Eccentrically oscillating reduction gear, and method for manufacturing eccentric body shaft

A technology of eccentric swing and manufacturing method, applied in the direction of eccentric shaft, manufacturing tool, furnace type, etc., to achieve the effect of improving qualitative characteristics, prolonging life and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] [Concrete Problems of the Invention and Their Solution Principles]

[0031] The present invention is based on the knowledge of elucidating the mechanism of deterioration (damage or wear) of the eccentric body shaft, which has not been fully verified in the past. The specific problem to be focused on is not known in itself, so before proceeding to the description of the embodiment, first, the specific problem to be focused on in the present invention and the principle of its solution will be described in detail.

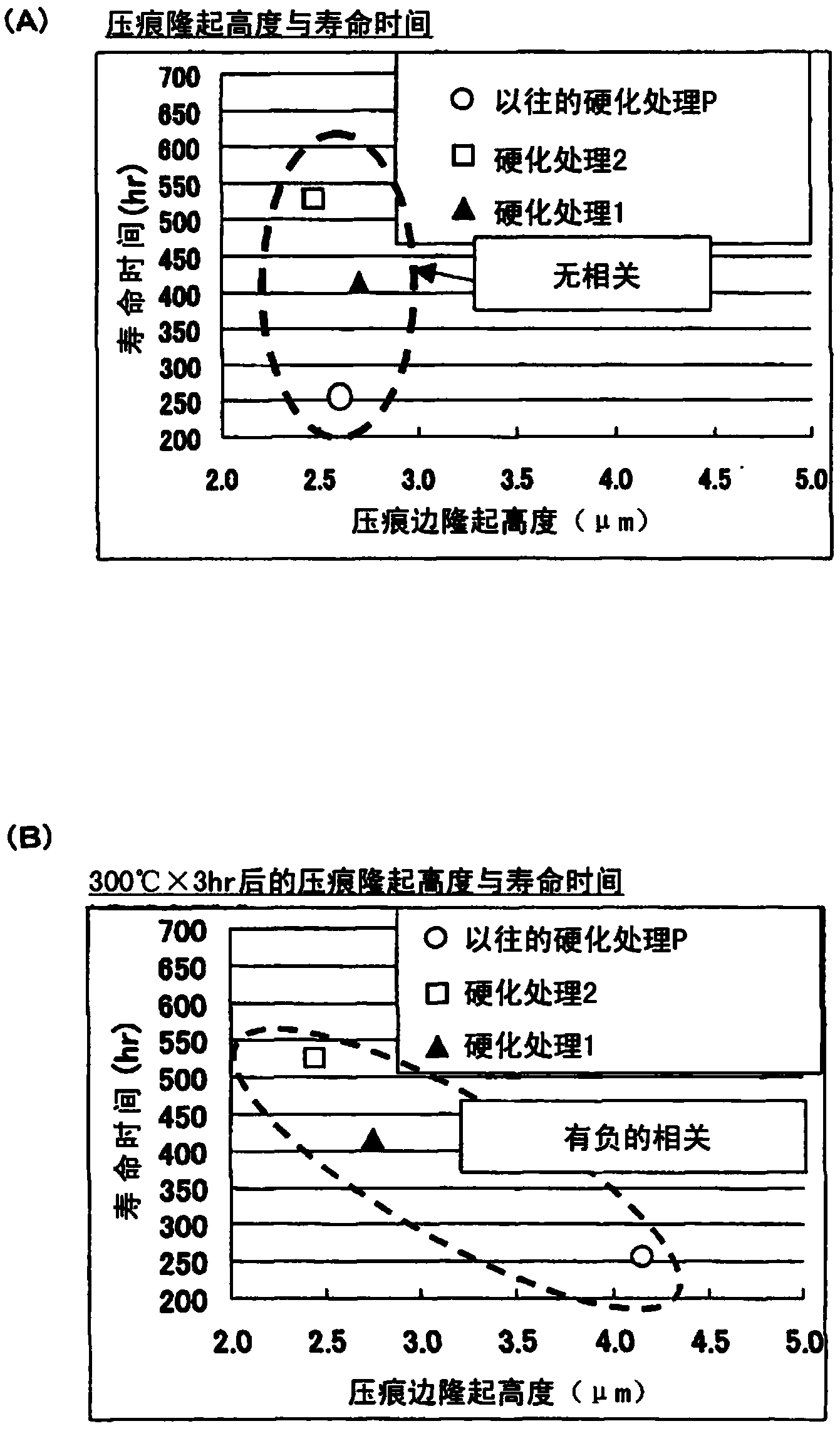

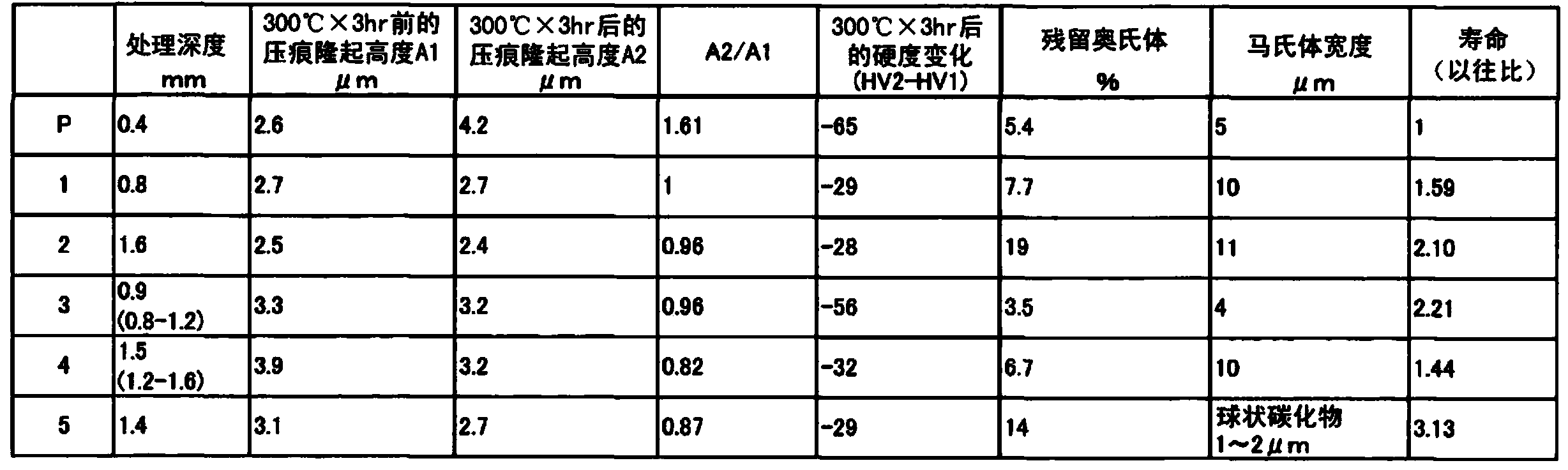

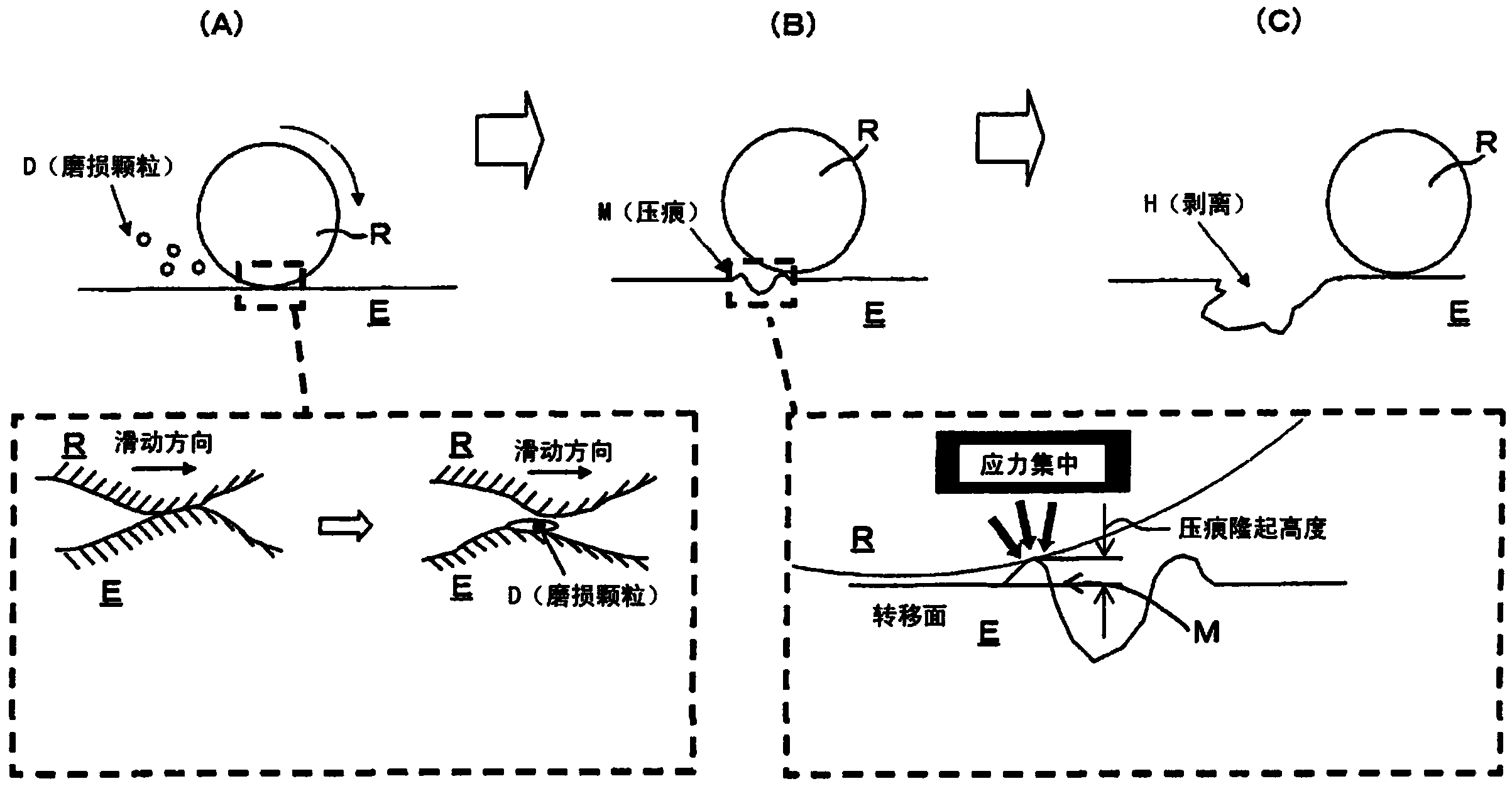

[0032] The inventors presumed the following mechanism as one of the mechanisms (causes) of the deterioration of the eccentric body shaft: image 3 As shown, when foreign matter such as gear wear particles D is mixed between the eccentric body E of the eccentric body shaft and the eccentric body bearing (the rolling element) R, a small indentation M occurs on the surface of the eccentric body E ( figure 1 A→B), the stress is concentrated on the edge of the ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com