Top entry low temperature ball valve

A low-temperature, ball valve technology, used in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as potential safety hazards, reduced reliability of valve seat and valve disc sealing, etc., to ensure sealing performance and improve use. Long life, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

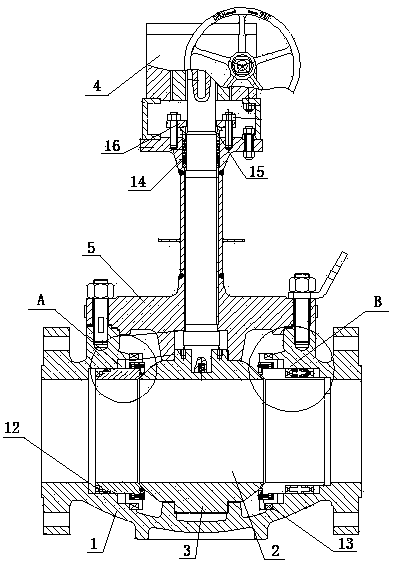

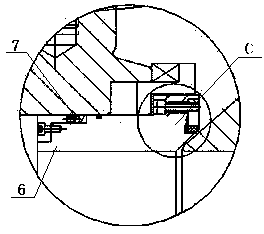

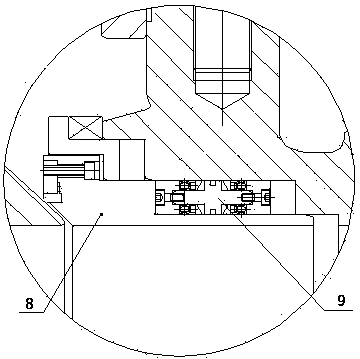

[0019] Such as figure 1 — Figure 5 As shown, the top-entry low-temperature ball valve includes a valve body 1, a ball 2, a valve stem 3 and an actuator 4. The valve body 1 has an inlet and an outlet. In the cavity of the valve body 1, the upper part of the valve body 1 is fixedly connected with a valve cover 5 by bolts, one end of the valve stem 3 is connected with the ball 2, and the other end of the valve stem 3 is connected with the actuator 4, and the valve stem 3 is connected with the actuator 4. The actuator 4 drives the ball 2 to rotate through the valve stem 3 to realize the switch of the ball valve. An inlet valve seat 6 is provided between the inlet of the valve body 1 and the ball 2, and a single lip seal is arranged on the left side of the inlet valve seat 6. Ring 7, an outlet valve seat 8 is provided between the outlet of the valve body 1 and the ball 2, and a double-lip sealing ring 9 is provided on the right side of the outlet valve seat 8.

[0020] A valve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com