Powder hopper for feeding pigs

A technology of powder and hopper, which is applied in the field of powder hopper for feeding pigs, can solve the problems that feed cannot flow in smoothly, feed is easily blocked in the outlet of the hopper, and affects normal feeding, etc., and achieves a simple structure, low cost, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

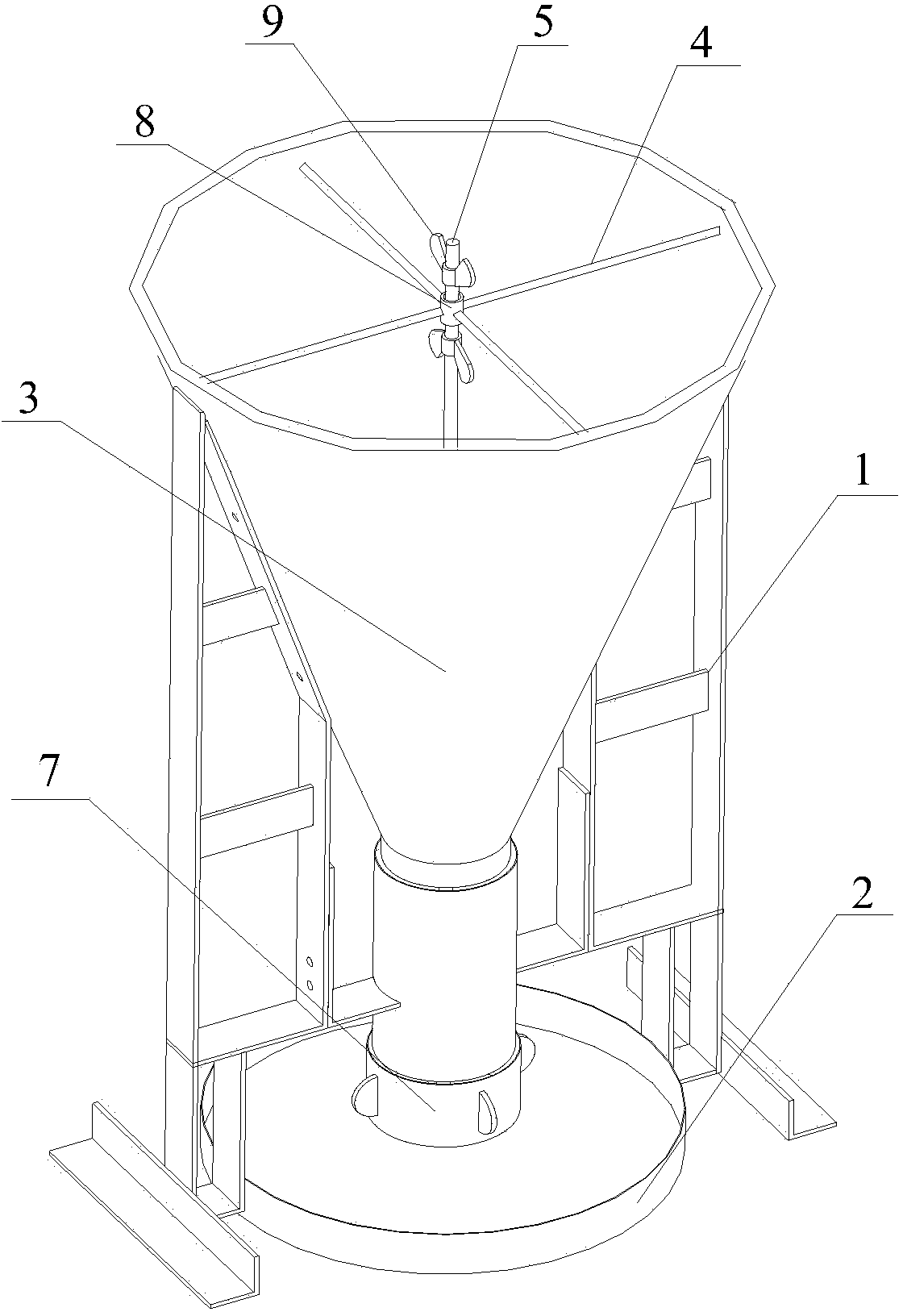

[0028] Such as figure 1 , 2 As shown, the powder hopper of the present invention is mainly composed of a support base 1 , a feeding pan 2 and a silo 3 . The supporting base 1 is made of metal and is used to support the feeding pan 2 and the silo 3 , and the feeding pan 2 and the silo 3 are both arranged on the supporting base 1 . Both the feeding pan 2 and the silo 3 are made of stainless steel, and the feeding pan 2 and the silo 3 are welded on the support base 1, so that the support base 1, the feeding pan 2 and the silo 3 are arranged integrated structure. The feed bin 3 is used to store feed, and the breeder can fill the feed bin 3 with feed at one time, and feed the pigs for several days without adding feed every time. The feeding pan 2 is located below the feed bin 3. When feeding, the feed in the feed bin 3 flows into the feeding pan 3 through the discharge port at the bottom of the feed bin 3 to be eaten by pigs.

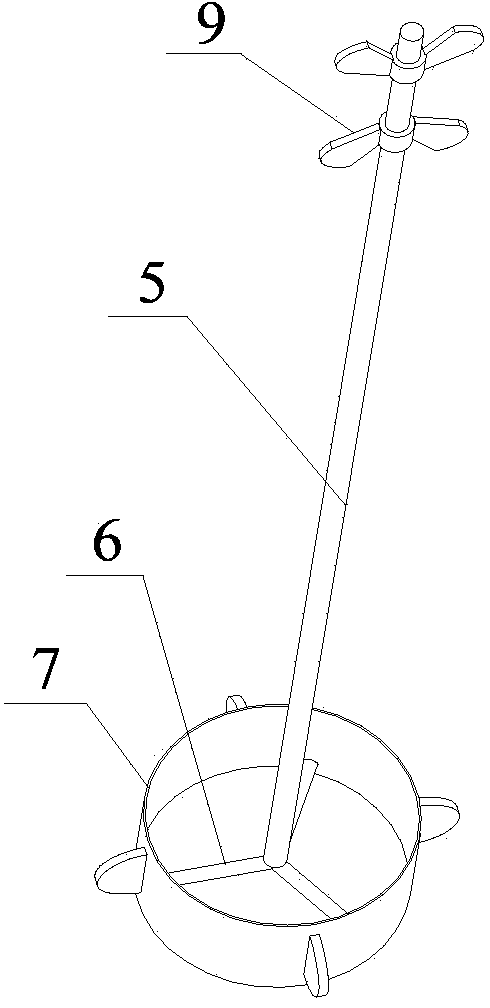

[0029] In order to prevent the agglomerated feed f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap