Microtome having a piezoelectric linear actuator

一种压电致动器、切片机的技术,应用在仪器、科学仪器、取样等方向,能够解决小步进、高间隔和重量要求、不允许样品架切割单元快速运动等问题,达到高速移动、高分辨率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

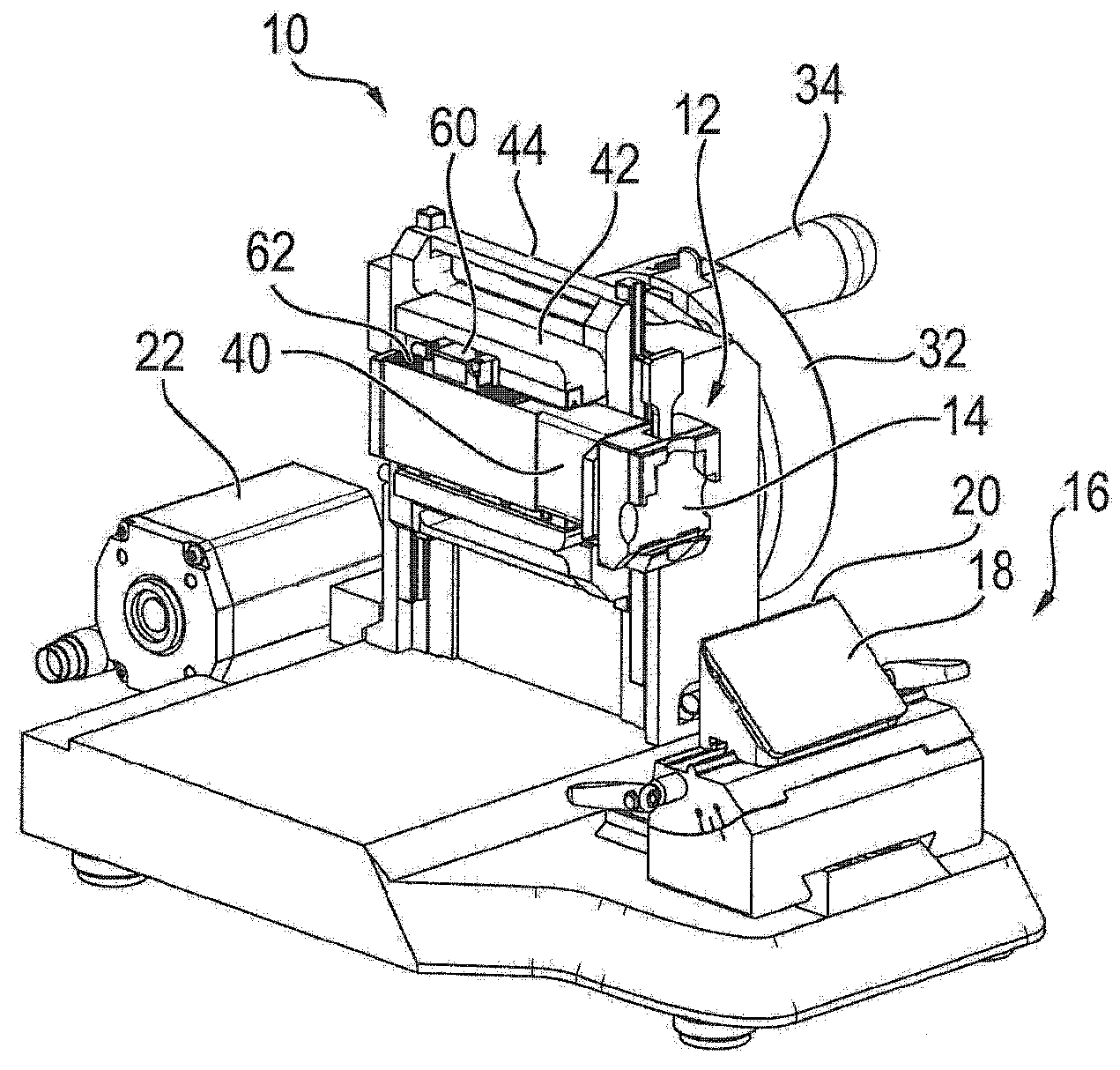

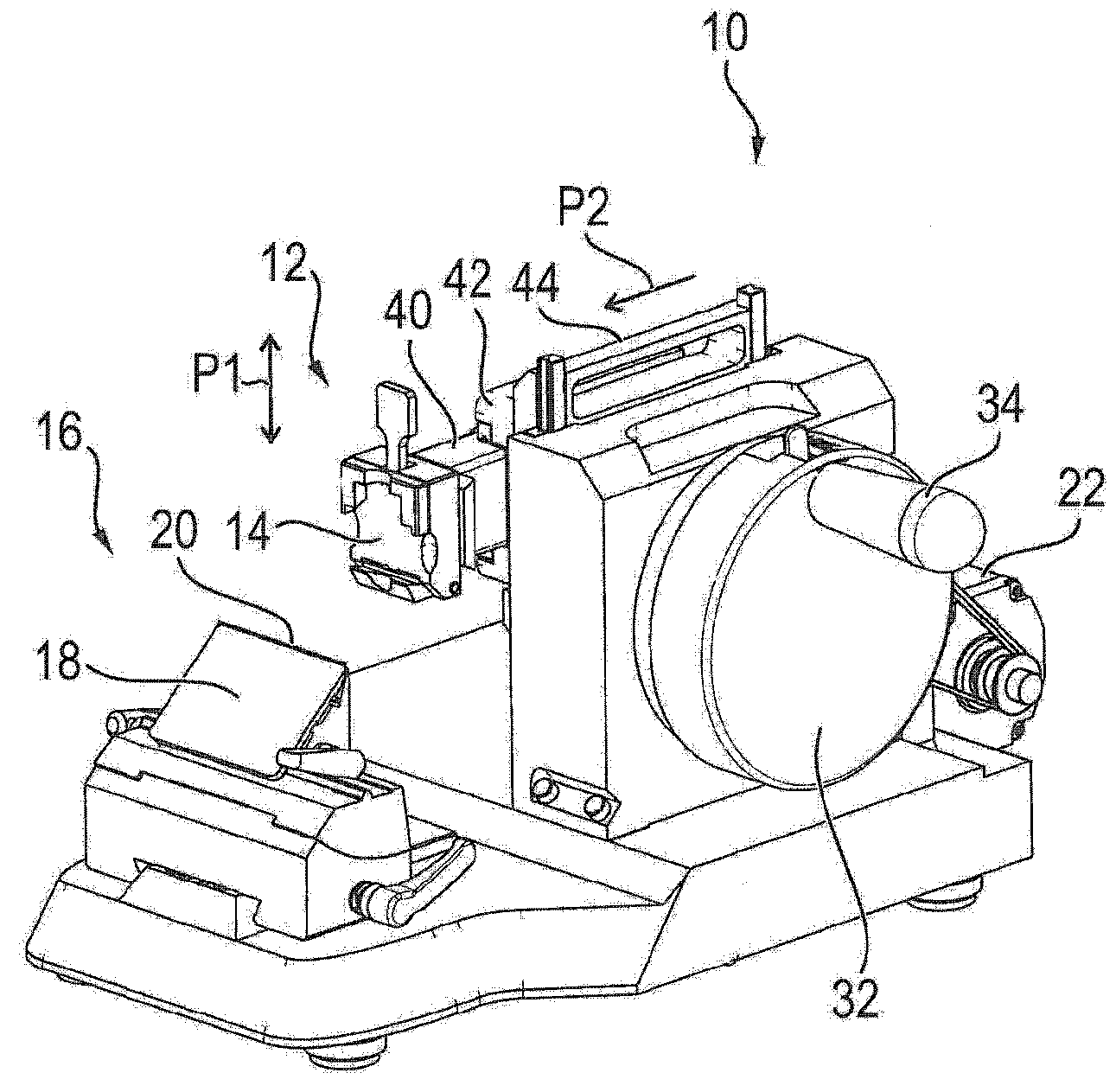

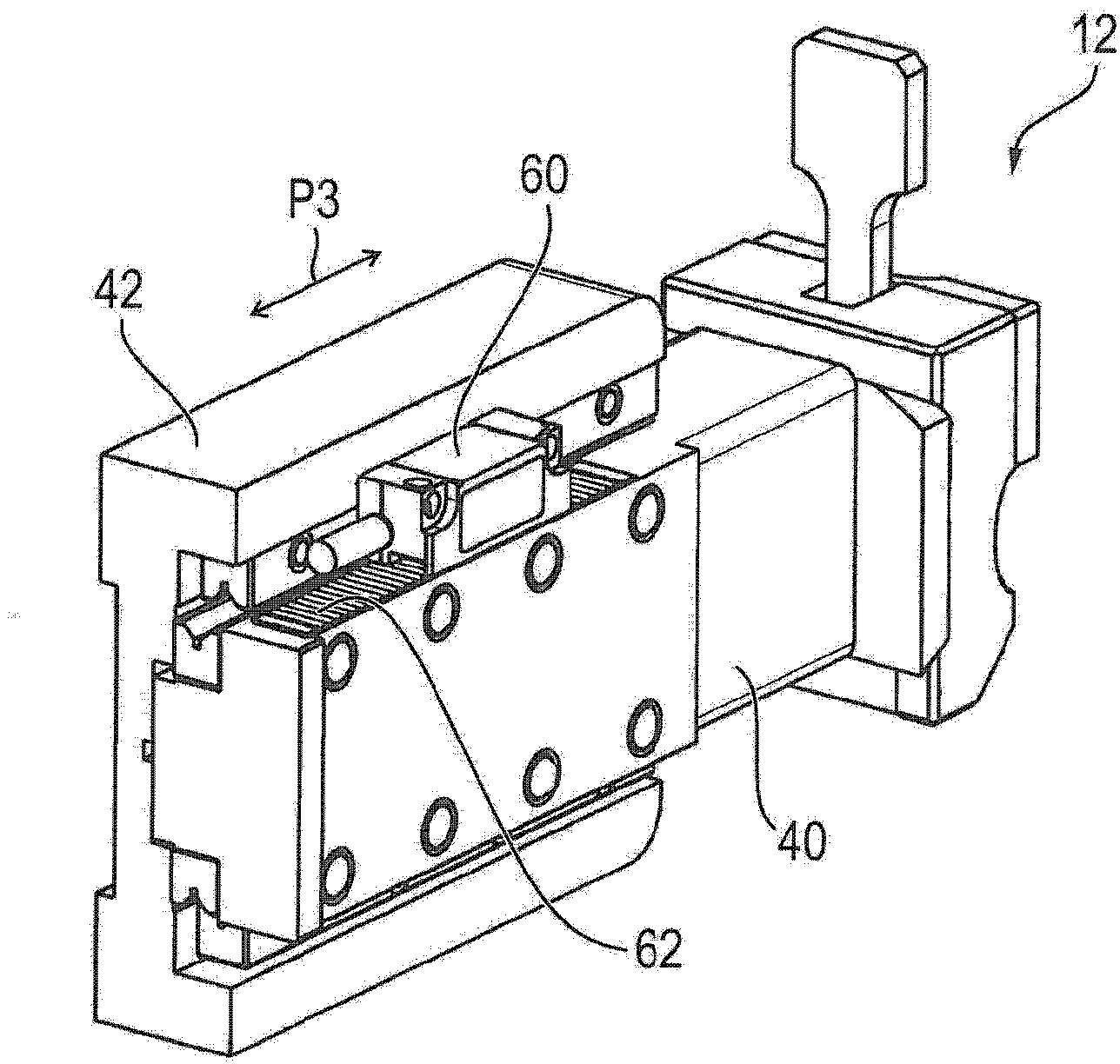

[0035] figure 1 with figure 2 Each is a schematic perspective view depicting the microtome 10 in a very simplified form, showing only the components necessary for the invention. For example, the case has been omitted to see the internals.

[0036] Microtome 10 includes a sample holder 12 that includes a chuck 14 for holding a sample to be sectioned. The microtome 10 also has a cutting unit 16 comprising a blade holder 18 and a blade 20 clamped in the blade holder 18 for cutting the sample.

[0037] Furthermore, the microtome 10 includes a hand wheel 32 with a handle 34 . The rotational movement of the handwheel 32 is detected by a rotary encoder (not shown). The control unit (also not shown) controls the driving unit 22 according to the detected rotational movement of the hand wheel 32, so that the sample holder 12 moves back and forth relative to the stationary cutting unit 16 in the direction indicated by the double arrow P1, thereby passing through the blade 20 The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com