A kind of water surface ship pier method with flexible material laid on the outer surface

A flexible material and outer surface technology, applied in ship parts, ship construction, ships, etc., can solve the problems of non-metallic flexible materials that cannot bear the weight of piers, large deformation, etc., to achieve the effect of convenient construction, easy maintenance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

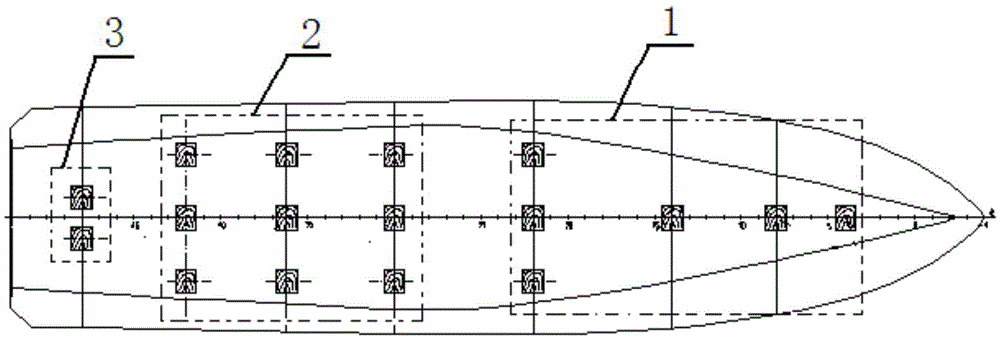

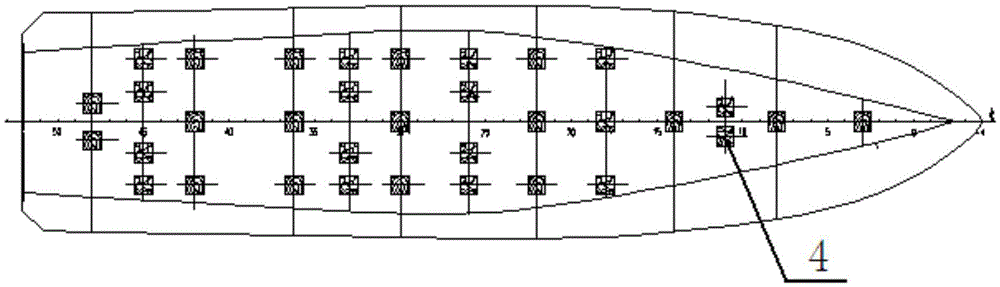

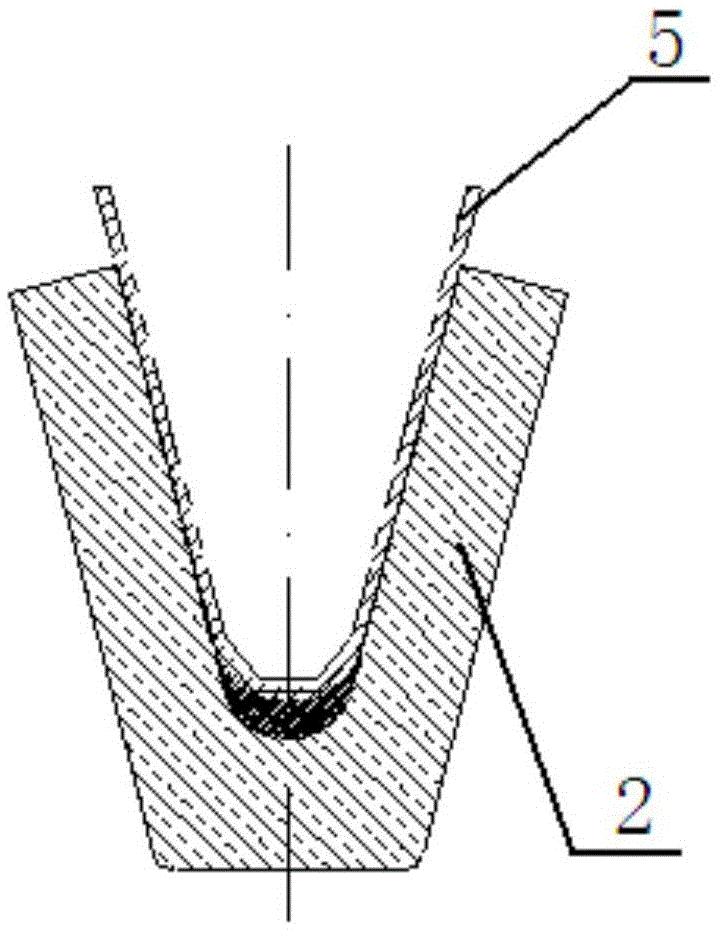

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0022] This embodiment provides a water surface ship pier method with flexible materials laid on the outer surface, so that the water surface ship covered with flexible materials on the outer surface can also realize the pier, and the process is simple and the construction is convenient; the ship can be repeatedly docked The pouf is beneficial to the maintenance of the ship.

[0023] The scheme adopted in the method is that when the ship is built, before the flexible material is laid on its outer surface, the pouf tile is first laid on the pouf position, so that the pouf is loaded by the pouf tile when the ship is docked for maintenance. Since the hull plate 5 is a curved surface, especially the shape of the bow and stern changes drastically, in order to ensure the smooth shape of the underwater part of the ship and reduce the navigation resistance, when l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com