Rolling bearing cage, rolling bearing and electric steering system of a motor vehicle

A technology of electric steering system and rolling bearing, which is applied in the field of cage containing balls and ball bearings, can solve the problems of deformation, destruction and damage of the cage, and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

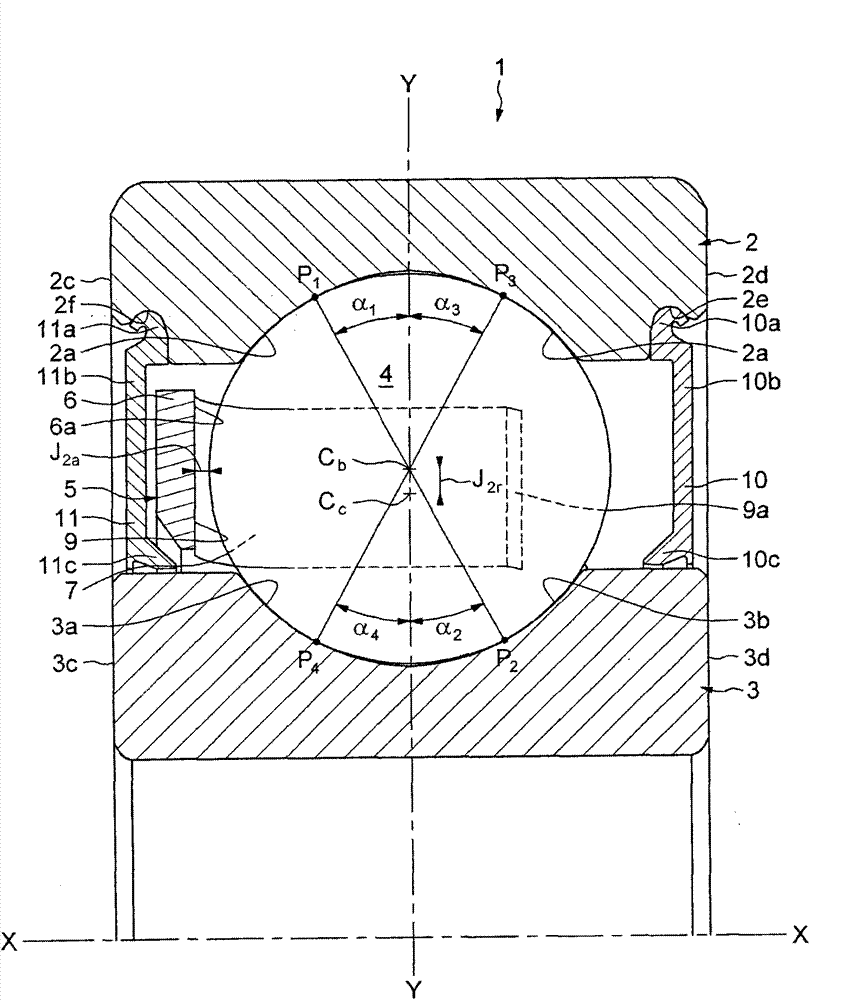

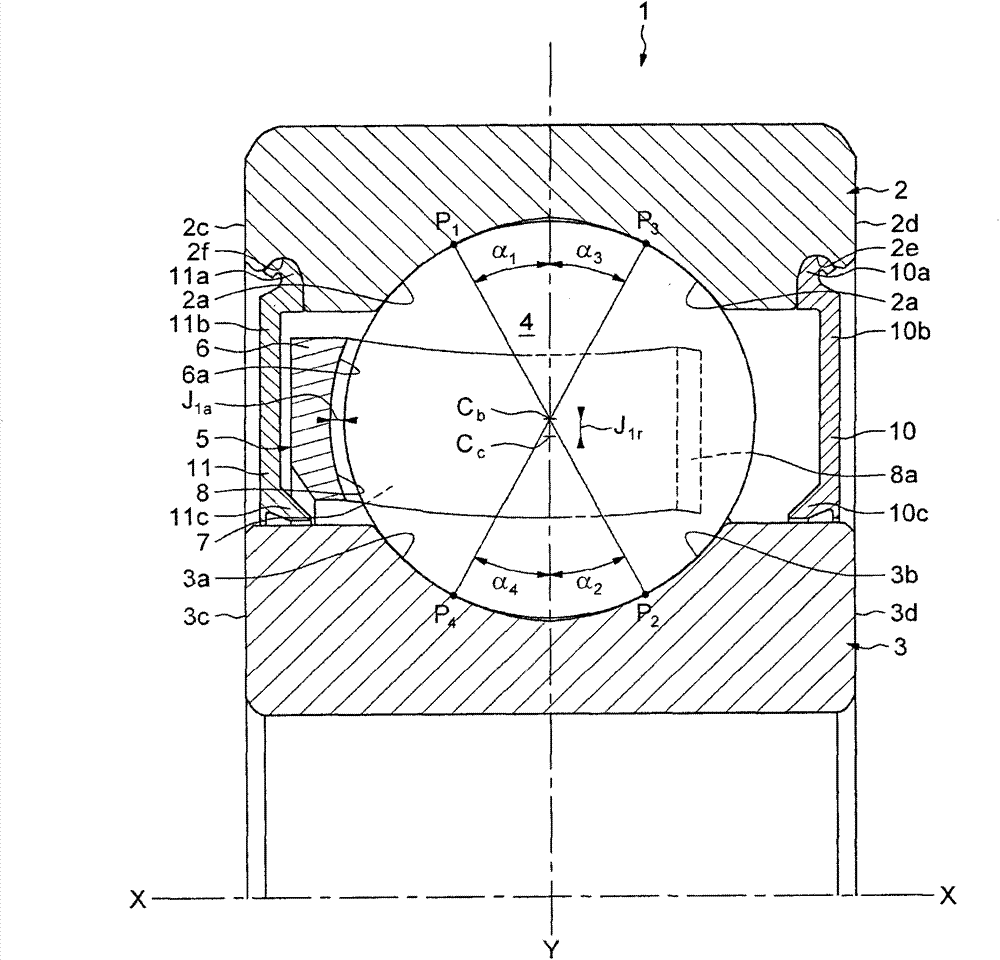

[0026] Rolling bearings, having an axial axis X-X, at Figures 1 to 4 Referenced as a whole in 1, designed to be installed in the steering column of a motor vehicle.

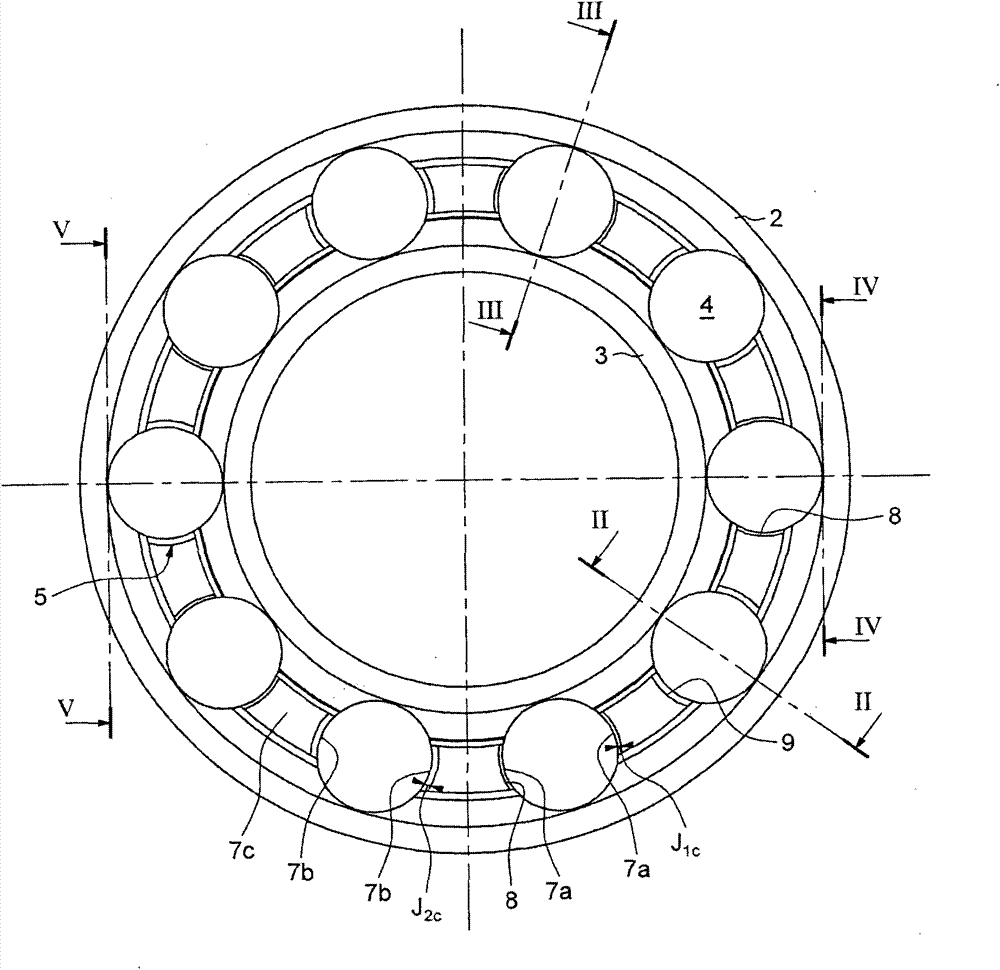

[0027] Such as figure 1 with 2 As shown, a rolling bearing 1 comprises an outer raceway 2 , an inner raceway 3 , a set of rolling elements 4 such as balls and a cage 5 for maintaining a consistent circumferential spacing of the balls 4 .

[0028] The inner raceway 3 is in the form of a generally rectangular sectioned ring of small radial thickness and has two annular bearing tracks 3a, 3b on its outer surface. The outer raceway 2, in a similar manner to the inner raceway 3, comprises two annular bearing tracks 2a, 2b on its inner bore. The inner and outer raceways 3, 2 have substantially in-line front radial surfaces 3b, 3c, 2b, 2c and can each be produced in one piece by machining from one sheet of steel.

[0029] Each ball 4 is in contact with four bearing tracks 2a, 2b, 3a, 3b formed on the inner 3 and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com