Automobile seat strength testing method with single hydraulic cylinder to act

A car seat and single hydraulic cylinder technology, which is applied in the field of car seat strength testing and can solve the problems of cumbersome test methods and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

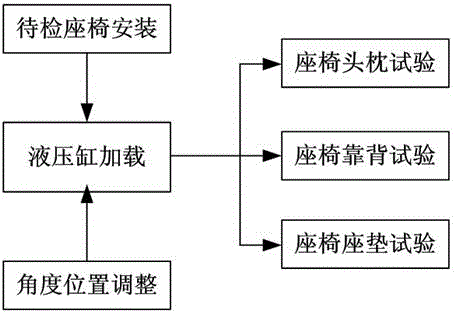

[0021] The automobile seat strength test method of the single hydraulic cylinder effect of the present invention is realized in the following way, see figure 2 As shown, the test method for the strength of a car seat with a single hydraulic cylinder includes four parts: seat installation, hydraulic cylinder loading, angle position adjustment, and car seat test. The car seat test part includes the car seat headrest test. , car seat back test, and car seat cushion test. The three test contents mentioned above are all loaded through the same loading hydraulic cylinder.

[0022] The above scheme is further described below in conjunction with specific examples. It should be understood that these examples are intended to illustrate the present invention and not limit the scope of the present invention. The implementation conditions adopted in the examples can be further adjusted according to specific tests.

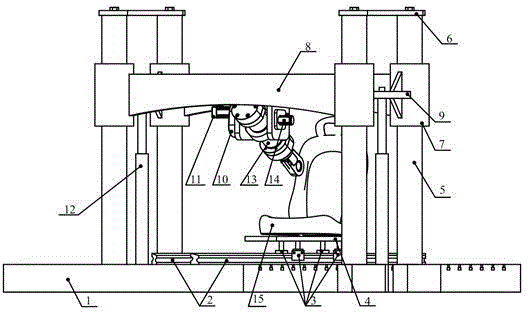

[0023] In the automobile seat strength test method of the single hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com