A method for preventing scuffing after double-zero aluminum foil annealing

A double-zero aluminum foil and annealing technology is applied in the field of preventing aluminum foil from cracking after annealing and double-zero aluminum foil annealing to prevent cracking. It can solve the problems of irregular temperature changes throughout the aluminum coil, internal stress that cannot be released, and internal stress concentration. The overall quality is improved, the effect is excellent, and the effect of market expansion

Active Publication Date: 2016-04-20

JIANGSU DAYA ALUMINUM

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] The purpose of the present invention is to provide a method for preventing double-zero aluminum foil from cracking after annealing, so as to solve the problem that the temperature of the whole body of the aluminum coil changes irregularly during the heating and cooling process of the aluminum coil during the annealing process. Leading to the defect of the aluminum coil from the surface to the inside

Method used

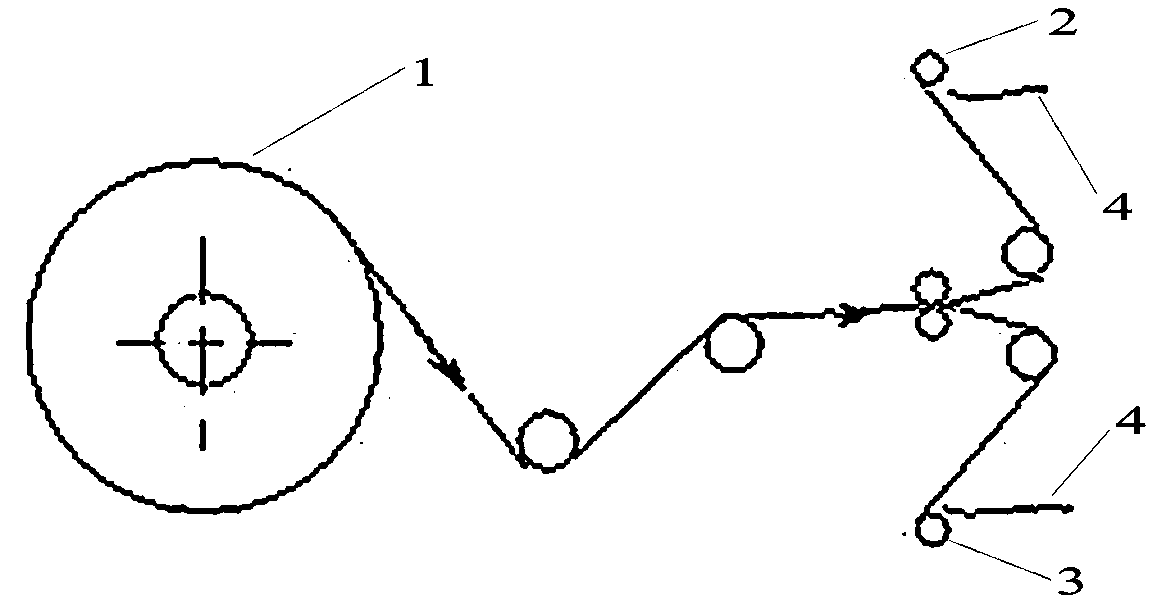

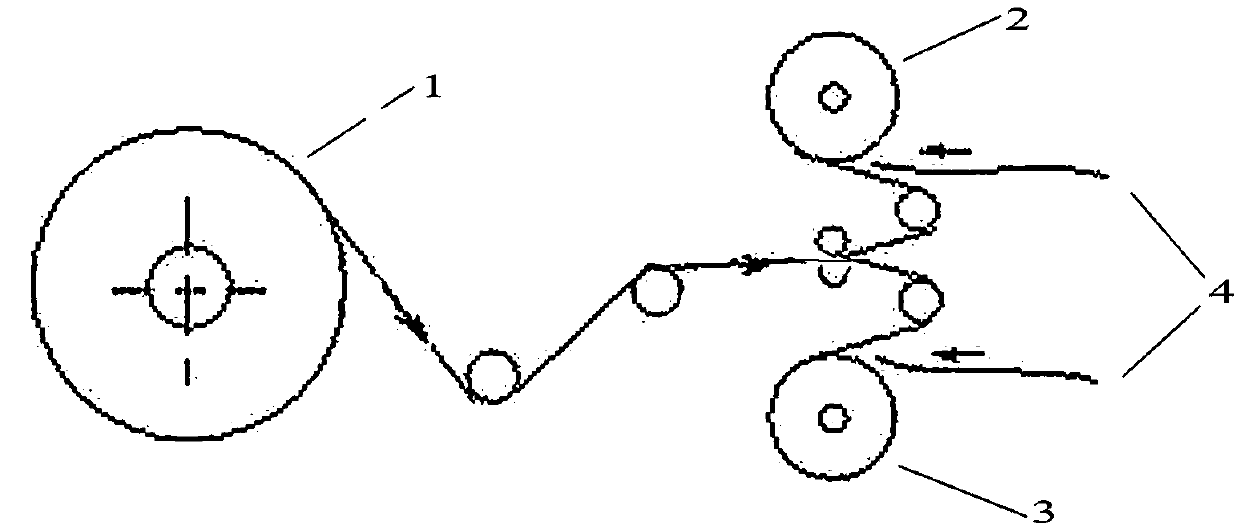

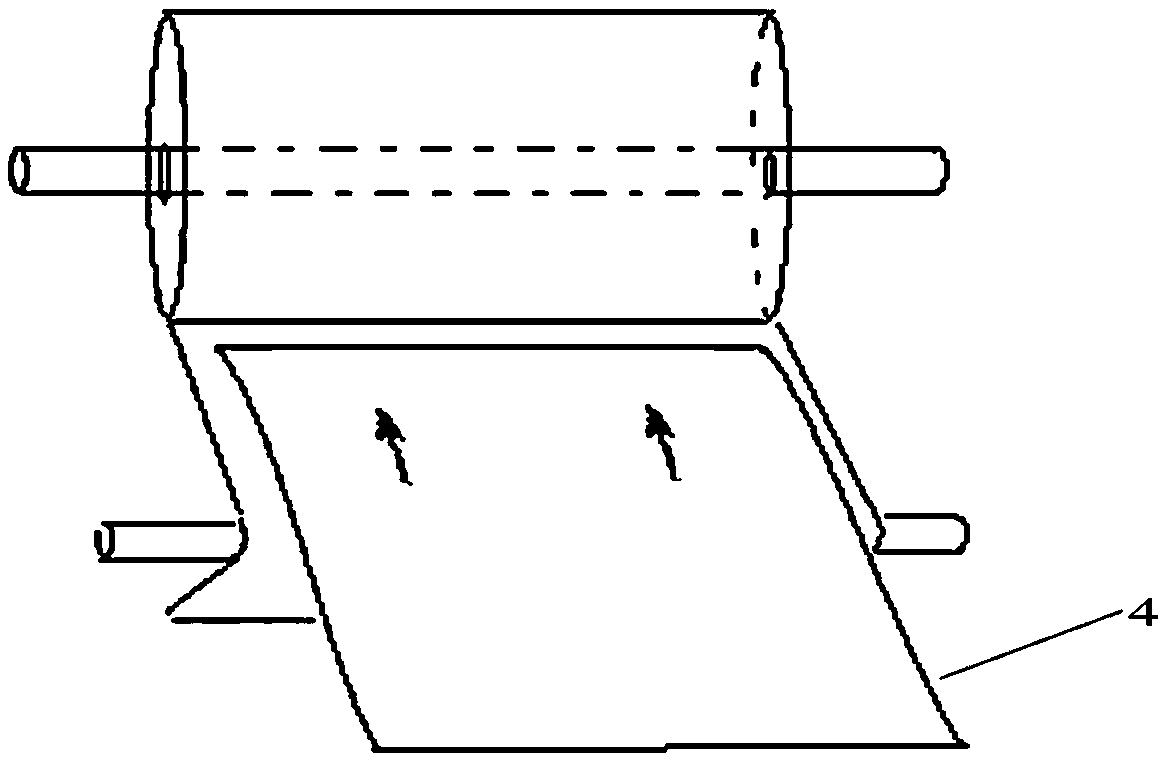

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030]

Embodiment 2

[0032]

Embodiment 3

[0034]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of non-ferrous metallurgical processing, and relates to a method for preventing aluminum foil from cracking after annealing, in particular to a method for preventing cracking after double-zero aluminum foil is annealed. The invention discloses a method for preventing scuffing after annealing of double-zero aluminum foil, which comprises the following steps: lining the refractory and heat-insulating material into the aluminum foil roll when the slitting and priming of the aluminum foil roll is completed and the slitting of the aluminum foil roll is about to end. The invention adopts the aluminum foil annealing prevention technology, which is simple and easy to implement and has excellent effect, and solves the problems of long annealing period, low annealing efficiency, large energy consumption and high production cost in the production implementation process of the original annealing process. With this method, the annealing cycle is shortened by 20% to 30% compared with the original method of slow heating and cooling in the furnace; the annealing cost is reduced by nearly 25%, and the reinvestment of the annealing furnace is reduced.

Description

technical field [0001] The invention belongs to the technical field of non-ferrous metallurgical processing, and relates to preventing aluminum foil from cracking after annealing, in particular to a method for preventing cracking after double-zero aluminum foil is annealed. Background technique [0002] Double-zero aluminum foil generally refers to aluminum foil with a thickness of less than 0.009mm. Because of its light-shielding, fresh-keeping, anti-corrosion and other properties, it is widely used as lining materials in cigarettes, food, medicine, electronics and other industries. It is used in conjunction with other packaging materials such as plastics, Substrates such as paper are laminated together to increase the strength of the packaging material. Aluminum foil is required to have good formability and bright and flat surface during use, and it is usually delivered in an annealed soft state. [0003] In the lamination process of aluminum foil and other packaging subs...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22F1/04

Inventor 刘文中

Owner JIANGSU DAYA ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com