Ball-head wire clamping device for tightening overhead lines

A technology of overhead lines and clamping device, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as low work efficiency, poor safety of transmission line wire tightness, and easy drop of single-string porcelain bottles, so as to improve work efficiency and ensure construction The effect of safety and improving the efficiency of line tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

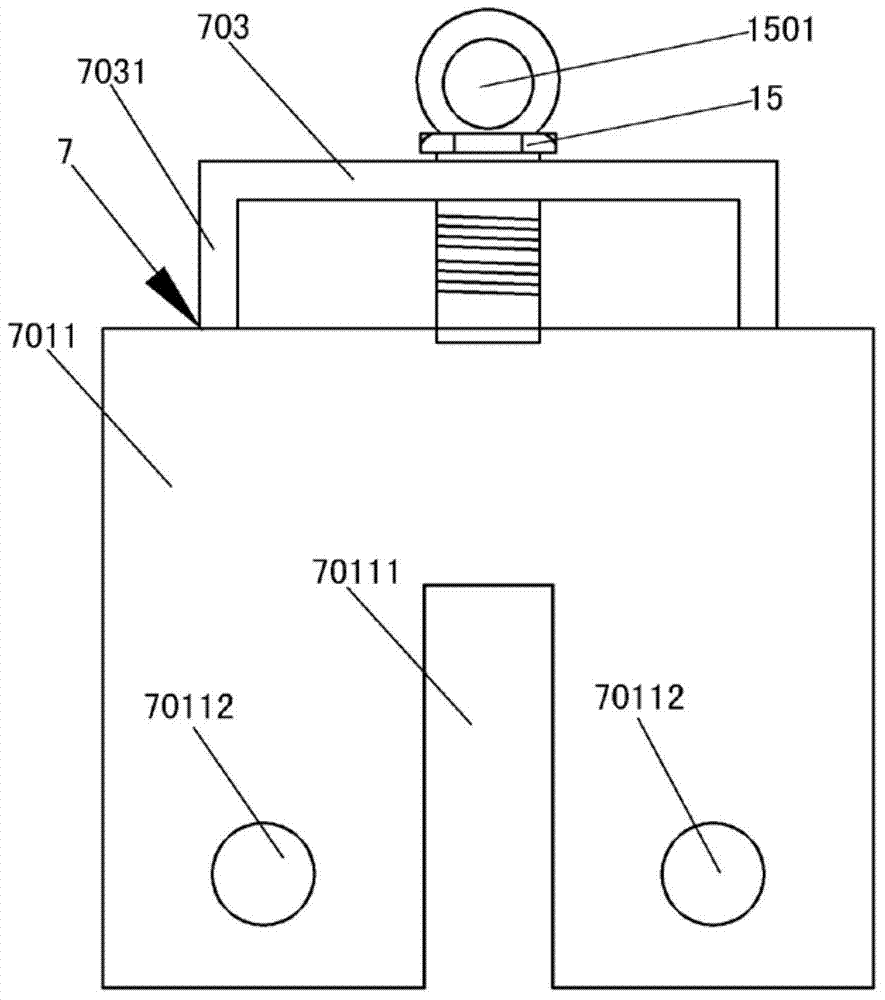

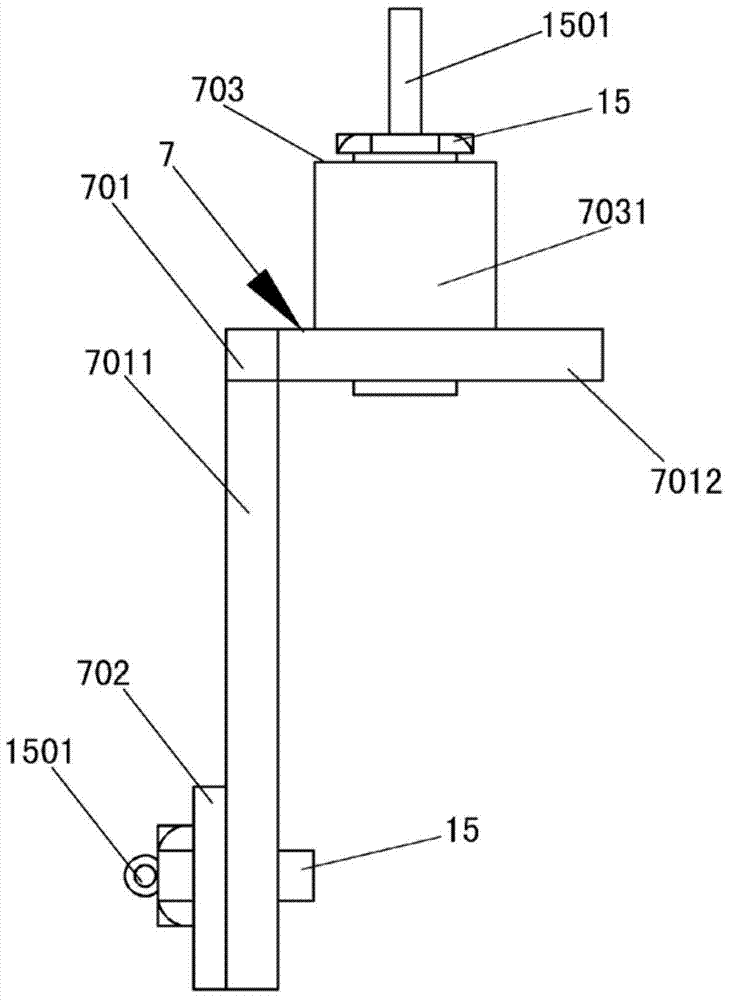

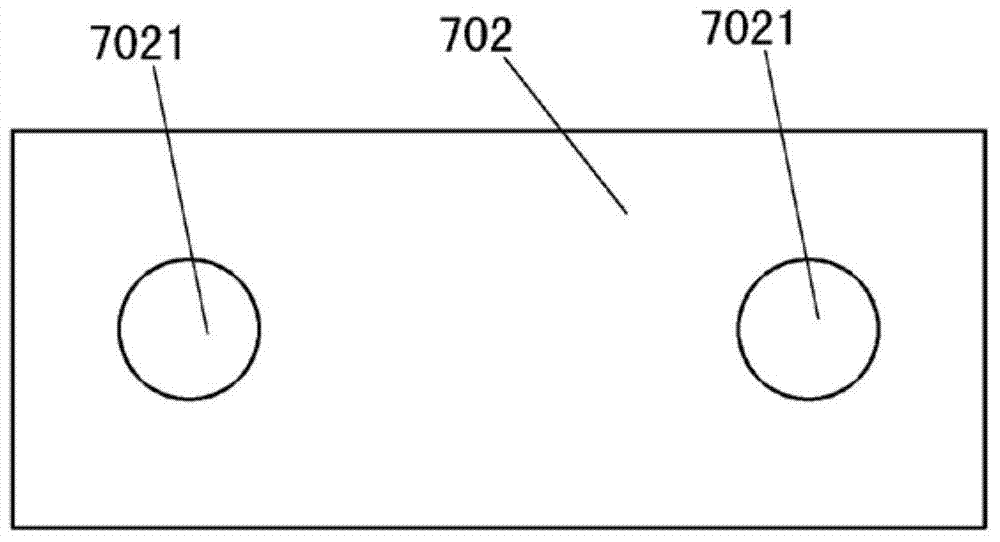

[0029] see Figure 1 to Figure 10 , the ball clamp 7 used for overhead line tightening includes an L-shaped plate 701, a square plate 702, three screws 15 with a pull ring 1501 and a top plate 703, and the L-shaped plate 701 includes a first A straight plate 7011 and a second straight plate 7012 fixedly connected to the first straight plate 7011; one end of the first straight plate 7011 away from the second straight plate 7012 is provided with a The thickness direction runs through the rectangular opening groove 70111 of the first straight plate 7011; on the first straight plate 7011, a first screw hole 70112 is opened on both sides of the rectangular opening groove 70111; on the square plate 702 There are two fourth through holes 7021;

[0030] The top board 703 is fixedly arranged on the board surface of the second straight board 7012 away from the first straight board 7011, and the top board 703 is provided with a The second screw hole of the top plate 703; the second str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com