Inflatable filling house and construction method thereof

A construction method and house technology, applied in special structures, building components, etc., can solve the problems of too light weight, poor heat insulation effect, unsafe, etc., and achieve short installation time, high stability and safety, and less labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

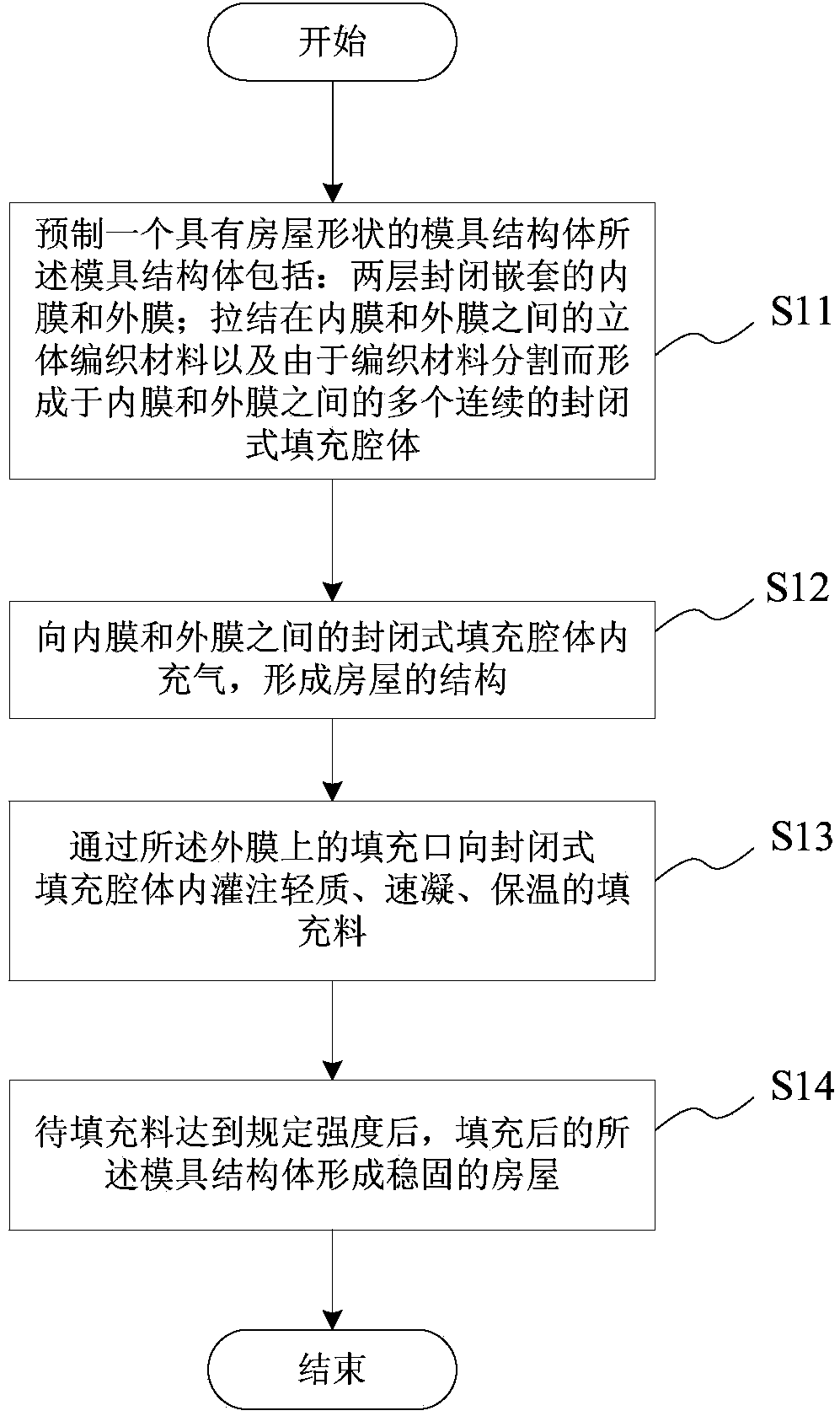

[0053] like figure 1 As shown, the present embodiment provides a construction method of an inflatable filled house, figure 1 Shown as a flow chart of the construction method of the inflatable filled house of the present invention, as figure 1 As shown, the construction method includes the following steps:

[0054] Step S11, prefabricating a mold structure in the shape of a house.

[0055] Step S12, inflate air into the closed filling cavity between the inner membrane and the outer membrane, and the inflated mold structure forms the structure of the house.

[0056] Step S13, filling the closed filling cavity with lightweight, quick-setting and heat-retaining filling material through the filling port on the outer membrane;

[0057] Step S14, after the filling material reaches the specified strength, the filled mold structure forms a stable house.

[0058] The specific steps of the construction method are described in detail below.

[0059] Step S11, prefabricating a mold st...

Embodiment 2

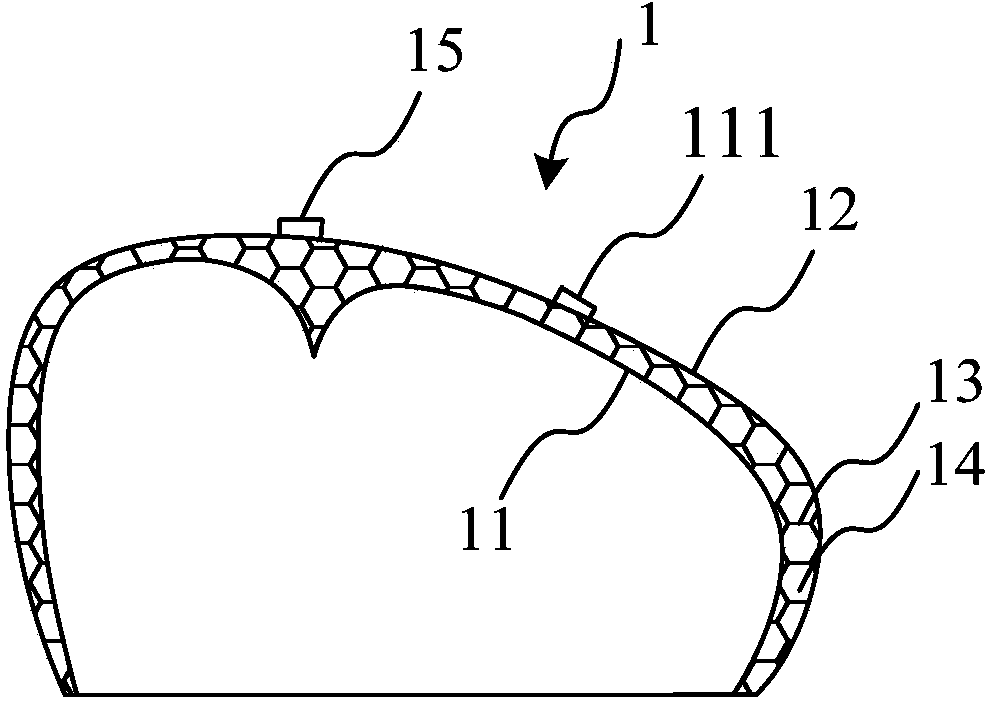

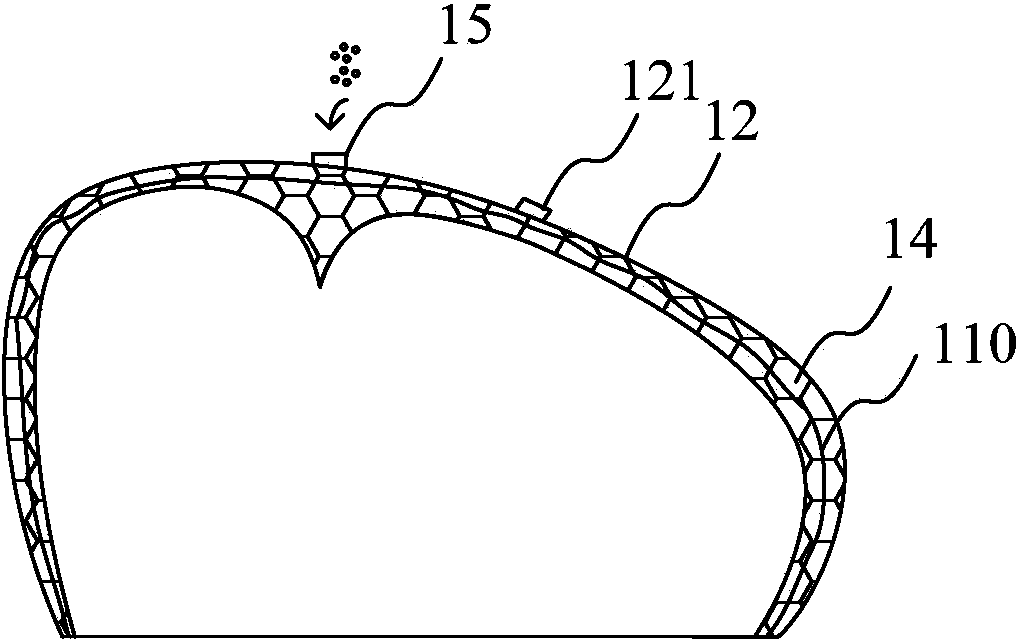

[0092] This embodiment provides an inflatable filled house 1 constructed according to the method of Embodiment 1, such as Figure 2 to Figure 5 As shown, the inflatable filled house 1 includes a mold structure with a house shape, two layers of closed and nested inner membrane 11 and outer membrane 12; a three-dimensional braided material 13 between the inner membrane 11 and the outer membrane 12 and Due to the division of the braided material 13, a plurality of continuous closed filling cavities 14 are formed between the inner membrane 11 and the outer membrane 12; The filling port 15 of the solid and firm filling material 18 and the outer film inflation port 121 for inflating the closed filling cavity 14; each closed filling cavity 14 corresponds to a filling port 15 and an outer film inflation port Mouth 121. The space formed below the inner membrane 11 is the interior space of the house, and this interior space should have a height and width suitable for people to live and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com