Pond auto-clean cage culture facility

An automatic net cage cleaning technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of reducing fish production in ponds, limiting the length of cages, increasing the incidence of disease, etc., achieving reduced oxygen consumption in ponds, simple management, The effect of short runtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

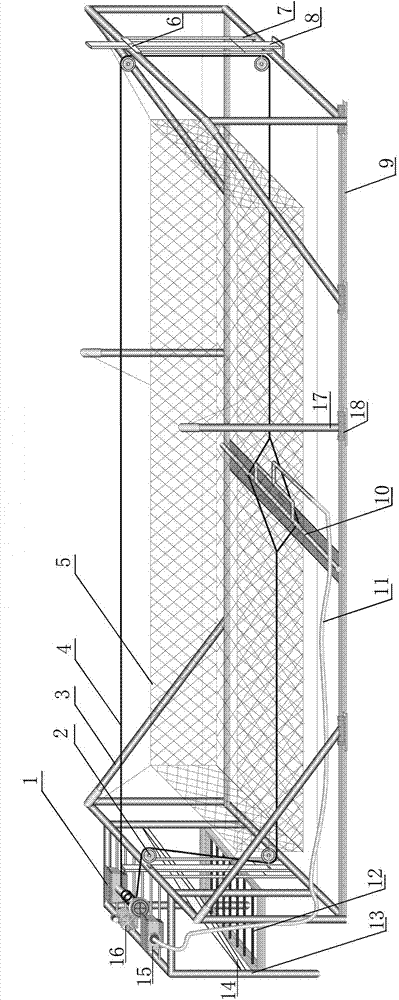

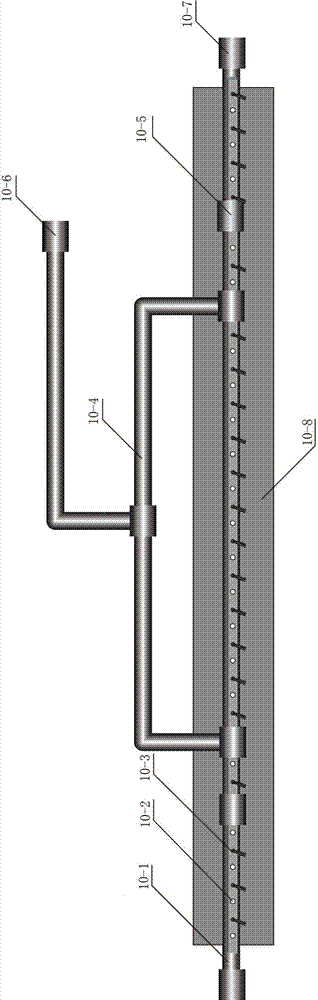

[0020] The present invention comprises net cage frame, blower fan 16, sewage suction pump 15, sewage suction pipe 10, stay rope 4, rope roller and power drive part 1, and net cage frame is made up of two angular frames 3, a rectangular frame 13, two The angular frames 3 are respectively located on both sides of the pond, and the rectangular frame 13 is connected to one of the angular frames. The sewage suction pump 15, the blower fan 16, the rope roller and the power drive part 1 are installed on the rectangular frame 13, and two Sewage suction pipe slide rail 9, a fixed pulley 2 is installed at the midpoint of the upper cross bar of the angle frame 3, two positioning bars 7 are installed on the angle frame 3, a pulley positioning bar 8 is installed between the two positioning bars 7, and the upper end has A locking ring 6 for locking the pulley positioning rod 8, a fixed pulley 2 is installed at the lower end of the pulley positioning rod 8, and the pull rope 4 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com