Rotor bearing for electrical machine

一种转子、发电机的技术,应用在机电装置、风力电机组合、旋转运动的轴承等方向,能够解决无法有利地使用风力发电设备等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

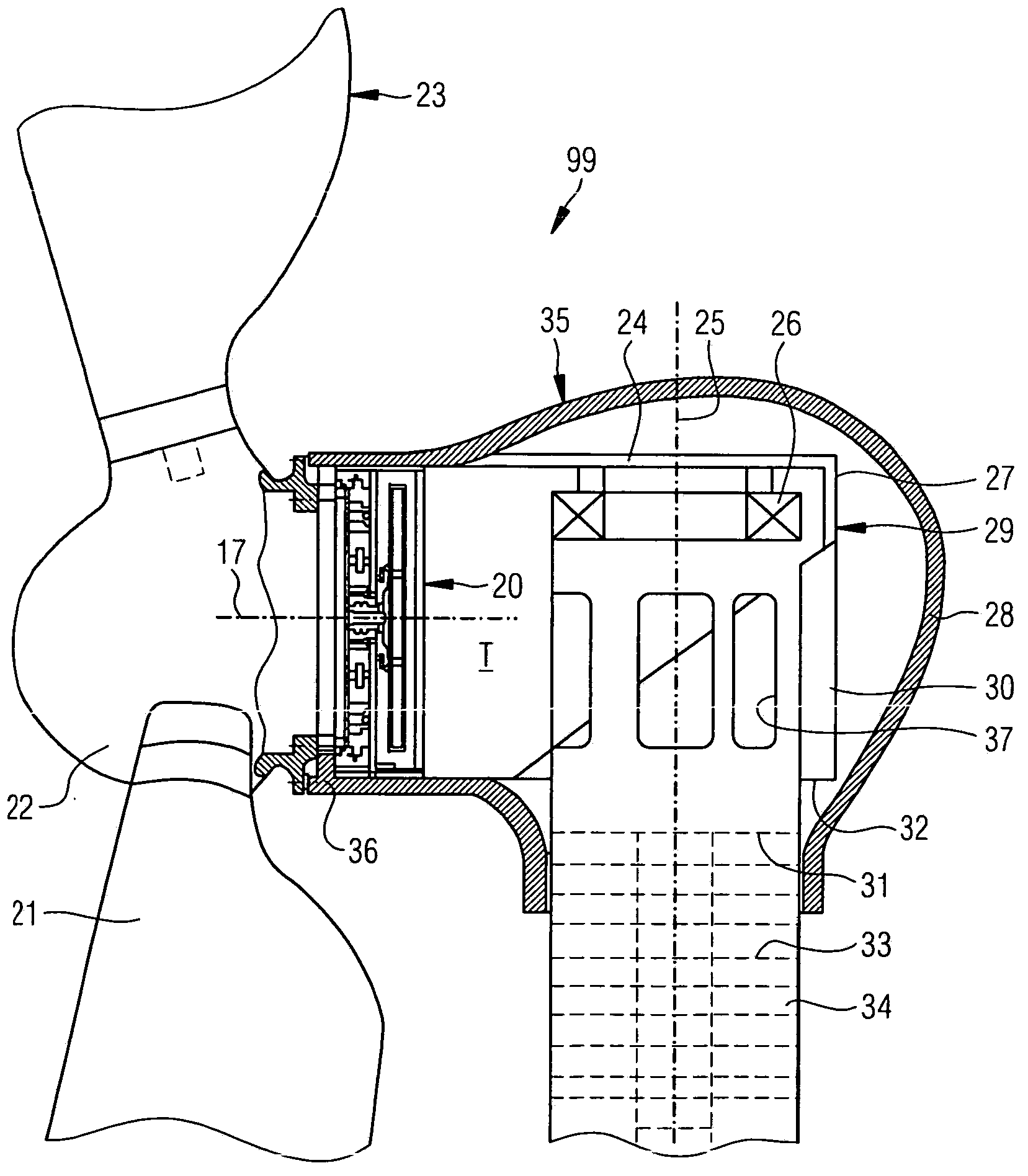

[0042] exist figure 1 The structure of a nacelle 35 of a wind power plant 99 which is suitable for using a disk rotor generator according to the invention is depicted in .

[0043] Here the upper end of the tower 34 with a circular cross section is seen, the nacelle 35 being pivotably fitted about the vertical tower axis 25 via the machine room bearing 26 mounted in the horizontal position for orientation adjustment on the upper end. If one ring of the machine room bearing 26 is fixed on the upper side of the tower 34 , then the other ring can be pivoted about the tower axis 25 by means of a drive not shown.

[0044] An upper plate or frame 24 of a load-bearing structure 29 pivotable about a tower axis 25 is supported on a pivotable ring of machine room bearings 26 . The carrier structure 29 forms, so to speak, the inner shell of the machine room 35 and is accessible by maintenance personnel via a lift, a ladder 33 or stairs in the tower 34 and via a lateral exit 37 in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com