Copper-clad plate glass cloth gluing apparatus

A cloth coating and copper-clad laminate technology, which is applied in the field of glass cloth coating devices for copper-clad laminates, can solve problems such as no space for installation, and achieve the effects of guaranteed quality, good implementation effect, and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The content of the present invention will be described below in conjunction with specific embodiments.

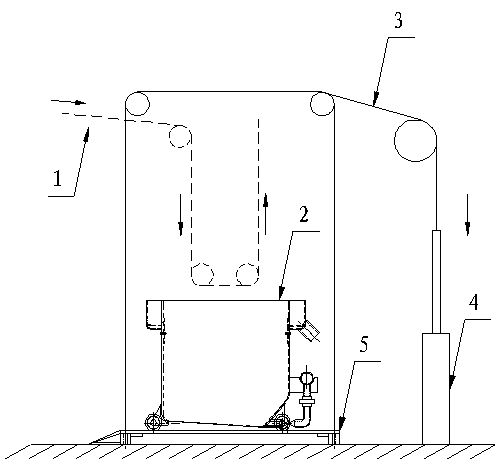

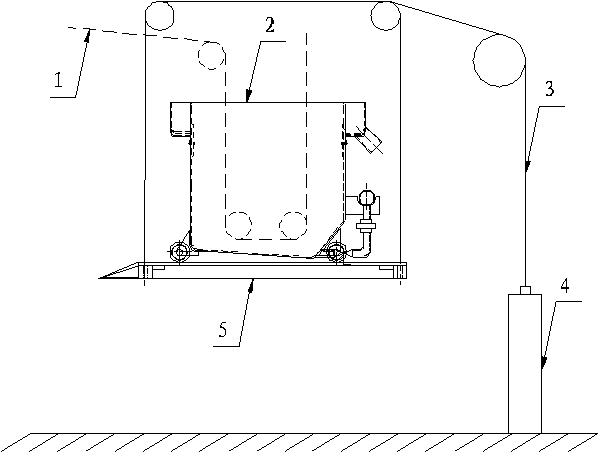

[0013] Such as figure 1 Shown is the structural representation of the gluing device of the present invention, figure 2 Schematic diagram of its working structure. The gluing device is for uniform gluing of the glass cloth 1 , and the gluing device includes a main dipping tank 2 , a chain 3 , a cylinder 4 and a lifting frame 5 . The main dipping tank 2 is set directly under the glass cloth 1, the main dipping tank 2 is set on the lifting frame 5, the lifting frame 5 is directly placed on the ground, one end of the chain 3 is connected to the lifting frame 5, and the other end is connected to the cylinder 4, when the cylinder 4 When working, the chain 3 pulls the lifting frame 5 upwards, drives the main dipping tank 2 to move upwards, and finally dips the glass cloth 1 in the main dipping tank 2. Since the lifting frame 5 is placed on the ground, the height between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com