Pipe assembly for the flow of a fluid and of a current and method for assembling such a pipe assembly

A technology of fluid flow and tube assembly, applied in the direction of fluid heaters, pipes/pipe joints/fittings, hoses, etc., can solve the problems of power consumption, low efficiency, heat loss, etc., and achieve low cost and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

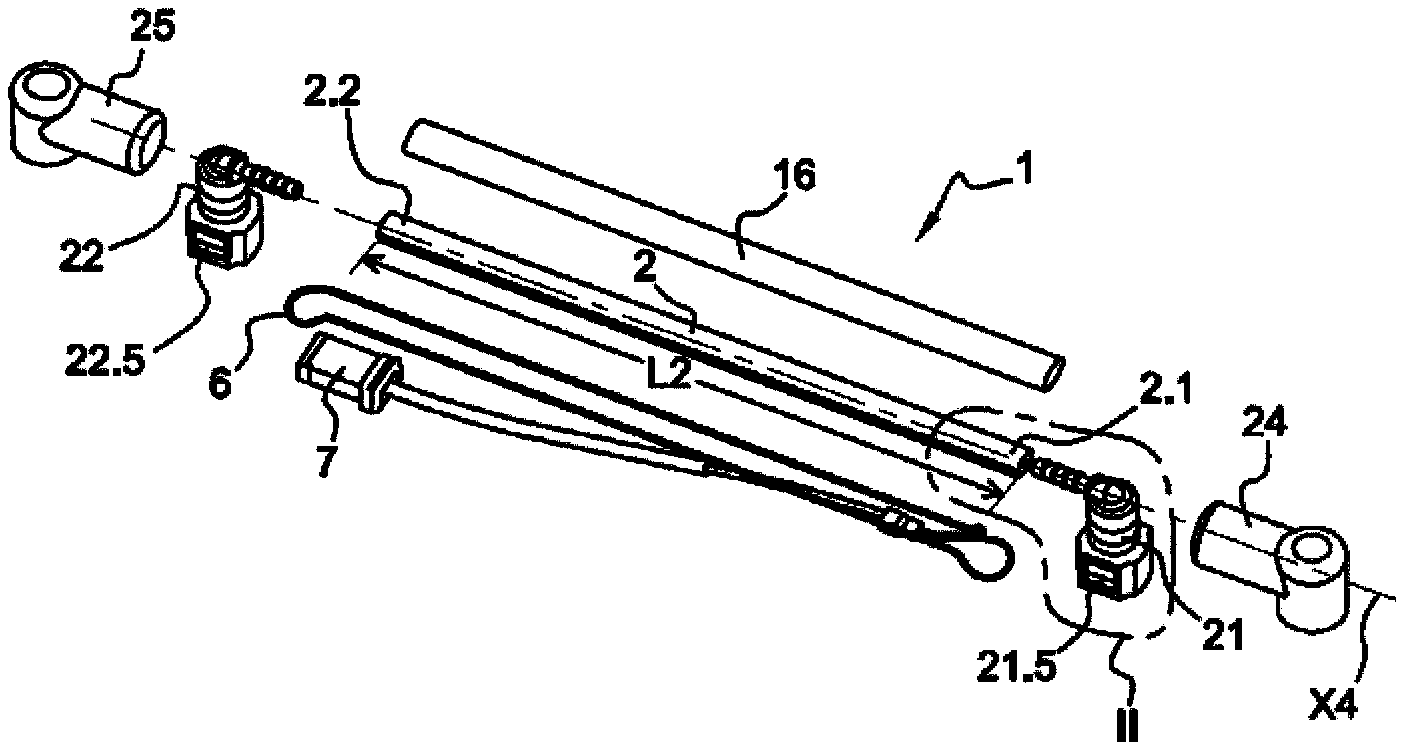

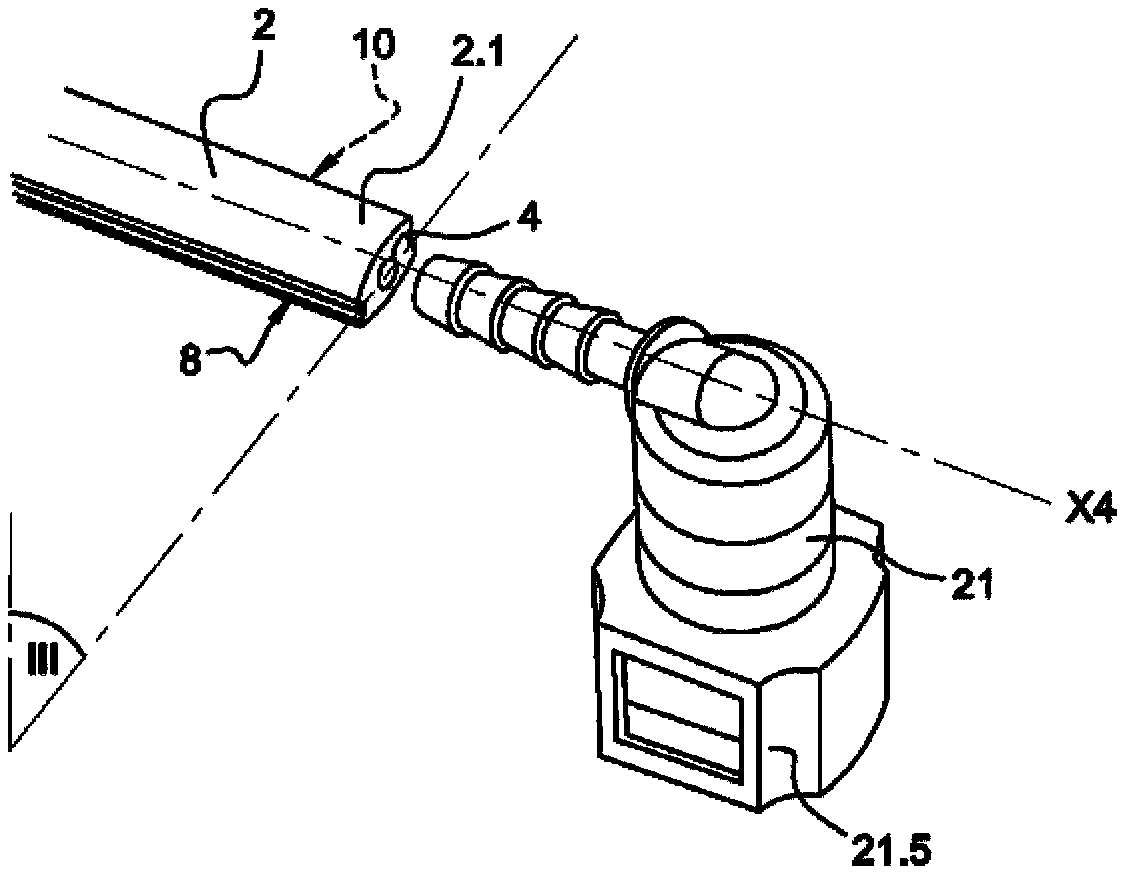

[0069] figure 1 with figure 2 Shown is a tube assembly 1 for fluid flow and electrical current circulation along a tube 2 . In the illustrated example, the fluid is a liquid consisting of an aqueous urea solution, and the electric current has the function of heating the aqueous urea solution as it flows inside the pipe 2 .

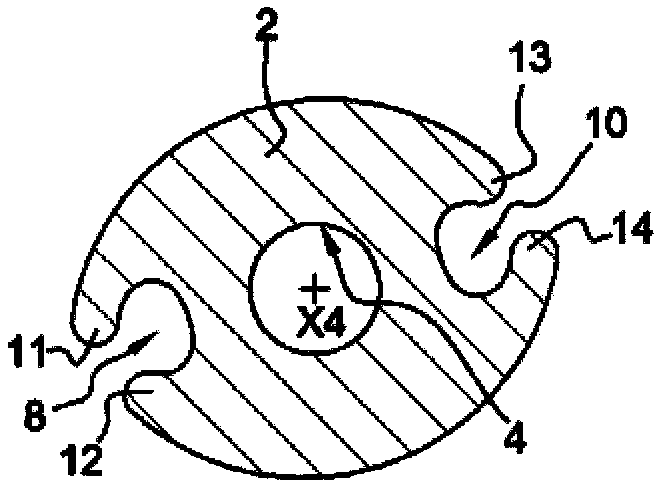

[0070] The tube assembly 1 comprises a tube 2 having an inner conduit 4, such as figure 2 shown. The inner conduit 4 is configured for liquid flow. To this end, the inner conductor 4 leads to the first end 2.1 of the tube 2 and to the second end 2.2 of the tube 2 .

[0071] The tube assembly 1 also includes a wire 6 which is an electrical conductor and has a length greater than that of the tube 2 . The wire 6 is here formed by a resistive wire suitable for converting electric current into heat by means of the Joule effect. The wire 6 here consists of a metallic material. The resistivity of the wire 6 is determined according to the application of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com