Method for Producing Seedling Substrate Using Tobacco Waste

A technology for tobacco waste and seedling substrate, applied in the field of producing seedling substrate, can solve problems such as pollution, and achieve the effects of improving soil microbial activity, reducing soil bulk density, and strong killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Collection and crushing: Most of the unsuitable tobacco leaves contain pathogenic bacteria and insect eggs. Firstly, the unsuitable tobacco leaves are collected in a closed way to reduce the pollution of diseases and insect pests to the tobacco field, and are pulverized by a shredder.

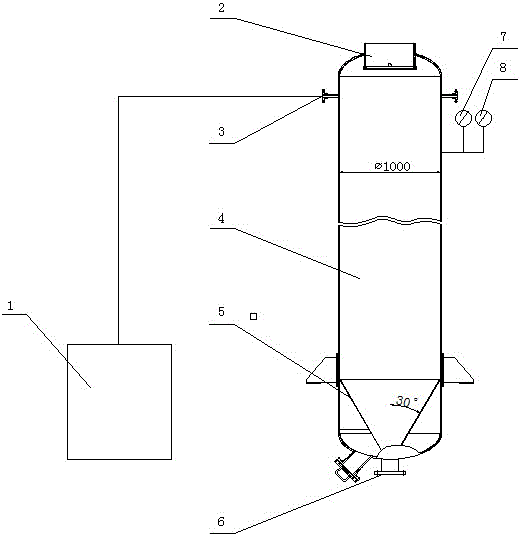

[0052] (2) High-temperature and high-pressure separation treatment: After collecting and crushing unsuitable tobacco leaves, transport them to the filling port of the separation tank with an elevator, and then reach the inside of the separation tank, raise the temperature of the raw materials in the container to 158-164 °C, and the steam pressure reaches 0.5-0.6Mpa, after 1 minute, quickly open the outlet to complete the high temperature sterilization.

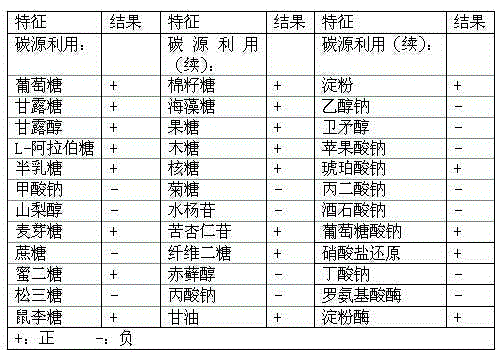

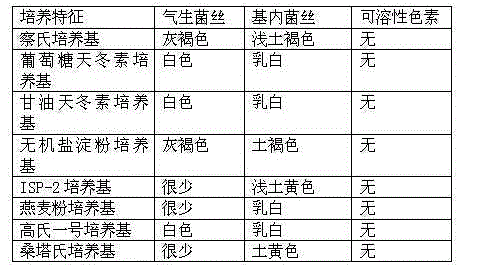

[0053] (3) In the fermentation step, the separated unsuitable tobacco leaves, nutrient source substances and auxiliary materials are mixed in a mass ratio of 70:10:20, the water content is adjusted to 50-60%, and 0.5-1‰ of the total a...

Embodiment 2

[0070] (1) Collection and crushing: Most of the unsuitable tobacco leaves contain pathogenic bacteria and insect eggs. Firstly, the unsuitable tobacco leaves are collected in a closed way to reduce the pollution of diseases and insect pests to the tobacco field, and are pulverized by a shredder.

[0071] (2) High temperature and high pressure separation treatment: After collecting and crushing unsuitable tobacco leaves, transport them to the filling port of the separation tank with an elevator, and then reach the inside of the separation tank, raise the temperature of the raw materials in the container to 158°C, and the steam pressure to about 0.6 , After 50 seconds, quickly open the outlet to complete the high temperature sterilization.

[0072] (3) In the fermentation step, the separated unsuitable tobacco leaves, nutrient source substances and auxiliary materials are mixed in a mass ratio of 70: 20: 10, the water content is adjusted to 60%, and 1‰ of the total amount of ferm...

Embodiment 3

[0080] (1) Collection and crushing: Most of the unsuitable tobacco leaves contain pathogenic bacteria and insect eggs. Firstly, the unsuitable tobacco leaves are collected in a closed way to reduce the pollution of diseases and insect pests to the tobacco field, and are pulverized by a shredder.

[0081] (2) High-temperature and high-pressure separation treatment: After collecting and crushing unsuitable tobacco leaves, transport them to the filling port of the separation tank with an elevator, and then reach the inside of the separation tank, raise the temperature of the raw materials in the container to 158°C, and the steam pressure to 0.5Mpa , After 30 seconds, quickly open the discharge port to complete the high temperature sterilization.

[0082] (3) In the fermentation step, the separated unsuitable tobacco leaves, nutrient source substances and auxiliary materials are mixed in a mass ratio of 75:15:10, the water content is adjusted to 500%, and 0.5‰ of the total amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com