Method for manufacturing low-reflectivity pattern sapphire substrate

A sapphire substrate and graphic substrate technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of lack of international competitiveness, insufficient research and development of high-end products, and monopoly of high-end markets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0025] The key of the present invention is to prepare the sapphire pattern substrate by combining dry and wet etching, select appropriate ICP etching conditions to form periodic patterning on the sapphire surface, and effectively reduce the direct reflection of light. After the material is grown, the loss of light in the material can be effectively reduced, and the extraction efficiency and output rate of light can be improved to improve the luminous efficiency of the chip.

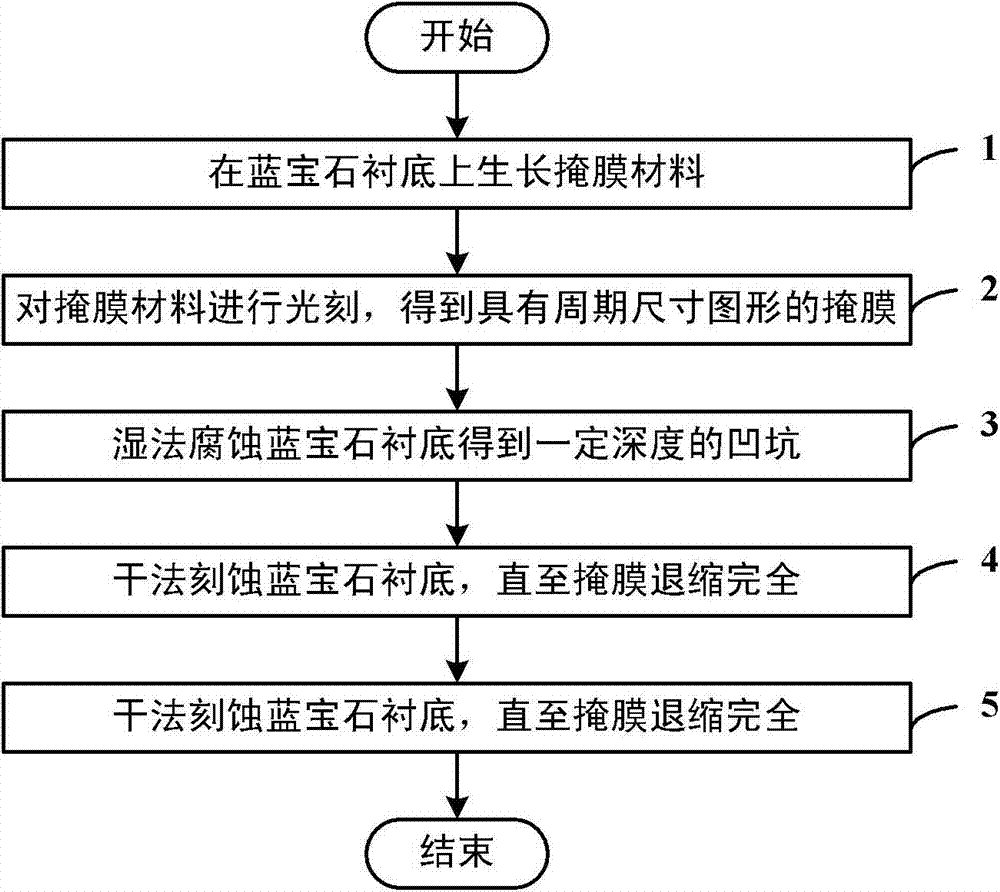

[0026] Such as figure 1 as shown, figure 1 It is a flow chart of a method for preparing a low-reflectivity sapphire pattern substrate provided by the present invention, the method comprising:

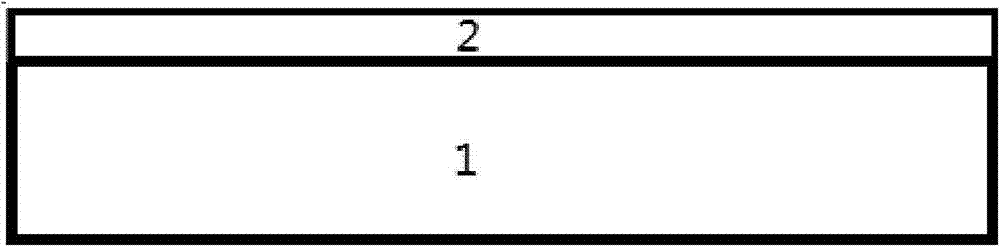

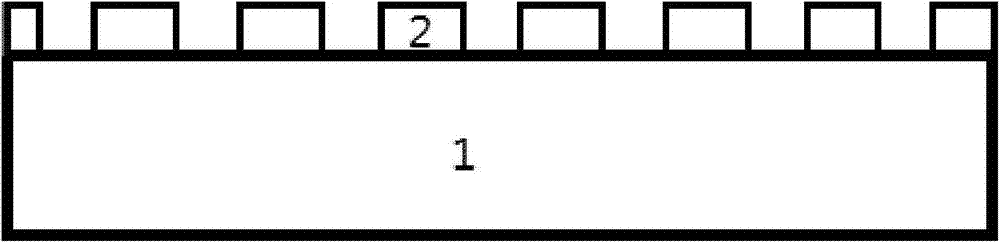

[0027] Step 1: growing a mask material on a sapphire s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com