Hole Reaming Method for Coal Seam Passage

A channel and coal seam technology, applied in the field of hole reaming of coal seam channels, can solve the problems of slow pore size, uneven pore size, and slow coal seam burning speed of gasification channels, so as to achieve smooth combustion expansion, avoid uneven pore size, The effect of uniform temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

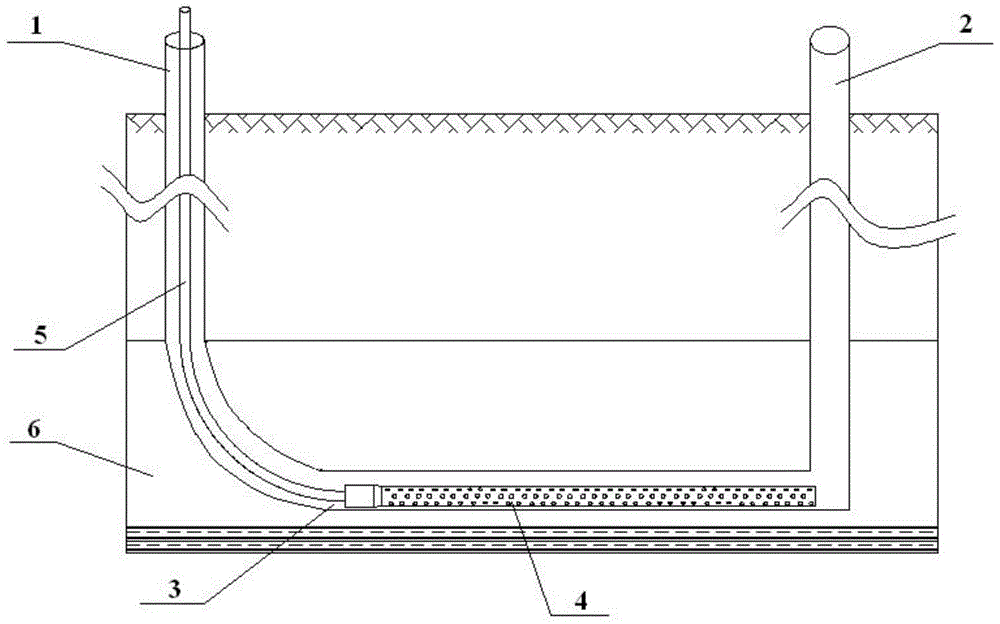

[0028] refer to figure 1 , the vertical first channel 1 and the second channel 2 and the coal seam channel 3 connecting the first channel 1 and the second channel 2 are established from the ground to the coal seam 6 . Then perform the following steps: a. laying high-energy inflammables in the coal seam channel 3; b. injecting a combustion-supporting agent into the coal seam channel 3, and igniting the high-energy inflammables; c. continuously injecting the combustion-supporting agent. Among them, the coal seam channel 3 is a channel located in the coal seam 6. In an actual UCG, the coal seam channel 3 may include a channel section located in the coal seam 6 on the intake channel, a channel section located in the coal seam 6 on the gas outlet channel, Gasification channels and channels for other purposes. Among them, preferably, the hole expanding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com