Machining center

A machining center and mounting rod technology, which is applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem that the machining center is difficult to apply to mass production, and achieve the effect of improving processing efficiency and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

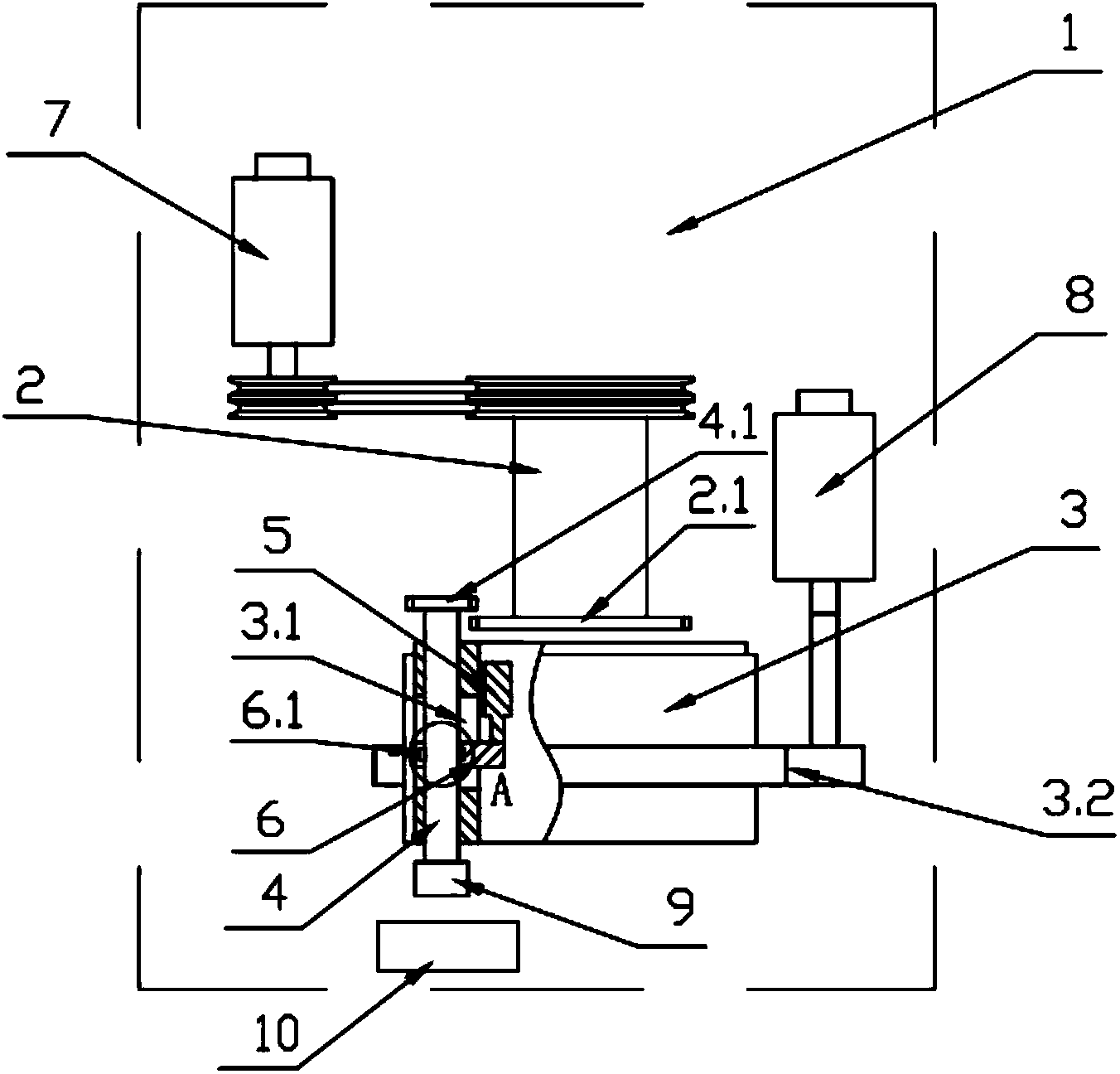

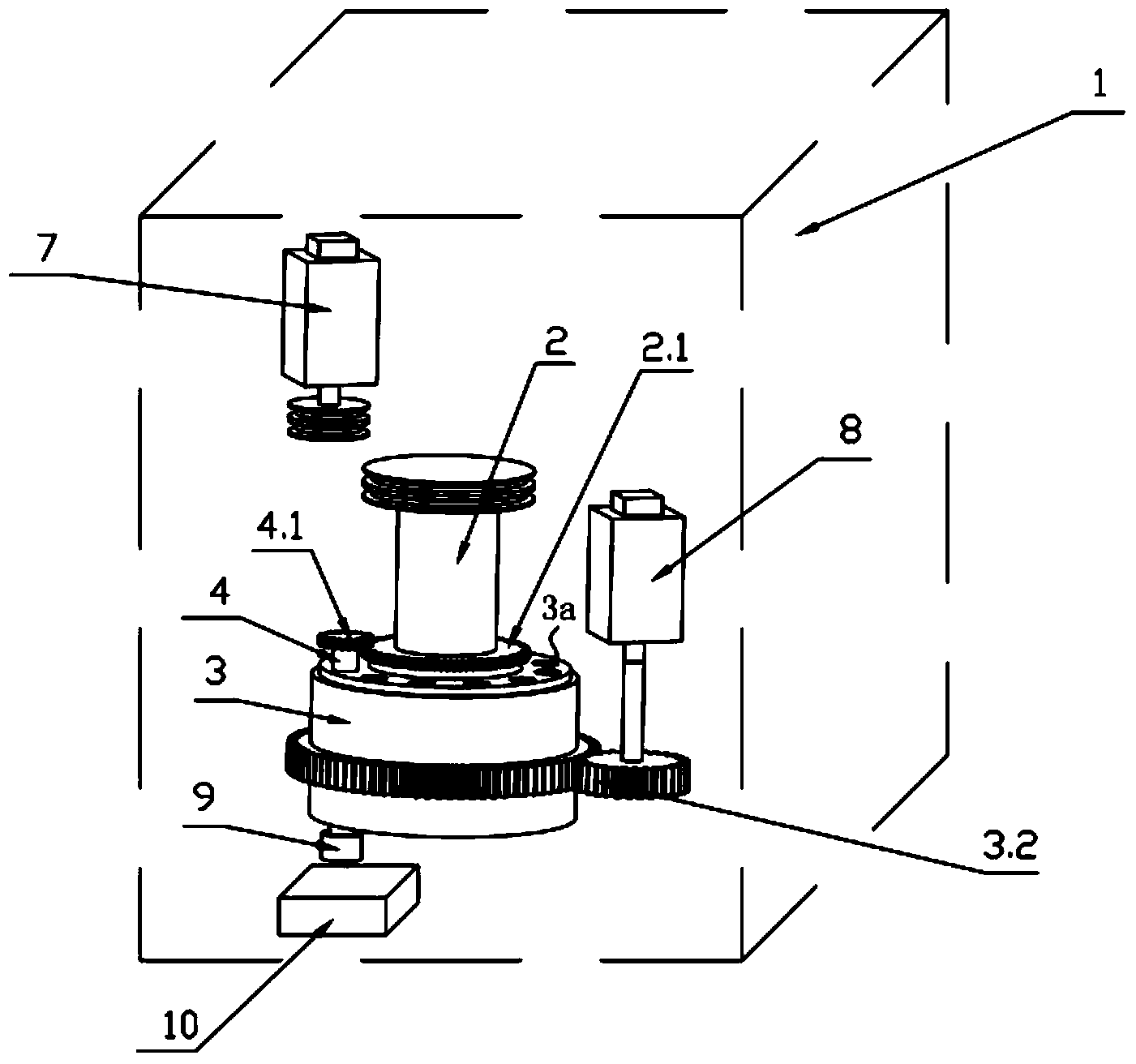

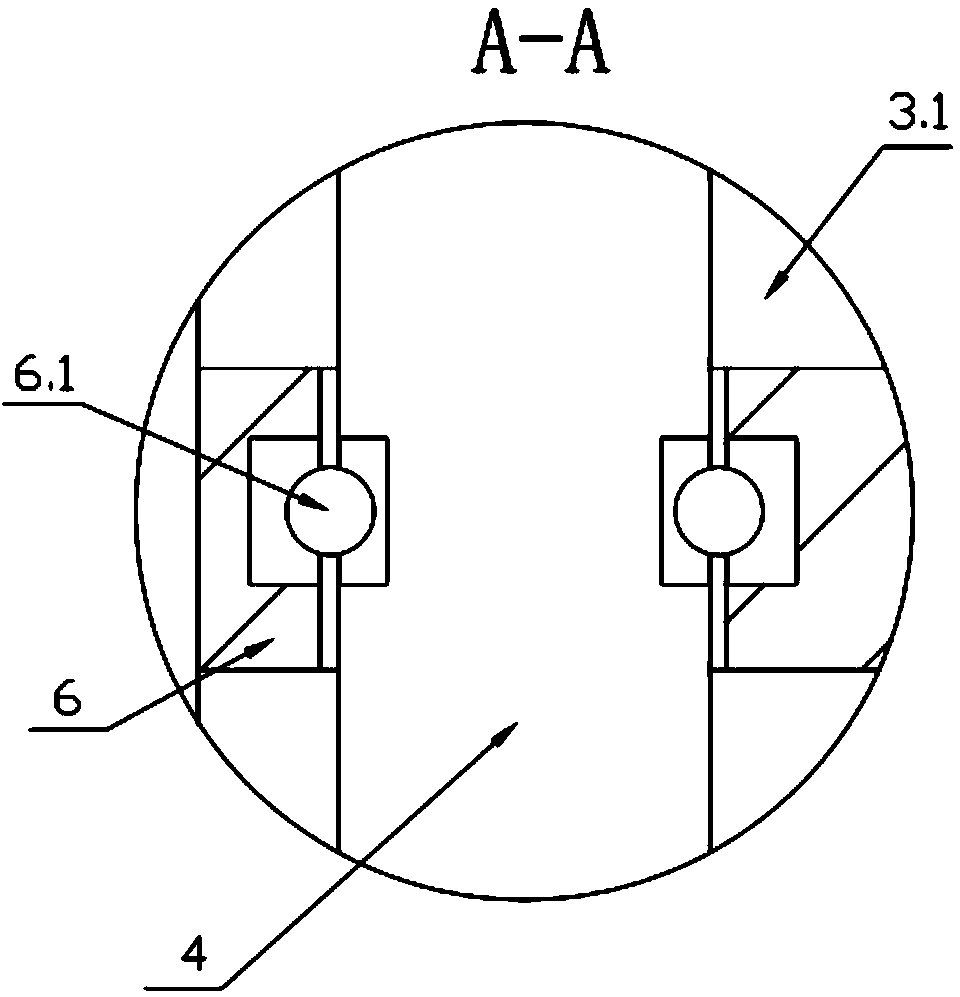

[0019] like figure 1 As shown, the machining center of the present invention includes a main body 1, a driving shaft 2 arranged on the main body 1 and driven to rotate by a first motor 7, and a tool magazine 3 driven to rotate by a second motor 8. The first The motor 7 and the second motor 8 are both electrically connected to the control unit, that is, the start and stop of the first motor 7 and the second motor 8 are automatically controlled through the control panel of the machining center. The axis of the tool magazine 3 is perpendicular to the upper surface of the workpiece 10 to be processed. The tool magazine 3 is provided with through holes of the same circle and evenly distributed for accommodating the mounting rods 4 of different tools 9. The mounting rods 4 slides and rotates to fit in the through hole, and the bottom end of each insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com