Fabric with low friction coefficient and application thereof

A technology with low friction coefficient and sliding friction coefficient, which is used in fabrics, textiles, textiles and papermaking, etc., can solve the problems of increasing process difficulty, shortening service life, easy to be worn through, etc., to achieve good wear resistance and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

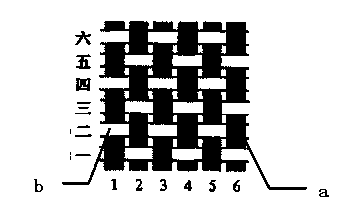

Embodiment 1

[0050] The warp yarn adopts polytetrafluoroethylene untwisted filaments with a denier of 440dtex, the number of single filaments is 60, and the friction coefficient between silk and silk is 0.065. The weft yarn adopts a denier of 470dtex, the number of single filaments is 72, and the tensile strength is 39.8 N, the nylon 66 full-drawn silk that elongation at break is 23.3%, is woven by rapier loom, makes the plain weave fabric that warp density is 62 / inch, and weft density is 62 / inch. Wherein, the polytetrafluoroethylene weave points account for 50% of the total weave points of the fabric as the friction surface, and the polytetrafluoroethylene weave points account for 50% on the other side of the fabric, which is used as the bonding surface. And the prepared fabric is placed under the conditions of temperature 20±2°C and humidity 65±4% for humidity conditioning treatment. The properties of the fabric were evaluated and are shown in Table 1.

Embodiment 2

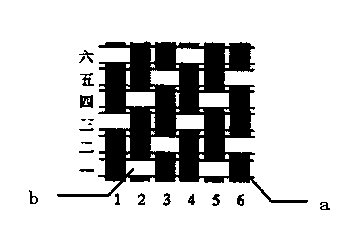

[0052] The warp yarn adopts polytetrafluoroethylene untwisted filaments with a denier of 440dtex, the number of single filaments is 60, and the friction coefficient between filaments is 0.065. , weaving by rapier loom to obtain a 3 / 1 warp twill fabric with a warp density of 90 threads / inch and a weft thread density of 120 threads / inch, wherein the polytetrafluoroethylene weave points account for 75% of the total weave points of the above-mentioned fabric One side of the fabric is used as the friction surface, and the polytetrafluoroethylene tissue points account for 25% on the other side of the fabric, which is used as the bonding surface. And the prepared fabric is placed under the conditions of temperature 20±2°C and humidity 65±4% for humidity conditioning treatment. The properties of the fabric were evaluated and are shown in Table 1.

Embodiment 3

[0054] The warp yarn adopts polytetrafluoroethylene untwisted filaments with a denier of 890dtex, the number of single filaments is 120, and the friction coefficient between silk and silk is 0.071; the weft yarn adopts a denier of 470dtex, the number of single filaments is 136, and the tensile strength is 40.9 N. Nylon 66 full-drawn yarn with an elongation at break of 22.8%, is woven by a rapier loom to obtain a 2 / 1 warp-face twill fabric with a warp density of 60 threads / inch and a weft density of 90 threads / inch , wherein the polytetrafluoroethylene weave points account for 66.7% of the total weave points of the above fabric as the friction surface, and the polytetrafluoroethylene weave points account for 33.3% on the other side of the fabric, which is used as the bonding surface. And the prepared fabric is placed under the conditions of temperature 20±2°C and humidity 65±4% for humidity conditioning treatment. The properties of the fabric were evaluated and are shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com