A selective mining process and its equipment

A selective and equipment technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of inability to carry out wireline operations, high operating costs, and difficulty in separate mining, and achieve good comprehensive economic benefits, Reliable connection and obvious overall benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

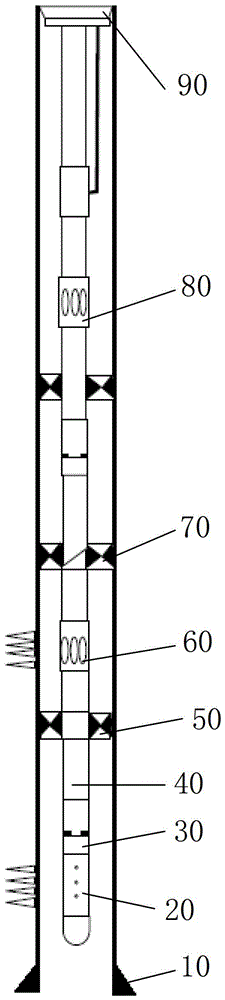

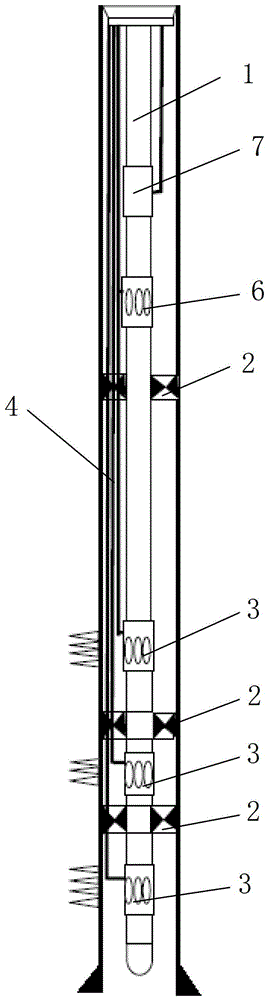

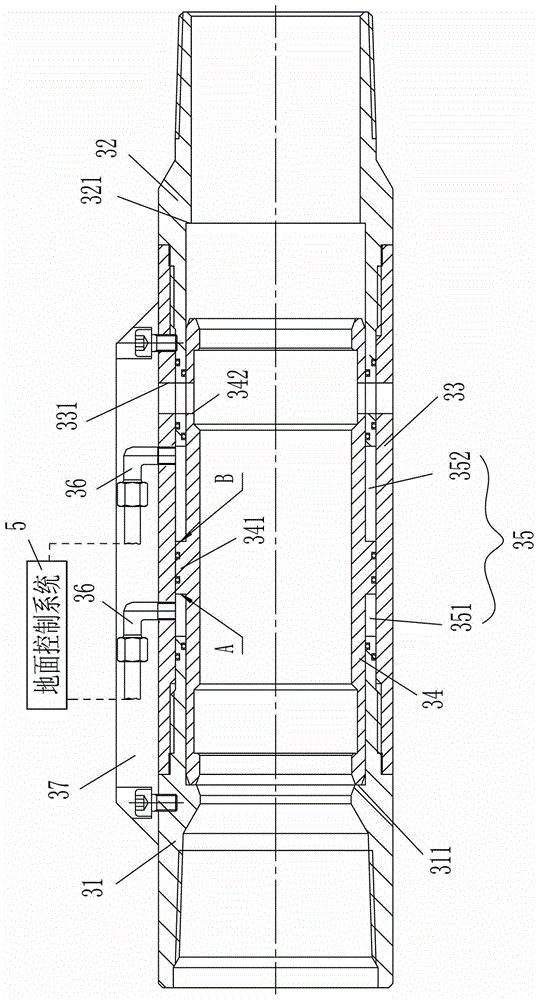

[0069] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0070] see figure 2 , figure 2It is a structural schematic diagram of the selective mining equipment of the present invention. The selective production equipment of the present invention includes a layered tubing string 1 and a packer 2, the packer 2 is used to separate the oil layers of the oil well, the packer 2 is installed on the layered tubing string 1 and Set at the separation of the oil layers, the layered pipe string 1 is also provided with a plurality of hydraulic control switch sliding sleeves 3, and the hydraulic control switch sliding sleeves 3 are connected to the layered pipe string 1 and correspond to The oil layer is arranged, and the multiple hydraulic control switch sliding sleeves 3 are respectively connected to the ground control system 5 through the control pipeline 4, and the ground control system 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com