High-inclination small-flange conical roller bearing

A tapered roller bearing, a technology of large inclination, applied in the field of bearings, can solve the problems of large differences in the force decomposition of the rib, the shape of the oil groove is not standardized, and a large impact force is generated, so as to reduce the acting force and avoid the rib. The effect of shattering and increasing the inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

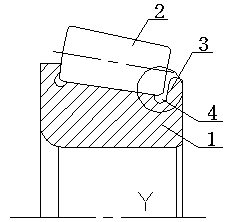

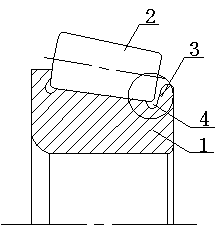

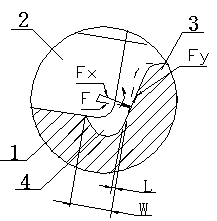

[0013] The tapered roller bearing with large slope and small ribs disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] The tapered roller bearing with large slope and small rib in the present invention has the structure as follows: figure 2 As shown, it includes bearing inner ring 1, rolling element 2 and small rib 3, wherein the end of bearing inner ring 1 extends outward to form small rib 3, and the root of small rib 3 and the outer surface of bearing inner ring 1 are formed The oil groove 4, the rolling body 2 is arranged on the outer surface of the bearing inner ring 1, and the end of the rolling body 2 is just above the oil groove 4 and does not contact the inner surface of the small rib; the present invention increases the size of the small rib The inclination of the inner surface of the edge, there is an acute angle between the end surface of the rolling element and the inner surface of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap