Lead frame with inclined bending portion

A lead frame and lead frame technology, which is used in semiconductor/solid-state device parts, electrical components, electric solid-state devices, etc., can solve the problems of uneven stress on materials, skewed base surface of lead frames, and difficulty in industrialized large-scale production. To achieve the effect of reducing production costs and avoiding defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

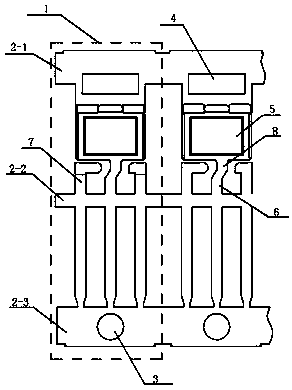

[0018] Such as figure 1 , figure 2 with image 3 As shown, a lead frame with a bent part and an inclined part is composed of thirty lead frame units 1 connected in a single row. The frame unit 1 includes a positioning hole 3, a heat sink 4, a base body 5 and lead pins. The positioning hole 3 is provided on the connecting piece 2-3, and the diameter of the positioning hole 3 is 2.0 mm. The base body 5 has a width of 4 mm and a width of 2.8 mm.

[0019] The heat sink 4 is arranged on the connecting piece 2-1, and the lead pins include the middle lead pin 6 and the side lead pin 7, and the width of the middle lead pin 6 or the side lead pin 7 is 0.81mm

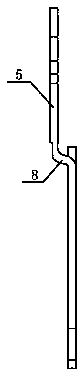

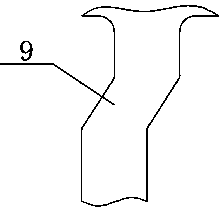

[0020] The middle lead pin 6 is fixedly connected to the base body 5 through the bonding part 8, the bond part 8 is bent, and the middle lead pin 6 and the side lead pin 7 are fixedly connected throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com