A method and device for preparing a p-type doped amorphous silicon thin film

A technology of amorphous silicon thin film and preparation device, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, ion implantation and plating, etc., can solve the problem of low doping efficiency of P-type amorphous silicon thin film and low doping efficiency thin film defects And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

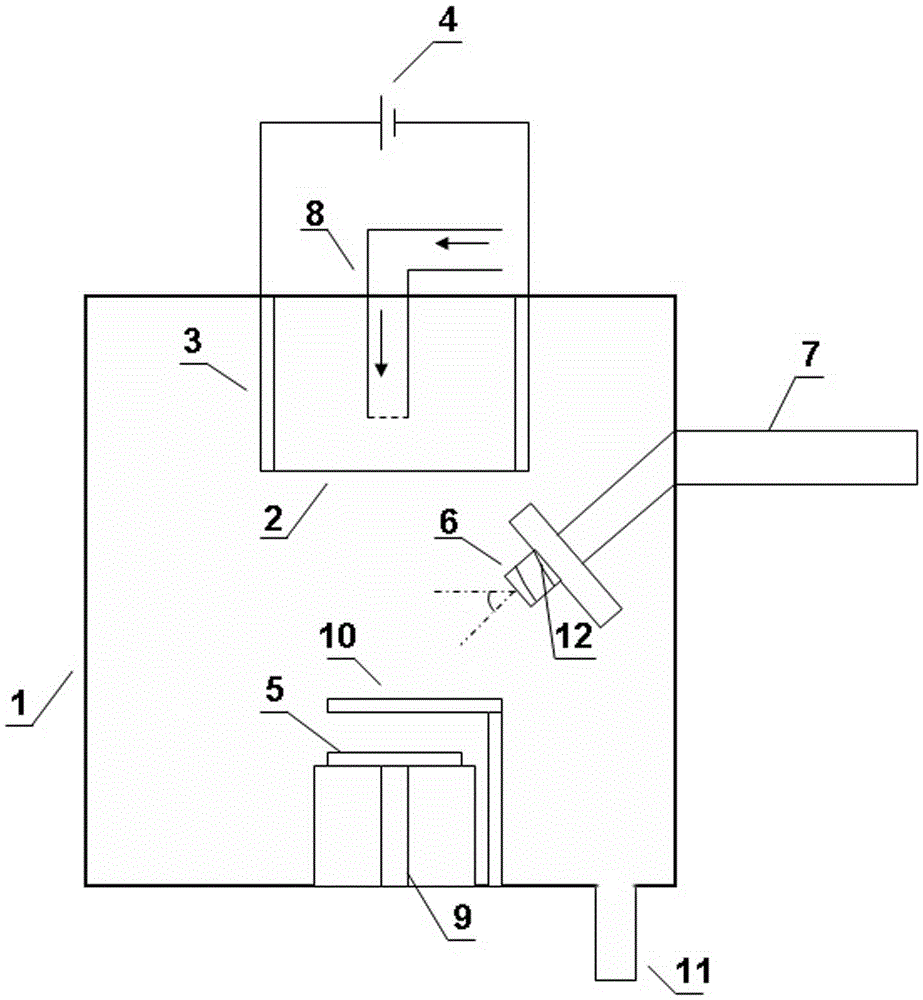

[0015] (1) adopt figure 1 In the shown device, the distance between the tantalum wire 2 and the substrate plate 5 is 10 cm, the angle between the surface normal of the ceramic crucible 6 and the plane of the substrate plate 5 is 80° C., and the aluminum source used in the thermal reaction evaporator 7 is 99.9999% aluminum purity;

[0016] (2) Put the AZO conductive glass on the substrate plate 5 in the vacuum chamber 1, and use the vacuum pump 11 to evacuate the vacuum chamber so that the vacuum degree of the vacuum chamber is 1×10 -4 Pa, and the temperature of the substrate plate 5 is controlled to be 200° C. by the substrate heater 9;

[0017] (3) Feed the mixed reaction gas hydrogen and silane into the vacuum chamber at the same time, the flow ratio of hydrogen and silane is 1:1, apply voltage to the tantalum wire 2 to heat, so that the temperature of the tantalum wire 2 reaches 1750°C, and the flow rate of the gas is controlled Make the pressure of the reaction gas in th...

Embodiment 2

[0022] (1) adopt figure 1 In the shown device, the distance between the tantalum wire 2 and the substrate plate 5 is 12 cm, the angle between the surface normal of the ceramic crucible 6 and the substrate plate plane is 75° C., and the purity of the aluminum source used in the thermal reaction evaporator 7 is 99.9999% Aluminum;

[0023] (2) Put the AZO conductive glass on the substrate plate 5 of the vacuum chamber 1, and use the vacuum pump 11 to evacuate the vacuum chamber so that the vacuum degree of the vacuum chamber is 1×10 -4 Pa, and the temperature of the substrate plate 5 is controlled to be 200° C. by the substrate heater 9;

[0024] (3) Feed the mixed reaction gas hydrogen and silane into the vacuum chamber at the same time, the flow ratio of hydrogen and silane is 1.2:1, apply voltage to the tantalum wire 2 to heat, so that the temperature of the tantalum wire 2 reaches 1700 ° C, through the flow control of the gas Make the pressure of the reaction gas in the vac...

Embodiment 3

[0029] (1) adopt figure 1 In the shown device, the distance between the tantalum wire 2 and the substrate plate 5 is 15 cm, the angle between the surface normal of the ceramic crucible 6 and the substrate plate plane is 85° C., and the purity of the aluminum source used in the thermal reaction evaporator 7 is 99.9999% Aluminum;

[0030] (2) Put the AZO conductive glass on the substrate plate 5 in the vacuum chamber 1, and use the vacuum pump 11 to evacuate the vacuum chamber so that the vacuum degree of the vacuum chamber is 1×10 -4 Pa, and the temperature of the substrate plate 5 is controlled to be 200° C. by the substrate heater 9;

[0031] (3) Feed the mixed reaction gas hydrogen and silane into the vacuum chamber at the same time, the flow ratio of hydrogen and silane is 1.5:1, apply voltage to the tantalum wire 2 to heat, so that the temperature of the tantalum wire 2 reaches 1750°C, and the flow rate of the gas is controlled Make the pressure of the reaction gas in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com