Prefabricated non-cushion permeable ecological grass-planting lawn and its mold and construction method

An ecological and ecological technology, applied in the field of prefabricated non-cushion permeable ecological grass lawn, can solve the problems of increased maintenance cost, difficulty in forming a whole, waste of water resources, etc., to achieve long-term growth, humanized design, and improved vitality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

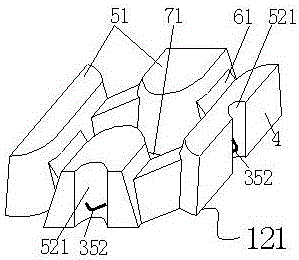

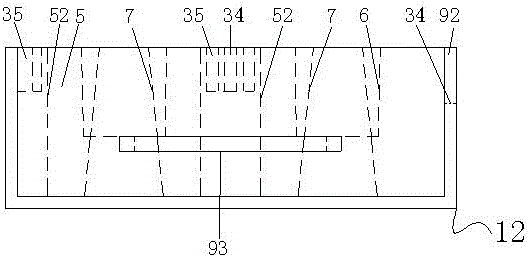

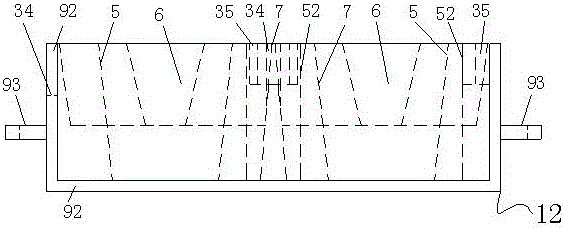

[0059] Such as Figure 16 As shown in the combined construction effect diagram of the prefabricated ecological floor of the present invention, the ecological floor of the present invention includes a strip tread body 51 , connecting beams 61 , planting pits 71 , and edge beams 9 .

[0060] The strip-shaped stepping body 51 is an enlarged foot shape from top to bottom, such as Figure 4 As shown, the two ends of the bar-shaped stepping body 51 are arc-shaped. The connecting beam 61 is enlarged from top to bottom, such as image 3 As shown, the height of the connecting beam 61 is lower than that of the strip-shaped stepping body 51 . The connecting beam 61 and the strip-shaped stepping body 51 form a planting pit 71 . The horizontal section of the planting pit 71 is gradually reduced from top to bottom.

[0061] There are side beams 9 around the outermost sides of the ecological floor of the present invention. The height of the side beam 9 is the same as that of the strip-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com