Sheet inserting machine applied to inductor

A chip insertion machine and inductor technology, applied in transformer/inductor components, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as low efficiency, manpower occupation, affecting product quality and market competitiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in conjunction with the following examples and accompanying drawings.

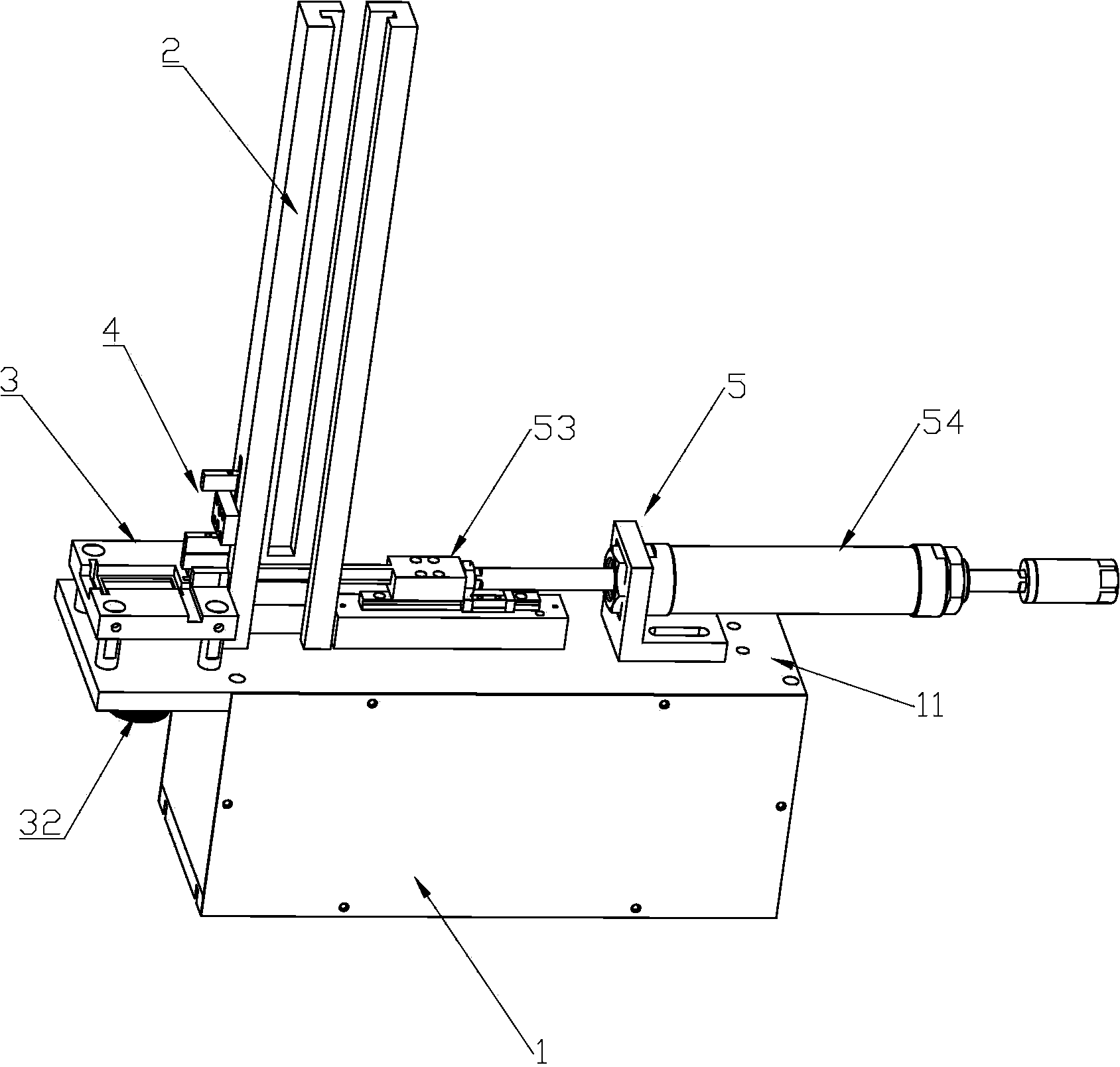

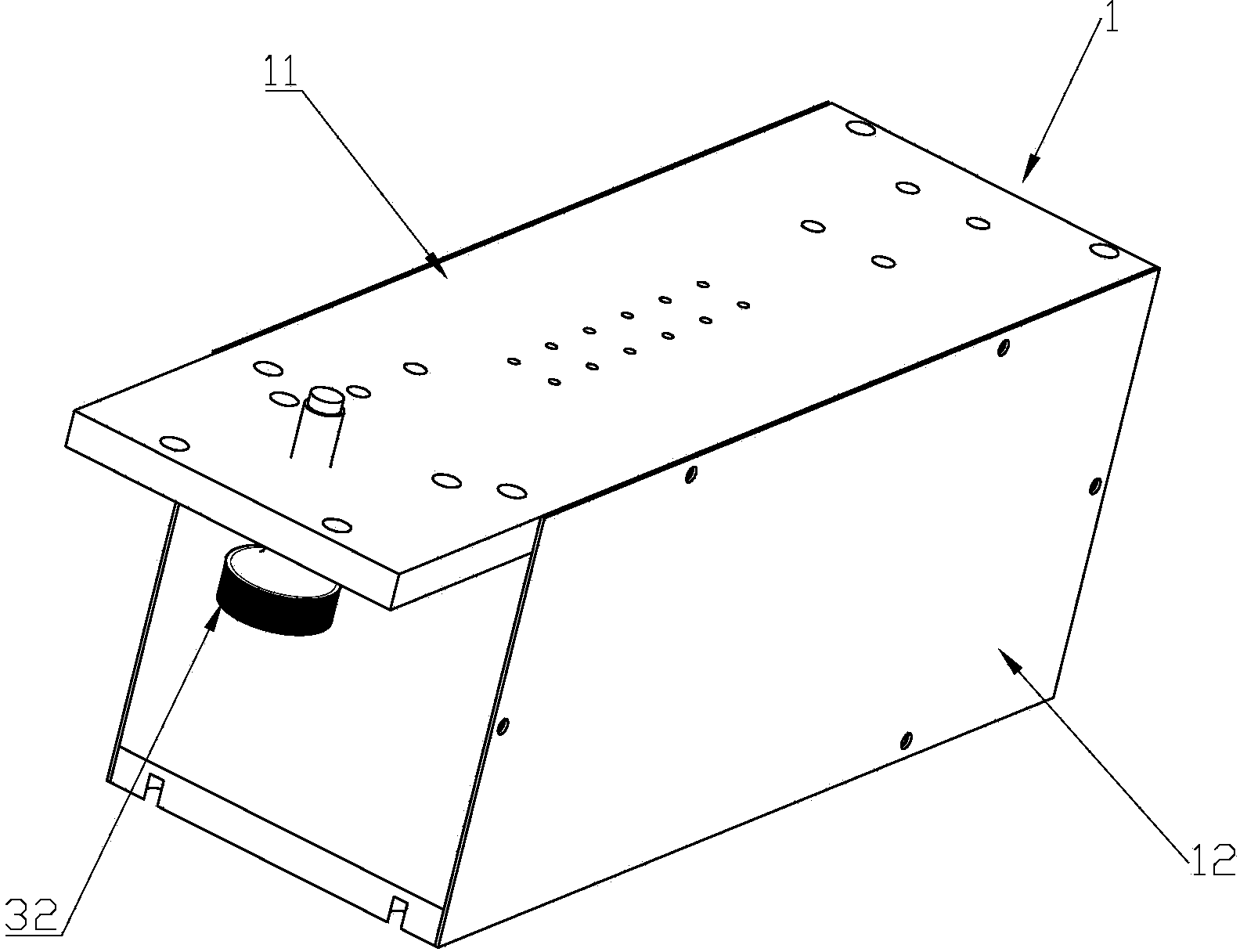

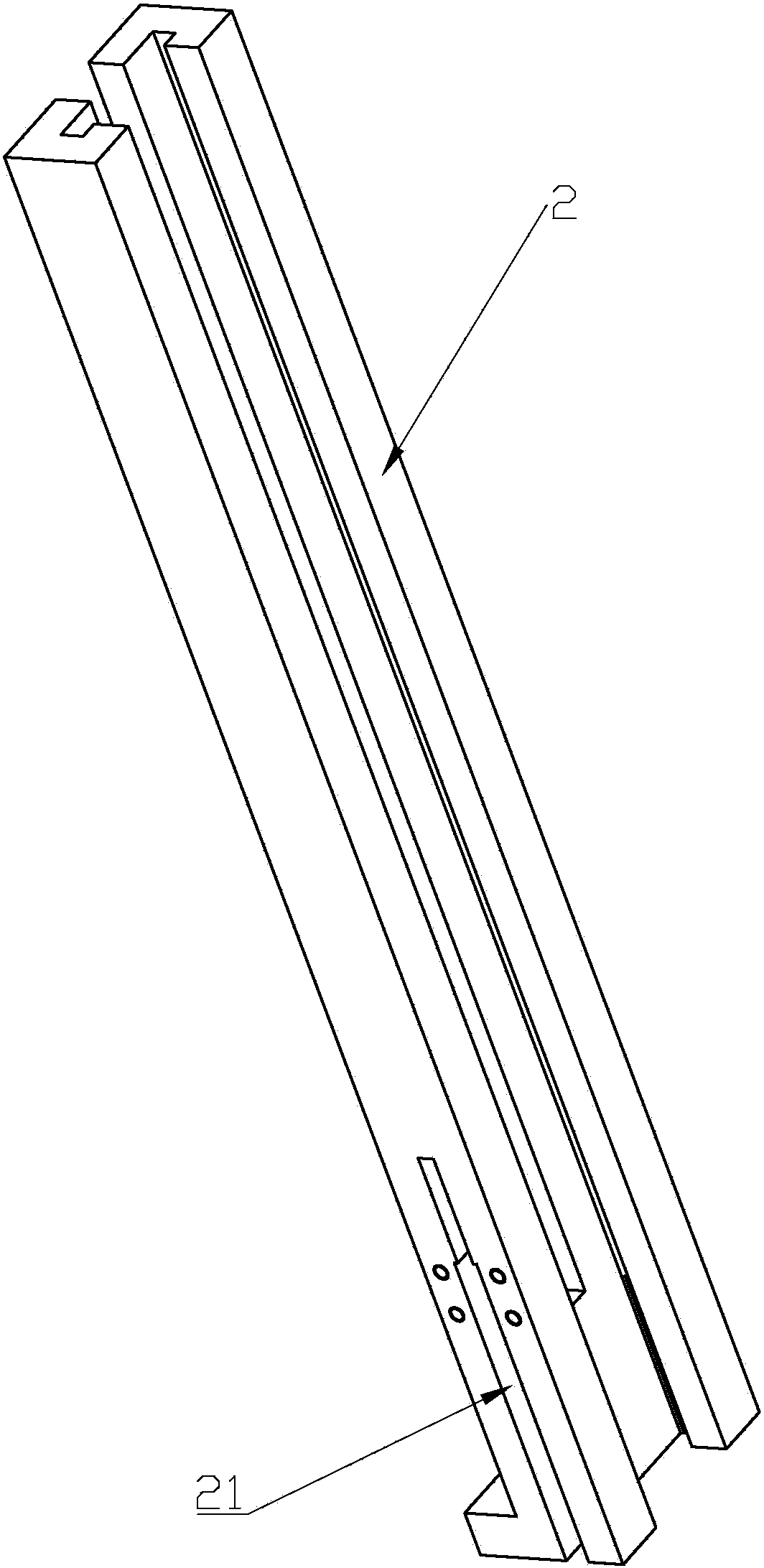

[0042] A chip insertion machine for inductors of the present invention, such as Figure 1 to Figure 7 As shown, it includes a body 1, the body 1 includes a working panel 11 and a cabinet 12 arranged below the working panel 11, and the inserting machine also includes a material guide groove 2 vertically arranged on the working panel 11, and a silicon steel plate installed on the working panel 11. Sheet stack thickness adjusting mechanism 3, slice mechanism 4 and sheet pushing mechanism 5, and the electric control device that is arranged in the cabinet 12; The trough 2 is connected.

[0043] Concretely, the bottom of both sides of the guide groove 2 is provided with a perforation 21, so that the slicer mechanism 4 and the pusher mechanism 5 are all pierced through the guide groove 2, and the silicon steel sheet is pushed out by the pusher mechanism 5 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com