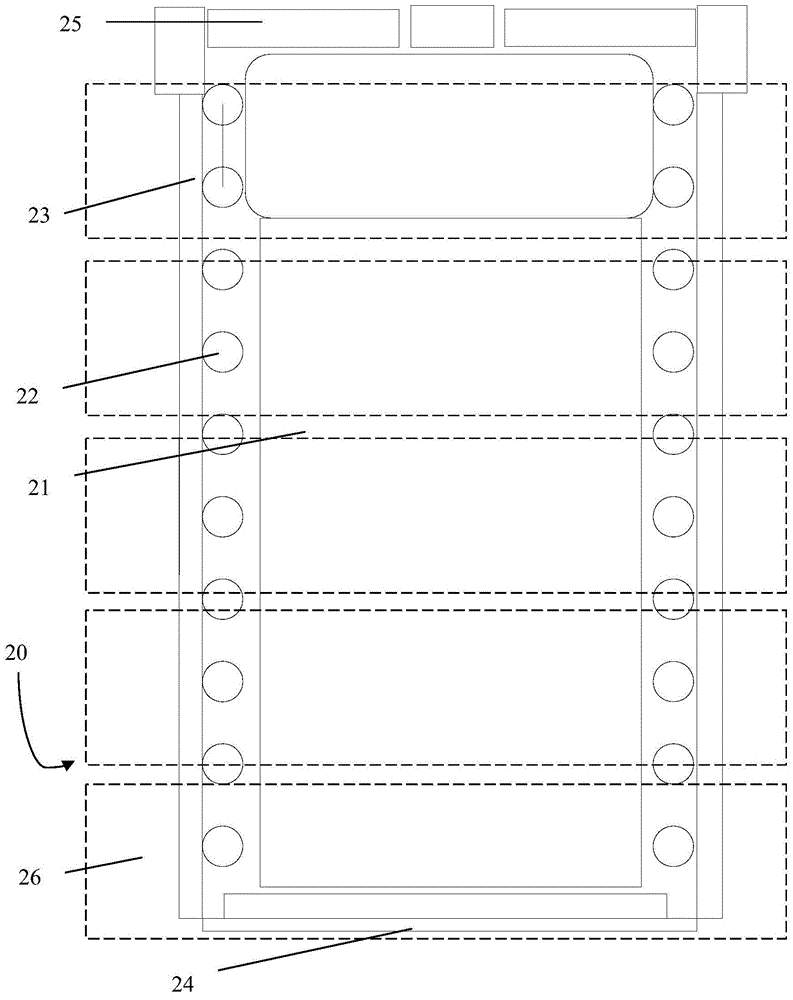

[0037] refer to figure 2 , figure 2 A crucible heating device 20 according to the invention is shown.

[0038]The crucible heating device 20 includes a crucible 21 in which the material to be evaporated is placed.

[0039] The device 20 also includes a metal cylinder 23 surrounding the crucible 21 and a heating wire 22 wound between the metal cylinder 23 and the crucible 21 . The heating wire 22 is used to heat the crucible 21 and the material to be evaporated inside. The temperature at different positions of the crucible 21 is determined by the heat generated by the heating coil of the nearby heating wire 22 . The heating wire 22 is energized to raise the temperature, and the crucible 21 is heated. When a certain temperature is reached, the material in the crucible 21 will evaporate.

[0040] The device 20 also includes a measuring unit and a controller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com