A reverse sealing device for a valve stem with a fixed stroke

A reverse seal, stroke valve technology, applied in the direction of the valve device, shaft seal, cock including the cut-off device, etc., can solve the problems of valve stem and bonnet leakage, leakage, short service life, etc., and achieve the effect of reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

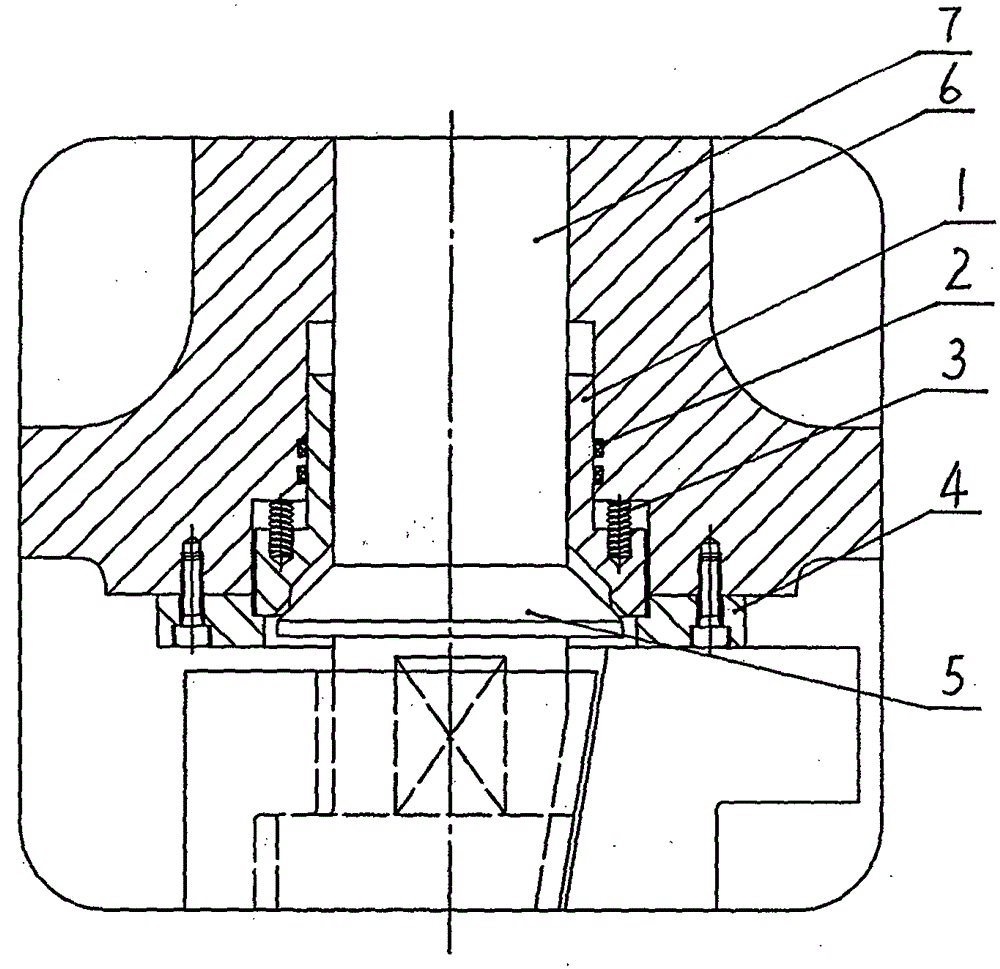

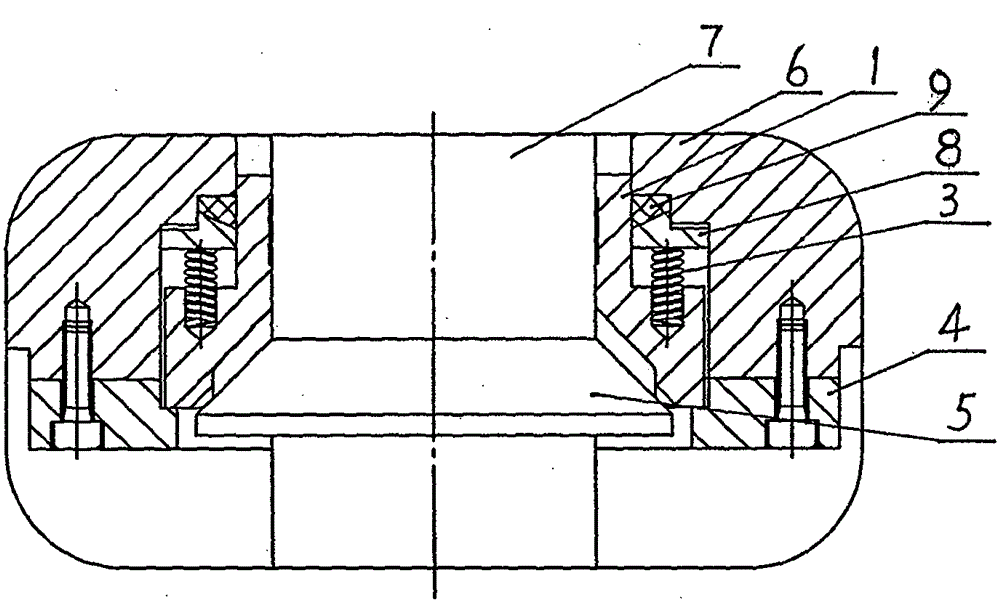

[0010] Such as figure 1 The reverse sealing device of the fixed-stroke valve stem shown includes a valve cover 6 and a valve rod 7, and a reverse sealing device is provided in the middle cavity between the valve cover 6 and the valve rod 7, and the reverse sealing device consists of an upper sealing seat 1, The pre-tightening spring 3 and the lower baffle 4 are composed. The upper sealing seat 1 is composed of two parts: the upper small-diameter outer cylinder and the lower large-diameter outer cylinder. That is, the upper sealing seat 1 is composed of two cylinders with different outer diameters. The upper cylinder The outer diameter of the cylinder is smaller than the outer diameter of the lower cylinder. The outer cylindrical surfaces of the small-diameter outer cylinder and the large-diameter outer cylinder respectively cooperate with the small round hole and the inner wall of the large round hole in the valve cover 6 for dynamic sealing, and the pre-tension spring 3 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com