Automatic catering sewage treatment equipment and treatment method thereof

A technology for catering sewage and treatment equipment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Reasonable, small size, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

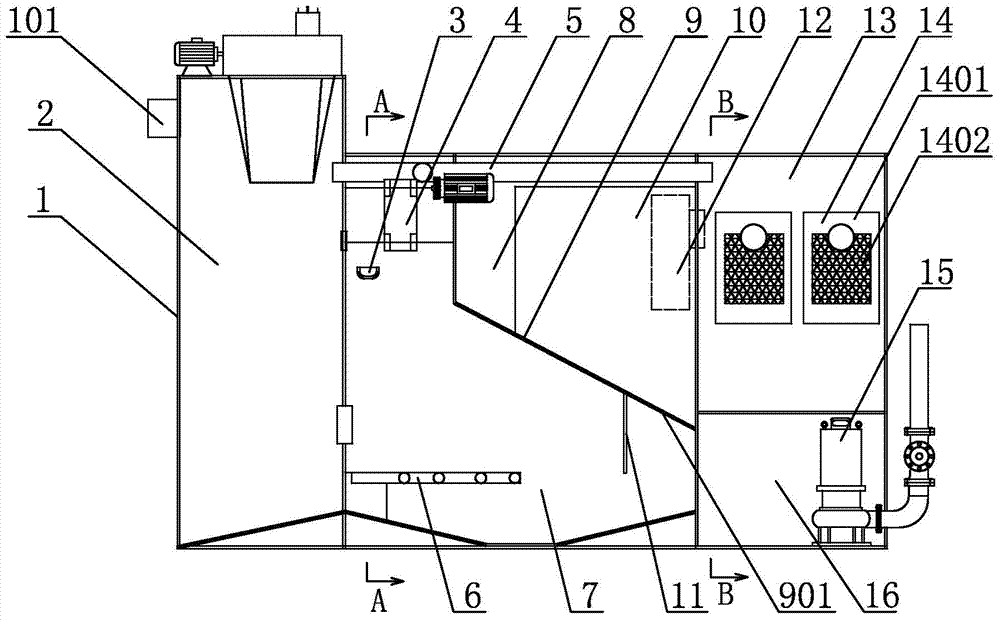

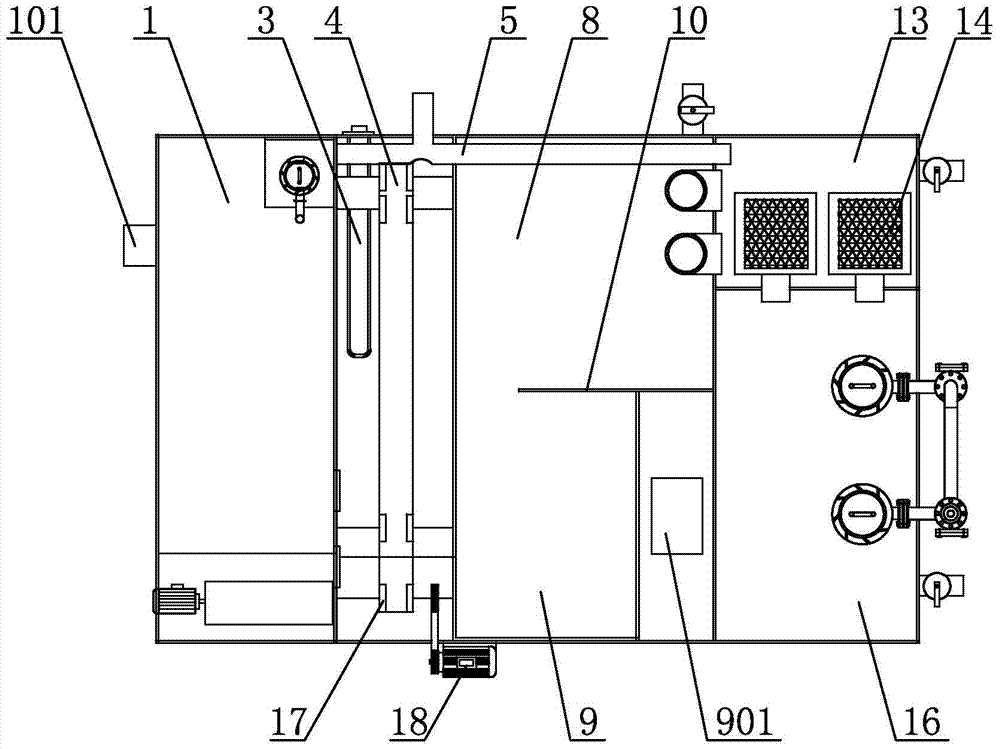

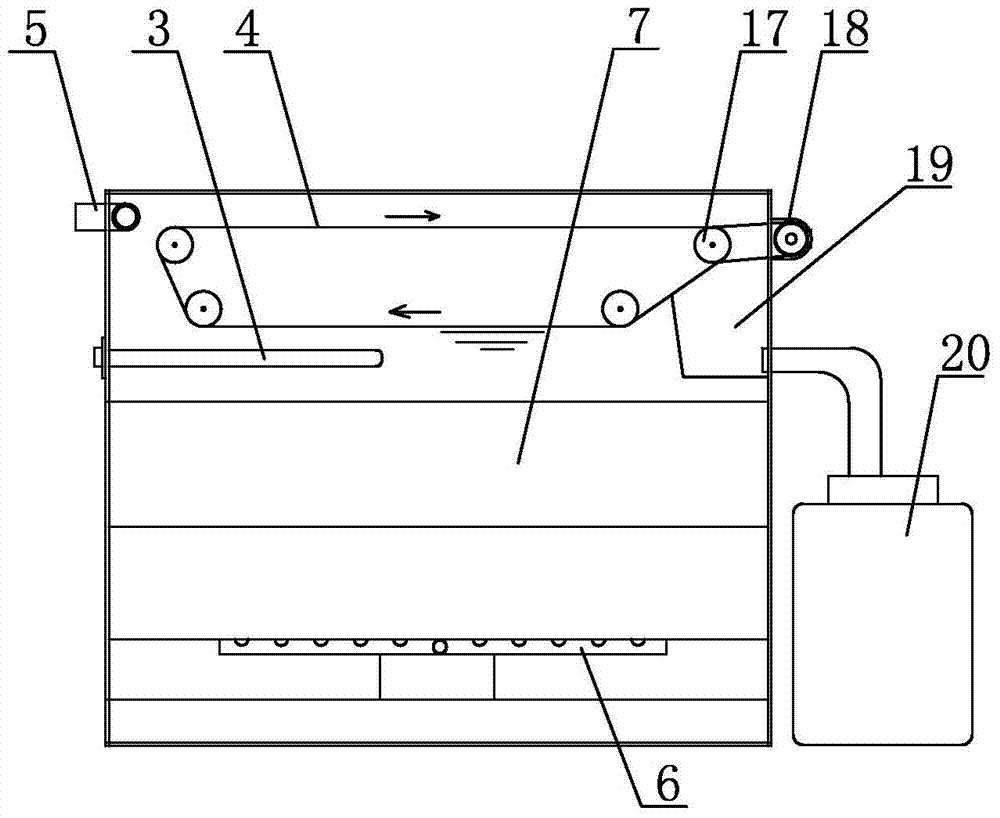

[0024] Now in conjunction with accompanying drawing, the present invention will be further described.

[0025] Such as Figure 1~5 As shown, the automatic catering sewage treatment equipment includes a box body 1, a slag removal device, a dosing device, an oil removal device, a filter processor 14, and a sewage lifting pump 15. The tank is separated by a partition to form a slag removal chamber 2, an oil-water separation chamber, a filtration treatment chamber 13, and a sewage discharge chamber 16. The chambers are connected through water pipes, and the bottoms of the slag removal chamber and the oil-water separation chamber are designed as inverted cones. , and external slag discharge pipe.

[0026] The slag removal device is a grill controlled by a motor, which is installed below the water inlet of the water inlet pipe 101 in the slag removal chamber, and is used to intercept various large solid impurities in the water, such as rice grains, bones, fruit peels, etc., so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com