Hopkinson tension and compression integrated experimental device

An experimental device and experimental technology, which is applied in the field of material mechanical performance experiments, can solve problems such as difficult to meet conditions, cumbersome processing and experimental processes, inconsistent rod cross-sections, etc., and achieve the effects of improved efficiency, convenient replacement, and simplified experimental processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

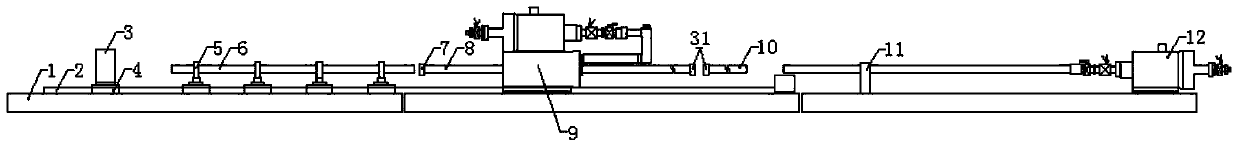

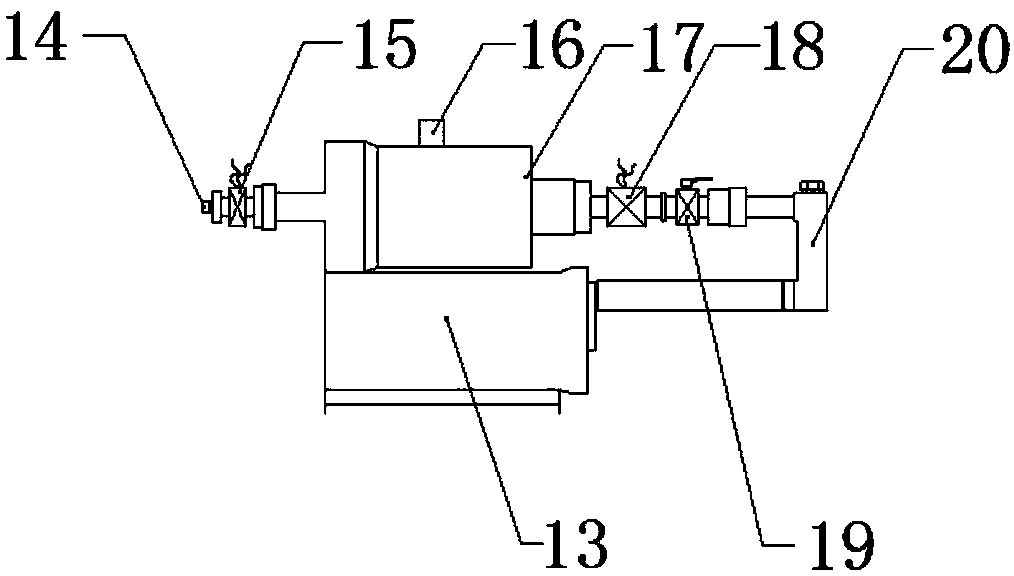

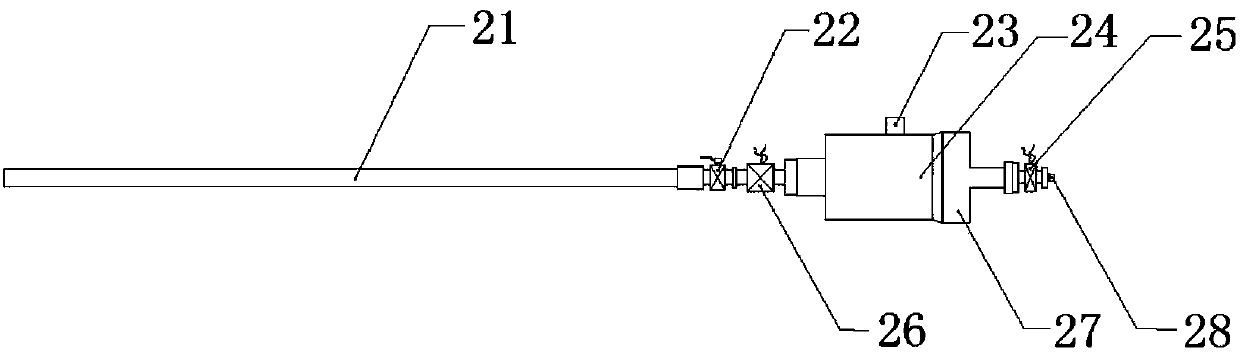

[0017] Combine Figure 1 ~ Figure 5 :

[0018] The invention discloses a Hopkinson tension-compression integrated experimental device. A fixed rail 2, a barrel support 11 and a compression experiment launching device 12 are provided on a water platform 1. The barrel support 11 supports the barrel of the compression experiment launching device 12. The fixed guide rail 2 is provided with a matching sliding block 4, and the matching sliding block 4 is respectively installed with a kinetic energy absorber 3 and a fine adjustment support device 5 from left to right. The fine adjustment support device supports the wave absorption rod 6 and double-end threaded holes from left to right The experimental rod 8 and the single-end threaded hole rod 10, the tensile experiment launching device 9 is set on the fixed guide 2, the double-end threaded hole experimental rod 8 passes through the tensile experiment launching device 9, the flange wave converter 7 is a cylinder Boss structure, threads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com