Welding process of medical filters

A welding process and filter technology, which is applied in the field of medical equipment assembly, can solve problems such as the adverse effects of ultrasonic welding machinery precision, and achieve the effects of preventing mutual detachment, low precision requirements, and increased adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

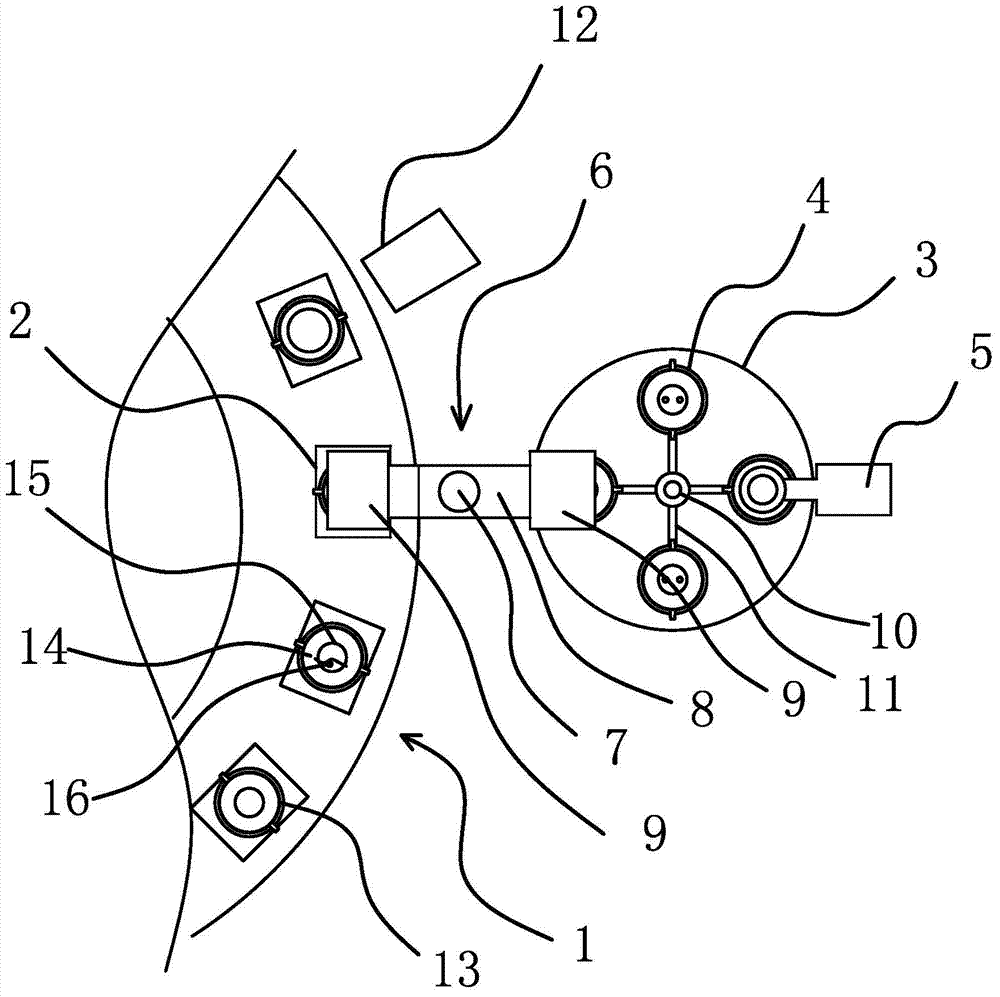

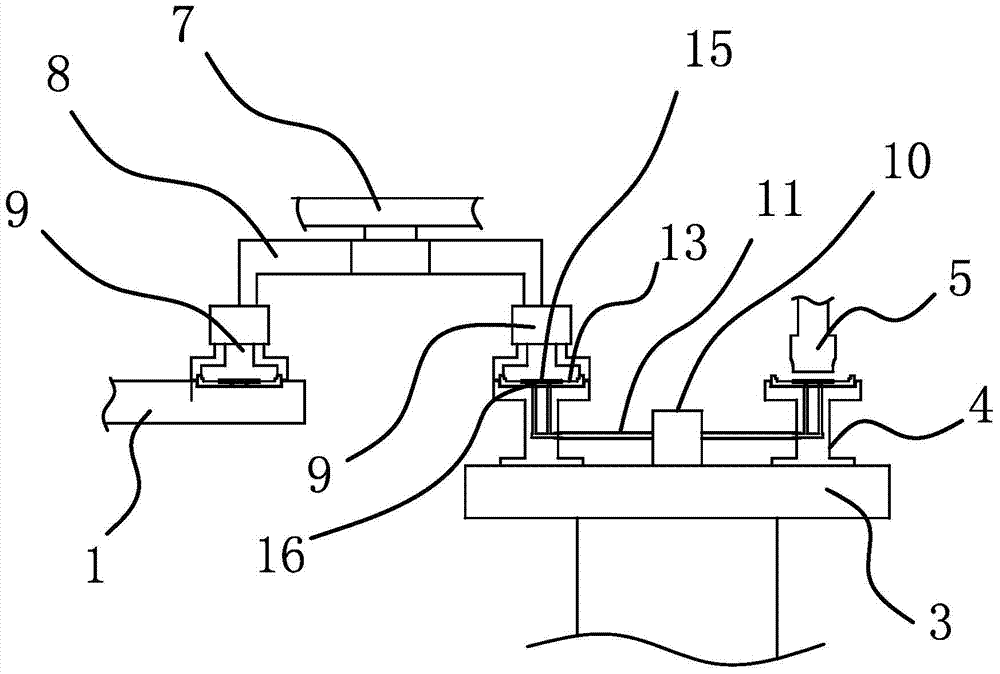

[0024] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0025] Such as figure 1 with figure 2 As shown, the filter 13 includes a membrane tank 14 and a filter membrane 15. The filter membrane 15 is located in the membrane tank 14, and the upper side wall of the membrane tank 14 is provided with micropores 16.

[0026] This welding process includes the following procedures:

[0027] a. Loading the filter 13: set up an assembly platform 1 with a number of assembly stations 2 on the assembly platform 1, fix the filter 13 on the assembly station 2, and a welding platform 3 on one side of the assembly platform 1. , The welding platform 3 is provided with a number of support seats 4, and a material moving mechanism 6 is provided between the assembly platform 1 and the welding platform 3. The filter 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com