Design improvements for flux switching machines

A magnetic flux, switching motor technology, used in electronically commutated motor control, synchronous motors for single-phase currents, magnetic circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

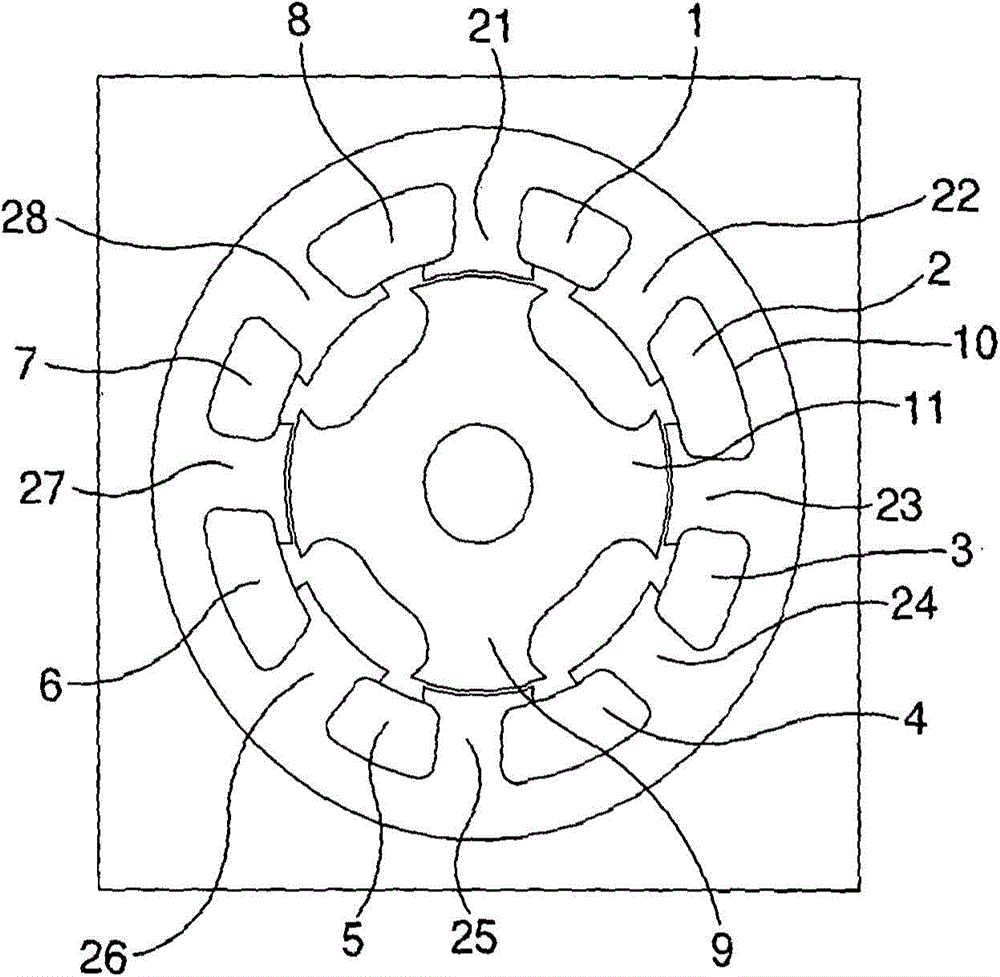

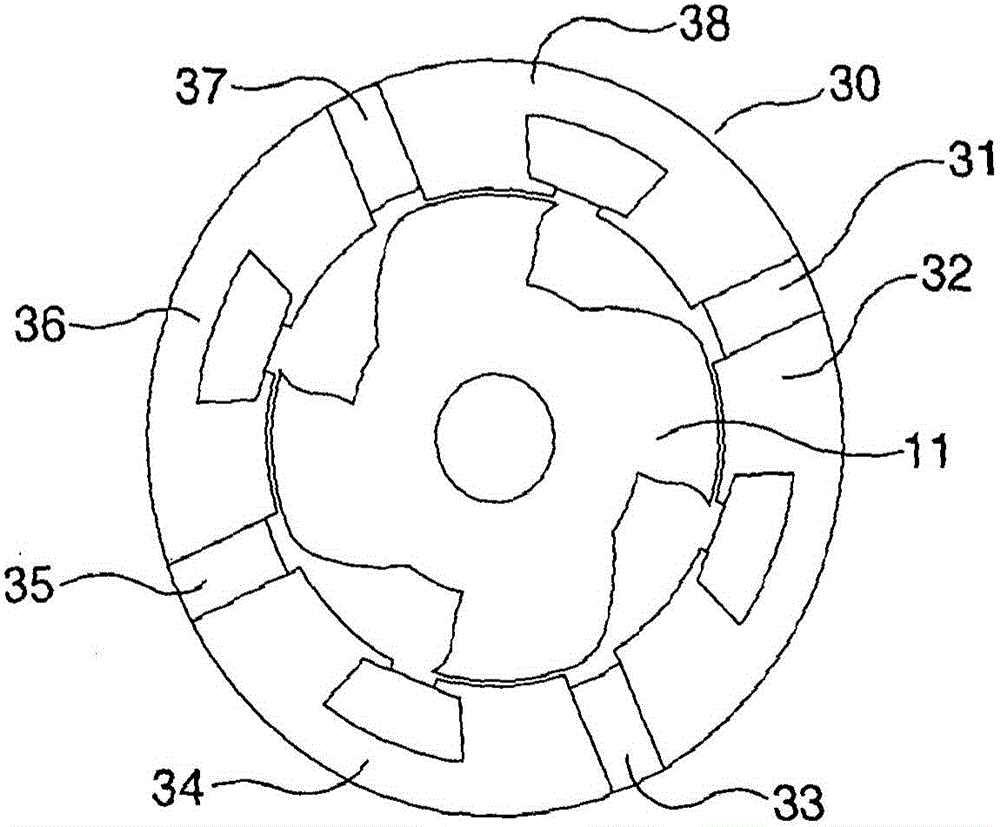

[0069] Image 6 The rotor is shown. Slotted models have been cut into rotor laminations. The slots 210 are shaped to reinforce the 4-pole pattern on the rotor. These slots introduce air between the steel segments and thus have high magnetic permeability. It is now more difficult for magnetic flux to permeate at right angles to the slot than permeate parallel to the slot. exist Image 6 , there are 4 sets of slots in each rotor tooth, and these slots are arranged in two pairs linked with corresponding pairs on adjacent rotor teeth. Such slots are proposed for synchronous reluctance motors in order to improve the ratio between direct and quadrature inductance.

[0070] Its use in flux switching motors has never been suggested because introducing air into the stator teeth would be seen as detrimental to inductance when the rotor teeth are in a position aligned with a set of stator teeth. To maintain mechanical rigidity, it is advantageous to leave some material 211 to bridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com