Diesel fuel leakage control system for dual fuel injector

An injector, dual-fuel technology for leaky systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

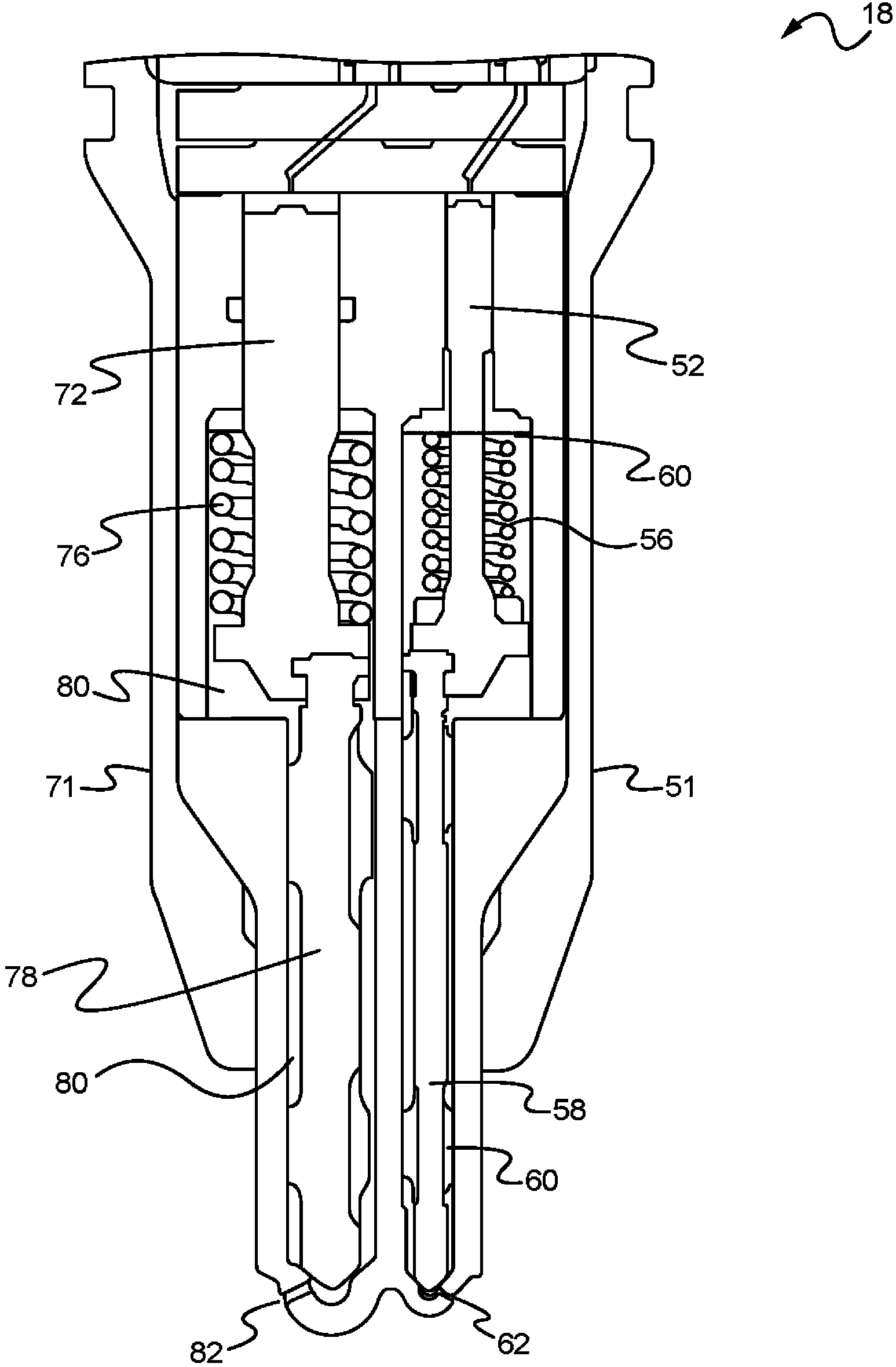

[0016] The present invention provides a system for preventing excess diesel from leaking into the natural gas side of a dual fuel injection system. The system employs a valve that opens and closes in response to pressure from the natural gas line, closing the diesel line when the pressure in the natural gas line drops below a predetermined level.

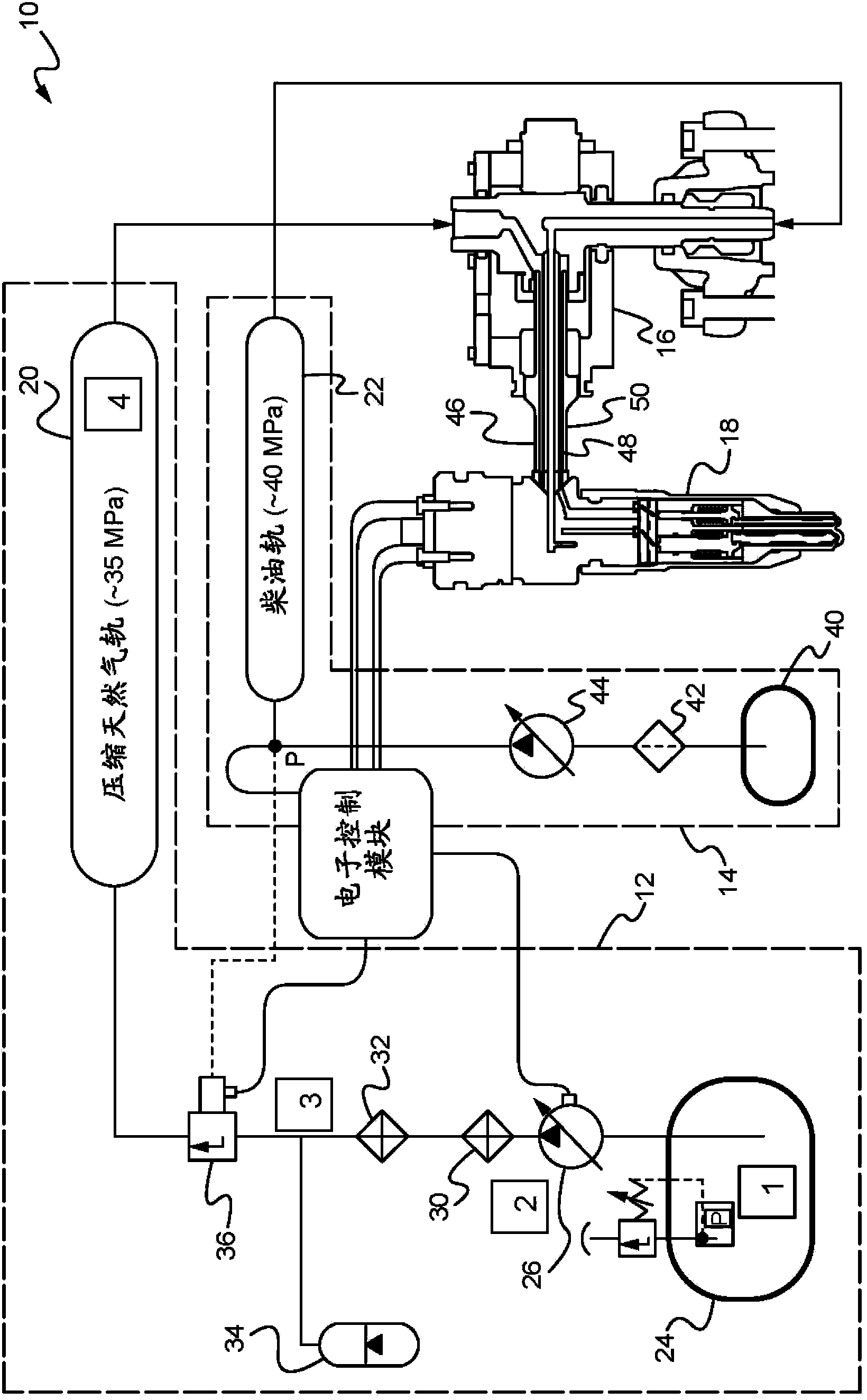

[0017] figure 1 is a schematic diagram of a natural gas and diesel feed system 10 for use in a dual fuel engine. The illustrated system 10 includes a natural gas supply system, generally indicated at 12 , a diesel supply system, generally indicated at 14 , and a plurality of coaxial quill assemblies 16 in fluid communication with a corresponding number of dual fuel injectors 18 . The natural gas supply system 12 and the diesel supply system 14 respectively pass through the natural gas rail 20 and the diesel rail 22 (such as figure 1 shown) supply natural gas (NG) and diesel to the dual fuel injector 18, respectively.

[0018] The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap