Press fitting equipment and method for rubber ring of torsion damper

A torsional shock absorber and rubber ring technology, applied in hand-held tools, manufacturing tools, etc., can solve problems such as low production efficiency, affecting product quality, and poor stability, and achieve high production efficiency, compact structure, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

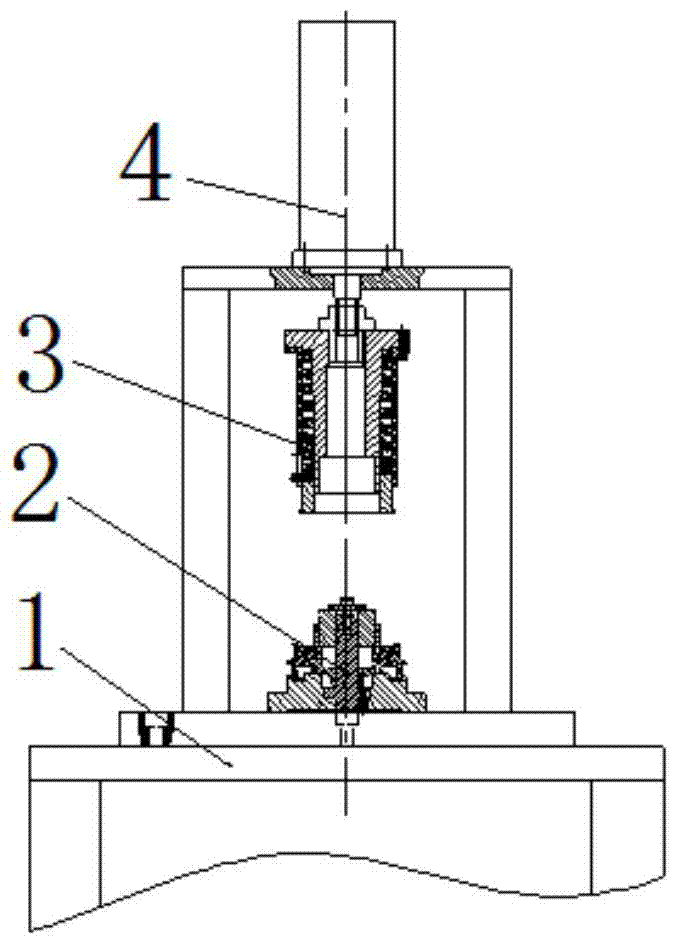

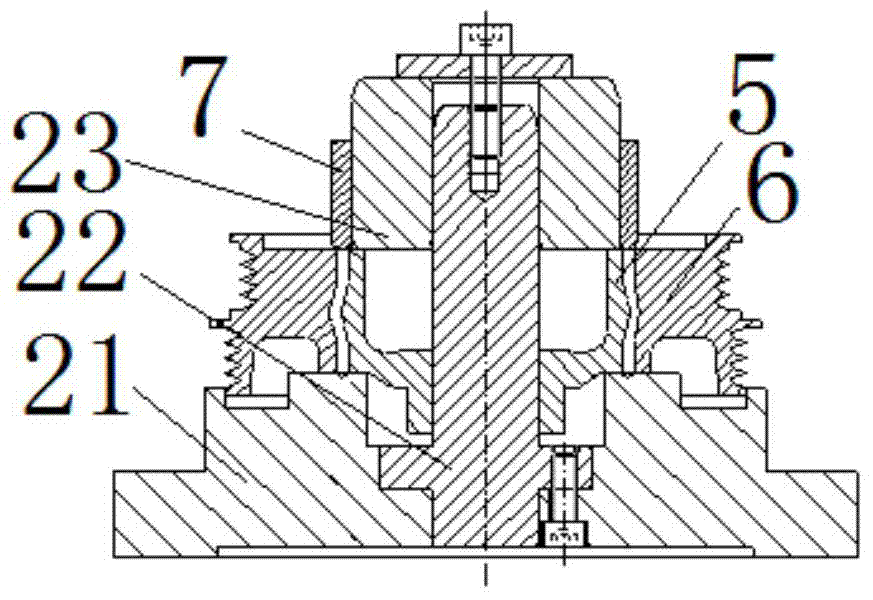

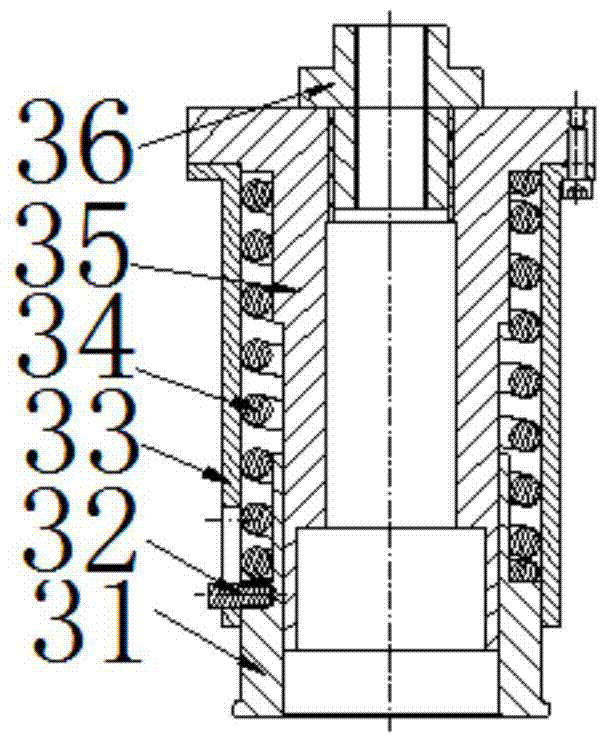

[0027] Such as Figure 1 to Figure 4 As shown, the torsional shock absorber rubber ring press-fitting equipment includes a positioning clamping mechanism 2, a press-fitting mechanism 3 and a hydraulic cylinder 4 that provides press-fitting pressure.

[0028] The positioning clamping mechanism 2 includes a positioning base 21, a positioning mandrel 22, and a rubber ring positioning seat 23. The positioning base 21 is fixed on the workbench 1, and the center of the positioning base 21 is provided with a groove, and the positioning mandrel 22 is fixed on the positioning base by bolts. 21 central grooves, the positioning base 21 is provided with a positioning groove for positioning the inertia ring 6, the positioning groove is an annular groove, and the positioning mandrel 22 top is fixed with a ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com