Device for detecting flue gas in flue

A flue and flue gas technology, used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of measurement time lag, complicated gas sampling and preprocessing operations, and deviation of measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

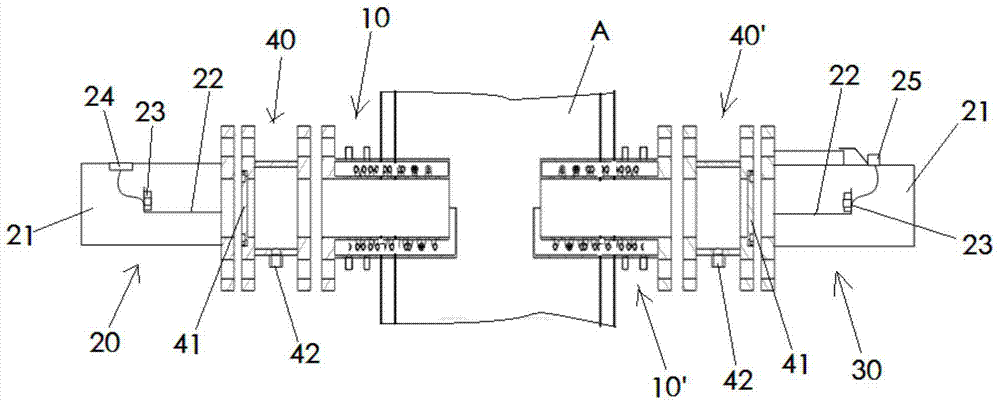

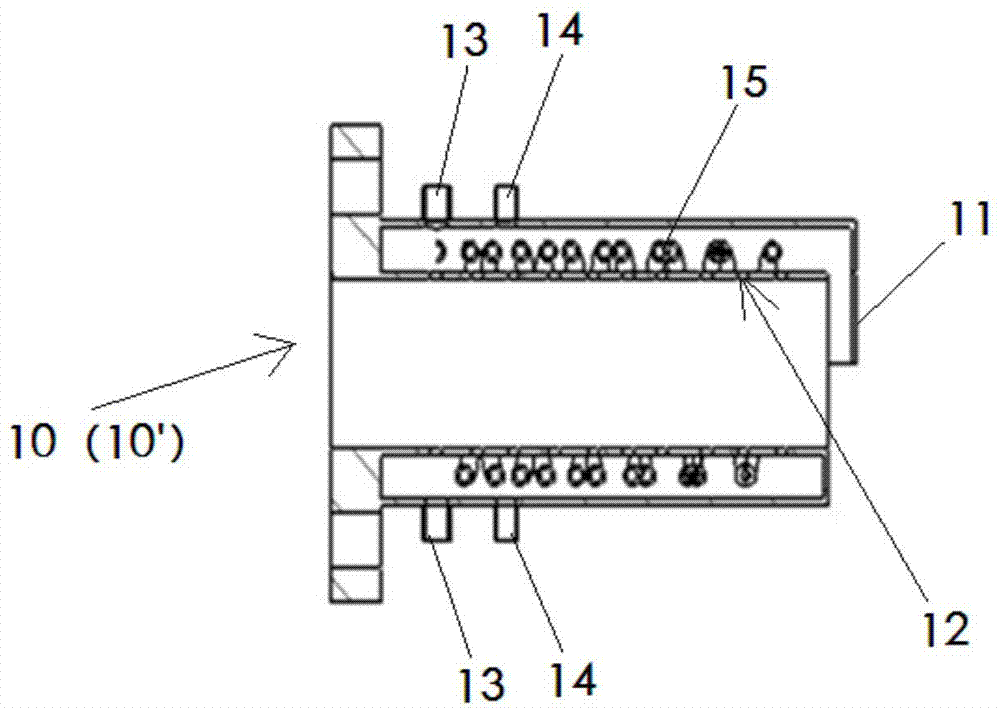

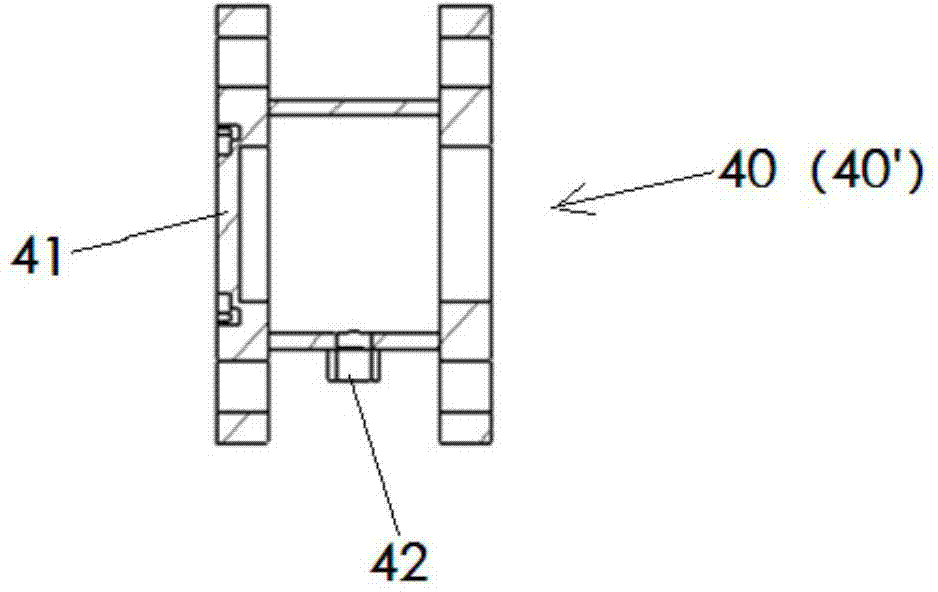

[0009] The present invention will be further described below through specific implementation methods. The flue gas temperature in different flue A varies greatly. For the flue gas with lower temperature, the main purpose is to prevent dust from affecting the laser projection. Therefore, the scheme that the present invention takes is as figure 1 As shown, a device for detecting smoke in the flue, which includes the first and second pipe bodies 10 and 10' respectively arranged on the side walls of the flue A corresponding to both sides, the first and second pipe bodies 10, 10' are arranged along the same beam path, which crosses the flow path of the flue gas in the flue A, and the first and second pipes 10, 10' are arranged on the periphery of the flue A respectively. A light-transmitting sheet 41 that separates the inner cavity of the first and second tube bodies 10, 10' from the external environment. The outer sides of the two light-transmitting sheets 41 are respectively prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com