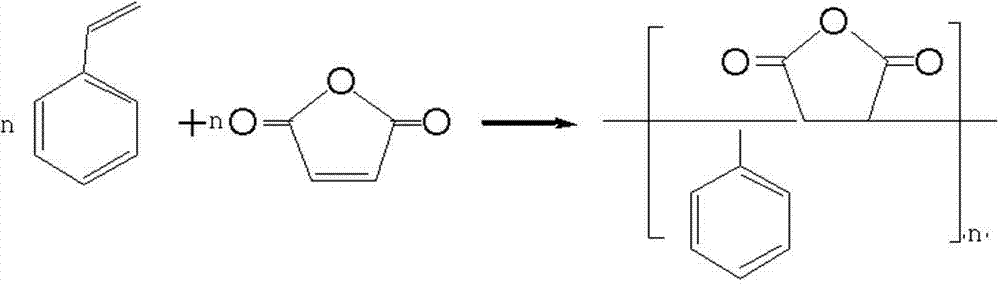

Styrene-maleic anhydride grafted polyethylene glycol and preparation method thereof

A technology of grafting polyethylene glycol and maleic anhydride, which is applied in the preparation of polymers and the field of polycarboxylic acid-based water reducers, which can solve the problem of reduced effect of water reducers, difficulty in controlling the distribution of branched chains, and the reduction of water reducers. effect and other issues to achieve the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 2:

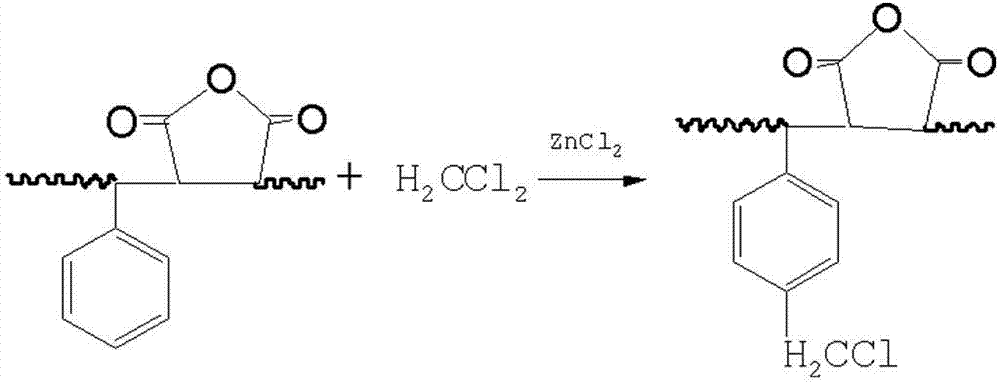

[0054] (1) Slowly add 4.4ml of lyre and 6g of Malaysic acid anhydride solution to 70ml toluene, slowly add it to the reactor, and heated slowly. When the temperature rises to 90 ° C, the 30ml 0.005g oxidation benzohydraxidyl -dioxide solutionSlowly drip into the reactor, the titration time is 1h, the reaction temperature is 90 ± 1 ℃, and the reaction time is 7h.After the reaction is over, use toluene and petroleum ether mixed solutions to washed and refined solid powder. By decompression filtering, white powder is obtained, and SMA will be refined, and at 80 ° C, the decompression is dry for 10h.Get the SMA with the average molecular weight of 410.

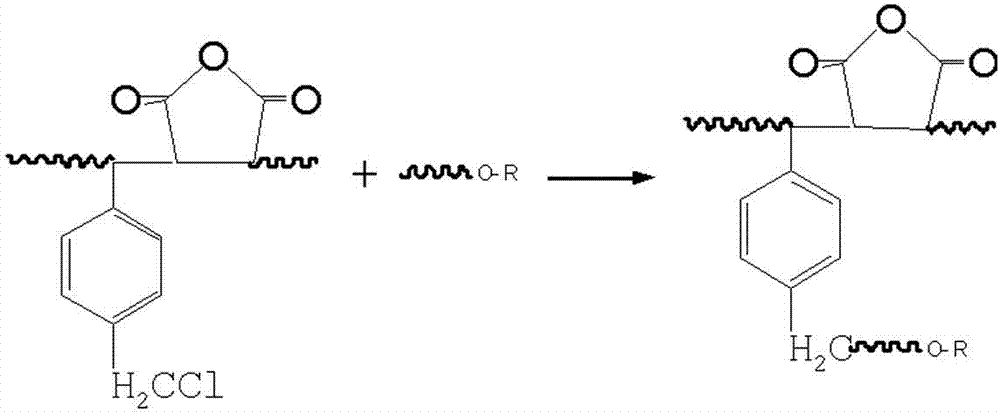

[0055] (2) Under 50 ° C, dissolve the refined SMA at 1 w Among the % concentrated sulfuric acid solution, it is acidified, the treatment time is 2H, and the polymer obtained by the decompression is filtered with a 75ml 0.9g zinc chloride, 2ml dichlogenne, and 2ml dichloroethylene solution to add the reactor.Slowly ...

Embodiment 2

[0057] Example 3:

[0058] (1) Slowly add 5.5ml styrene and 5.2g Malayanine solution solution in 70ml toluene slowly added to the reactor and heat it slowly. When the temperature rises to 90 ° C, the 30ml of 0.029g peroxide oxide is theThe solution is slowly drip into the reactor, the titration time is 30min, the reaction temperature is 90 ± 1 ℃, and the reaction time is 8H.After the reaction is over, use toluene and petroleum ether mixed solutions to washed and refined solid powder. The white powder is obtained by decompression filtering, that is, refined SMA, and at 80 ° C, the decompression is dry for 24 hours.Get the SMA with the average molecular weight of 360.

[0059] (2) Under 50 ° C, the refined SMA is dissolved in a 1W % concentrated sulfate solution for acidification treatment, the treatment time is 2H, and the polymer obtained by the decompression is filtered.The solution is added to the reactor together, slowly heating to 50 ° C, the reaction temperature is 60 ± 1 ° C...

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap