IGBT module electrode bending locating tool, equipment and using method

A technology for positioning tooling and electrodes, applied to workpiece clamping devices, manufacturing tools, etc., can solve problems affecting work efficiency, difficulty in ensuring positioning and orientation accuracy, etc., achieve stable positioning, improve bending quality and bending efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention discloses a module positioning tool for stabilizing the positional relationship between the IGBT module bottom plate and the bending equipment by adopting a method of assuming a positioning pin in the through hole of the module bottom plate.

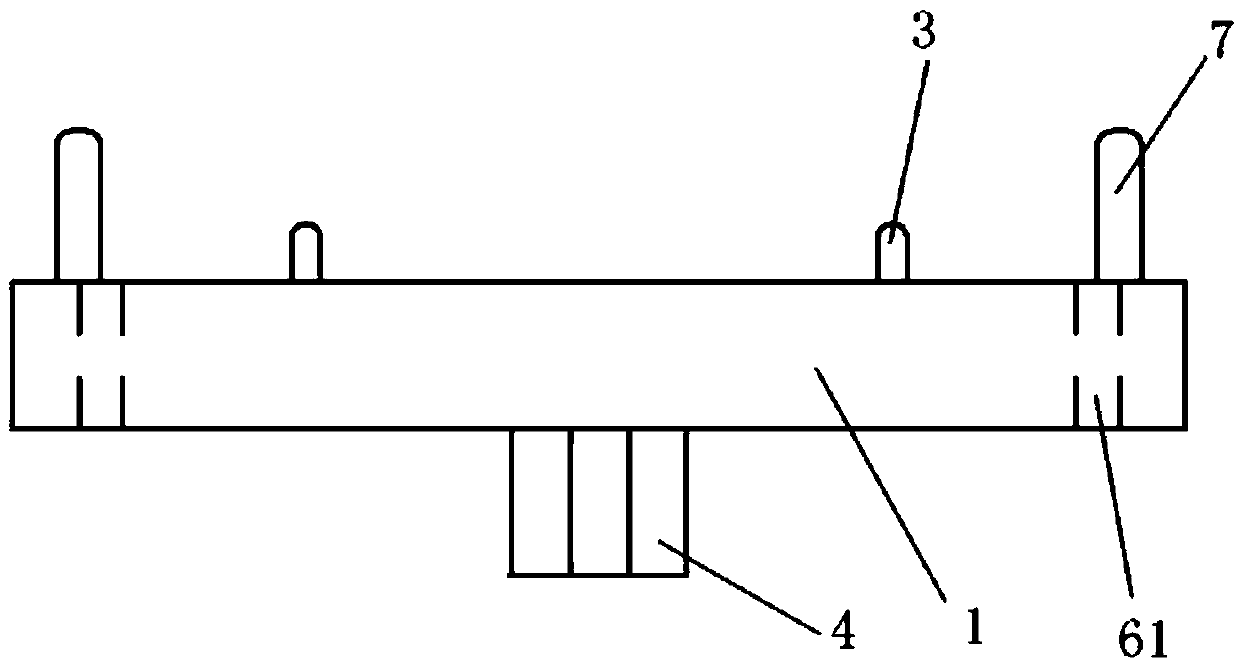

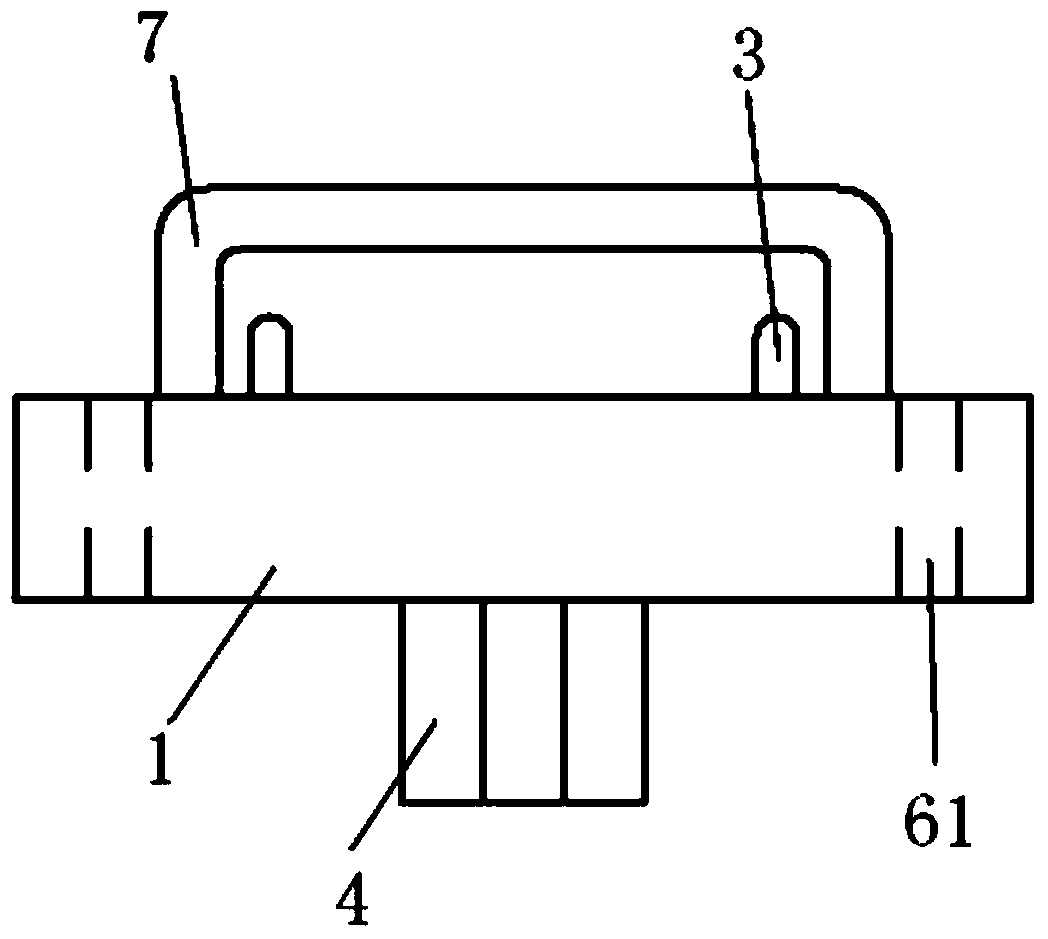

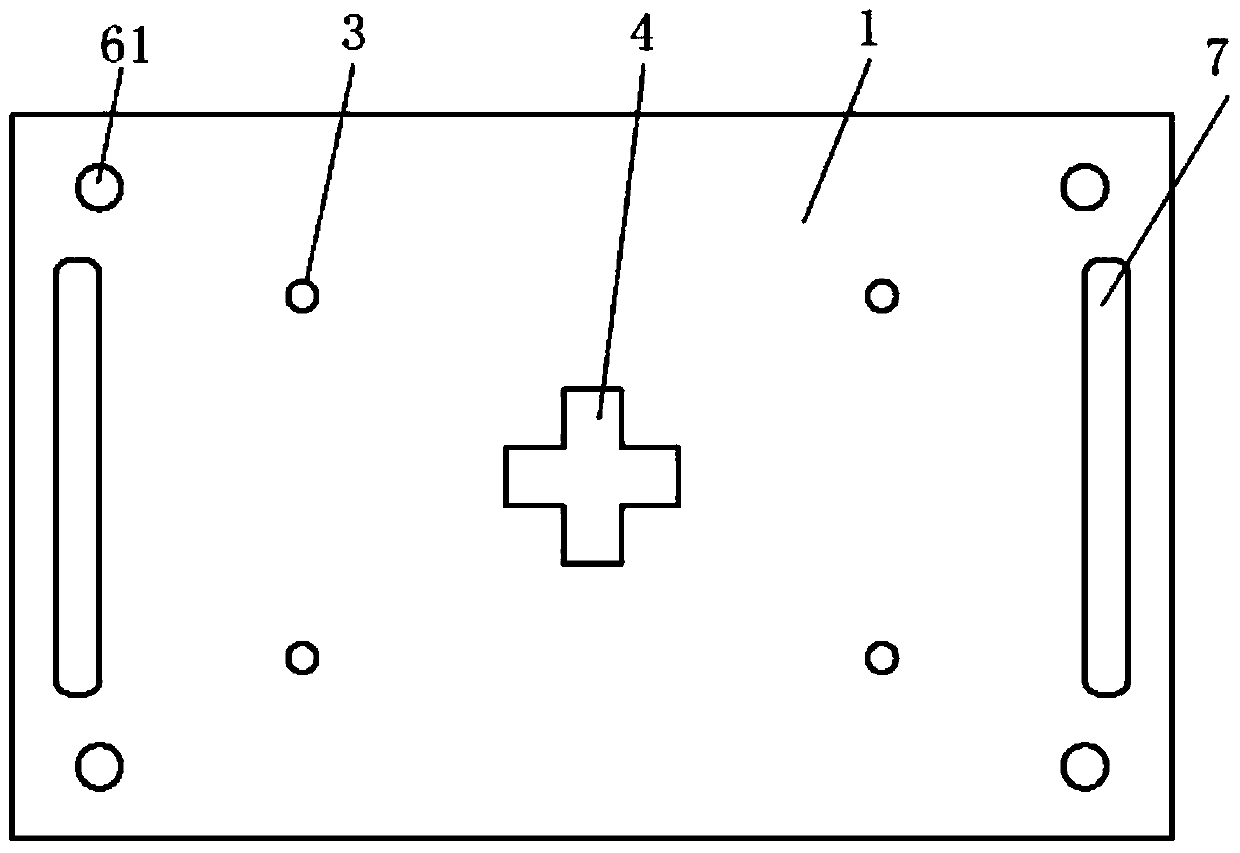

[0031] Such as Figure 1 to Figure 4 As shown, the module positioning tool in the embodiment of the present invention includes a positioning chassis 1 and a bending equipment base 2 . The positioning chassis 1 is used to support and fix the bottom plate of the IGBT module. The edges of the IGBT module bottom plate are provided with a number of installation through holes. The positioning chassis 1 is provided with four mounting holes at the positions corresponding to the four corners of the IGBT module. A positioning pin 3, the shape, position and size of the positioning pin 3 must be made in strict accordance with the shape, position and size of the installation through hole at the bottom of the IGBT module bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com