Vehicle front axle machining system and machining method

A processing system and pre-car technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of inability to process workpieces, limited load capacity of A rotating bearing, limited workpiece size and weight, etc. Fast knife, improved clamping and transfer efficiency, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Embodiment 1, front axle processing system

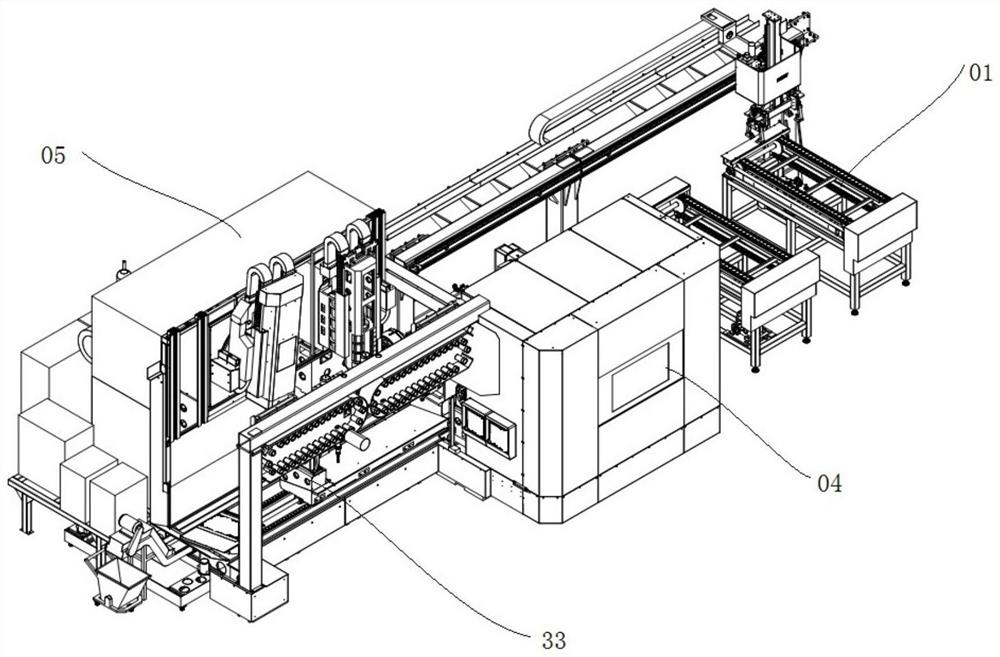

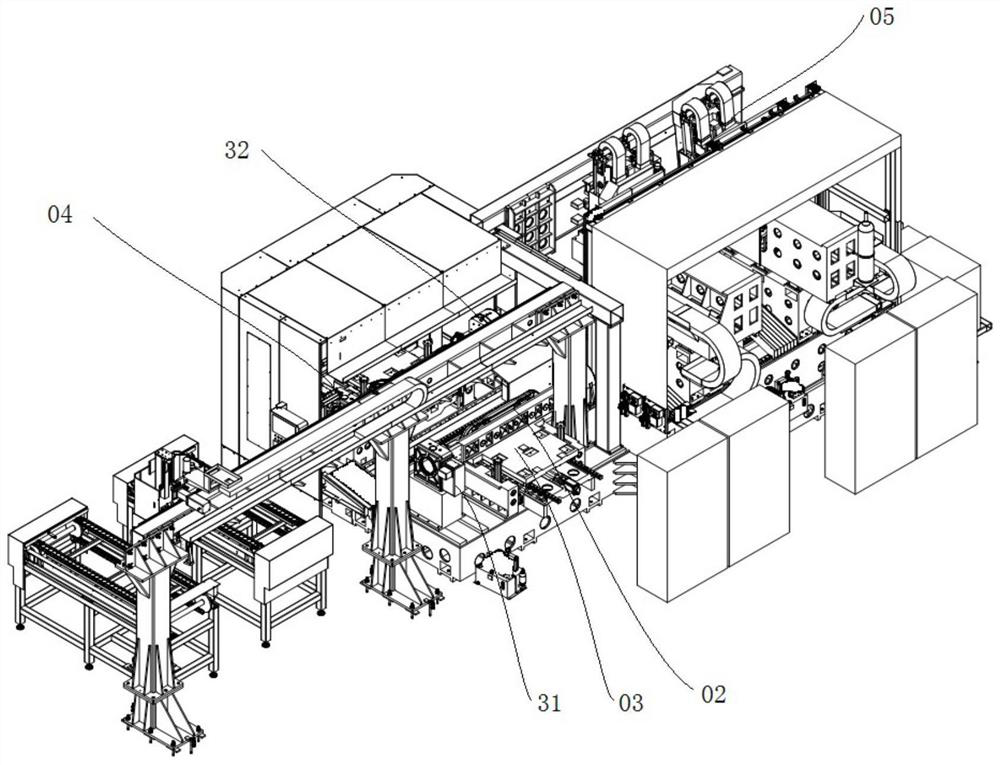

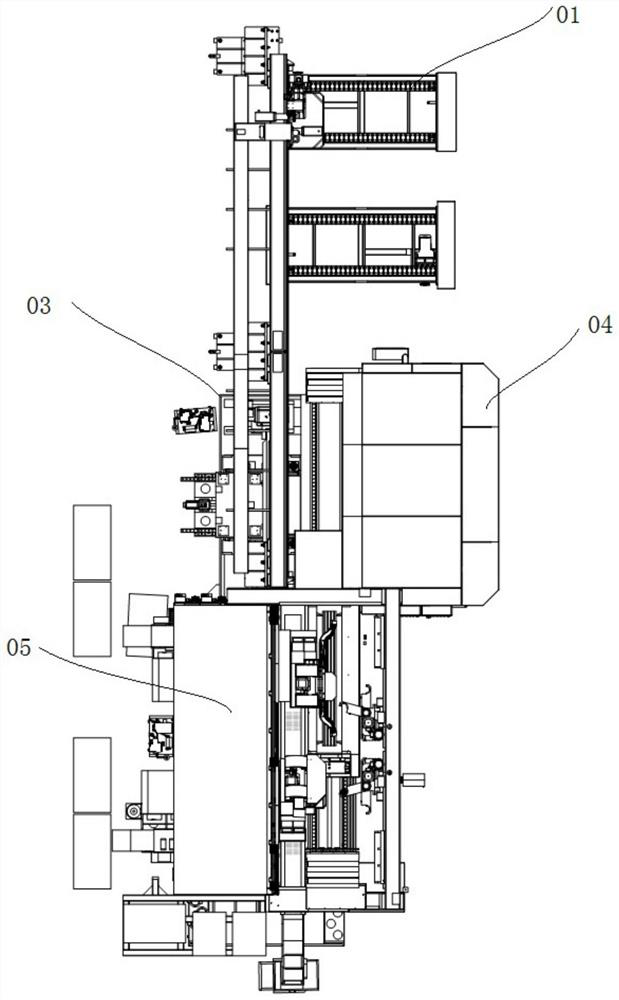

[0110] The invention provides a front axle processing system that completes processes including loading, positioning, and drilling, such as Figure 1 ~ Figure 3 As shown, it includes a feeding device 01, a clamping device 02, a transfer exchange platform 03, a detection and positioning device 04 and a processing machine tool 05. The transfer transfer platform 03 includes a detection and positioning device respectively arranged under the feeding device 01. The three sets below 04 and at the processing machine tool 05 are respectively the first conversion platform 31 , the second conversion platform 32 and the third conversion platform 33 . The feeding device 01 transfers the front axle 06 to be processed to the position of the clamping device 02. After clamping, the transfer and exchange platform 03 transfers the workpiece to the detection and positioning device 04 for detection and positioning, and then the transfer and excha...

Embodiment 2

[0182] Embodiment 2, front axle processing method

[0183] Adopt the front axle processing system described in embodiment 1, comprise the steps:

[0184] Step 1, feeding, using a feeding device to transfer the front axle to be processed to the clamping device of the first conversion platform;

[0185] Step 2, using the clamping device to clamp and fix the front axle;

[0186] Step 3. The clamping device and the front axle to be processed are transferred from the first conversion platform to the second conversion platform, and are detected and positioned at the detection and positioning device, and the size of the front axle to be processed is recorded;

[0187] Step 4. After detection and positioning, the front axle to be processed is transferred from the second conversion platform to the third conversion platform, and transferred to the processing machine tool along the base of the conversion platform for machining.

[0188] Preferably, in step 3, on the first conversion pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com