Single-water-path ceramic valve element structure

A ceramic spool and single waterway technology, which is applied in sliding valves, valve devices, engine components, etc., can solve the problems of human body injury, spool easy to leak, and poor water safety of the spool, so as to reduce the force strength requirements, The effect of improving water safety and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

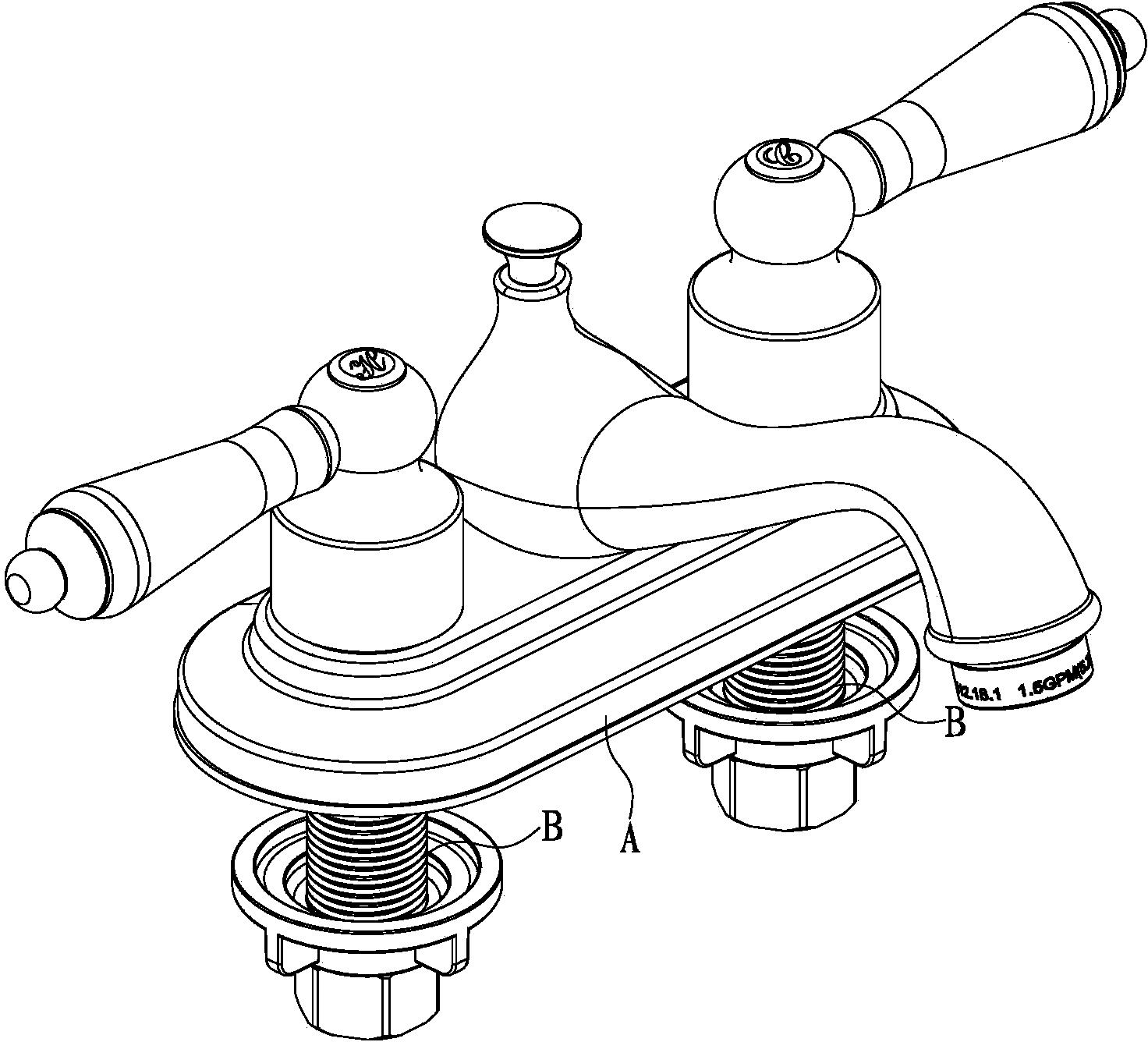

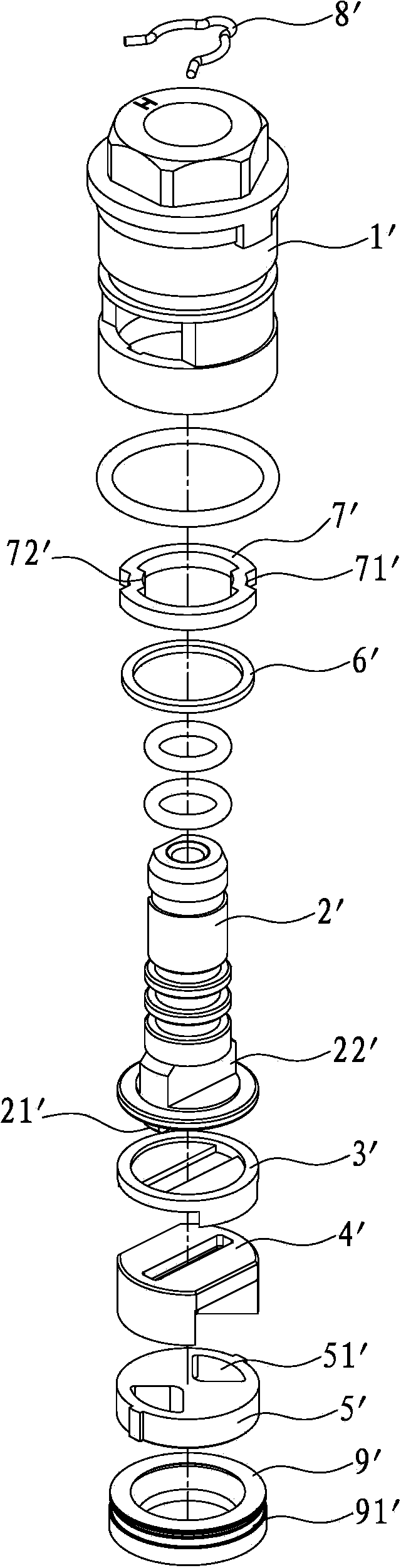

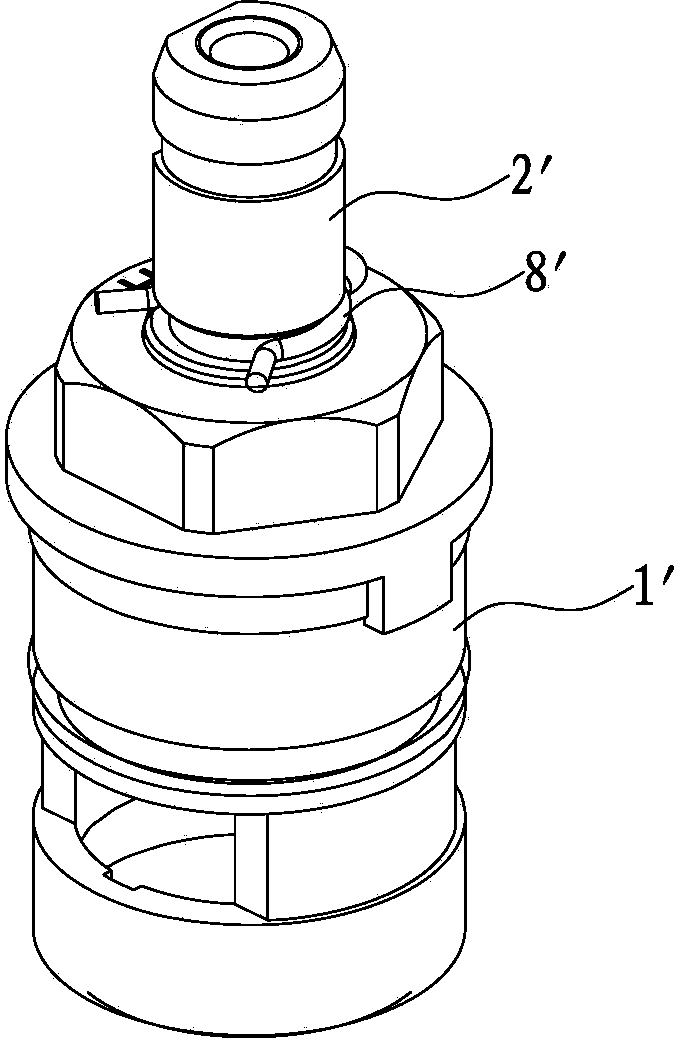

[0038] like Figure 7 to Figure 13 and cooperate figure 1 As shown, the present invention discloses a single-water channel ceramic valve core structure, which is respectively assembled in the cold and hot water inlet pipes B of the faucet A; it includes a valve housing 1, a valve stem 2, a base 3, a The upper ceramic sheet 4, the lower ceramic sheet 5 and the sealing ring 6; an arc-shaped groove 11 is formed on the side wall of the upper part of the valve housing 1, and a water outlet 12 is formed on the lower side wall; the base 3 is an upper chamber 31 with no communication The cylinder sleeve of the lower chamber 32 has a matching hole 33 corresponding to the arc groove 11 of the valve casing 1 on its upper part; and a horizontal assembly hole 21 is provided on the lower part of the valve stem 2, and the base 3 is sealed and assembled on the valve body from bottom to top. In the casing 1, the valve stem 2 passes through the valve casing 1 from top to bottom and is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com