Electric blasting valve

A valve and electric explosion technology, which is applied in the field of oil circuit and gas circuit, can solve problems such as inability to work stably, achieve high reliability, and increase the diameter of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

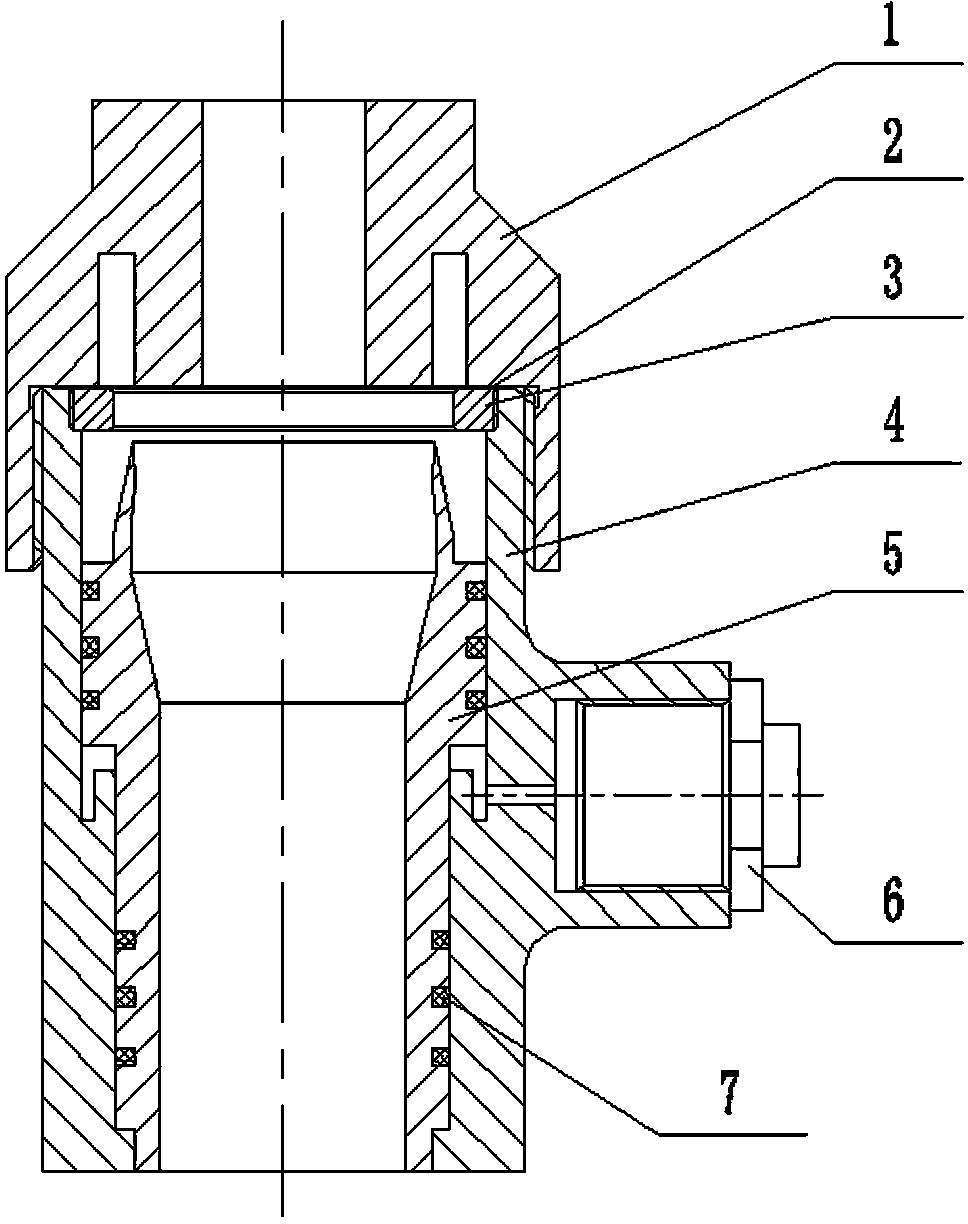

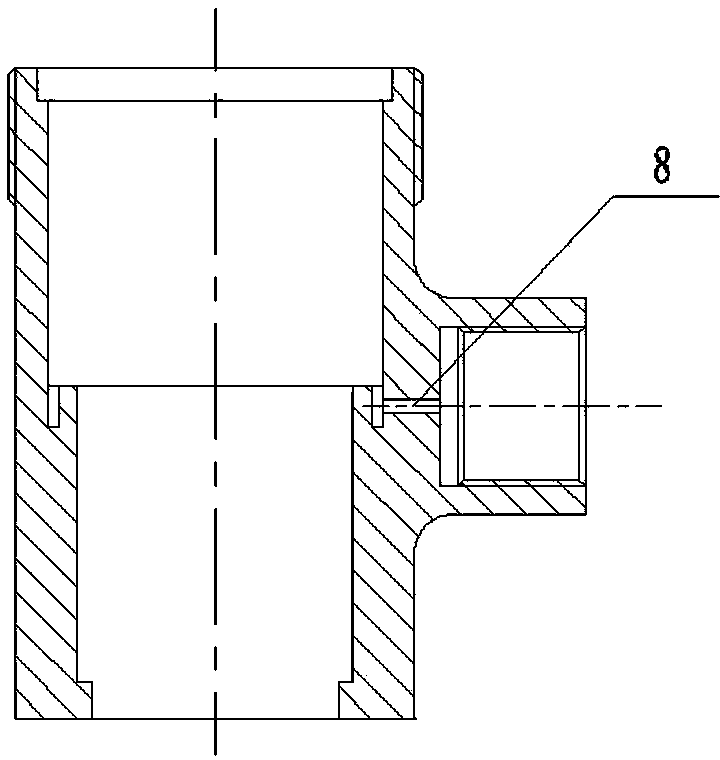

[0024] After cutting the diaphragm with a cutter, the design idea of forming a passage inside the cutter, but directly changing the start-up electric explosion valve in the prior art into a large-diameter structure, there is an instantaneous high pressure when the gas and liquid circuits are connected, and the cutting Knife bounces back, blocks again the defect of gas, liquid path, and valve volume increases obviously simultaneously, and negative mass is bigger, and this is the technical problem that must be solved in the design of the present invention. The invention adopts the structural design of the passage formed inside the cutter, and the pressure leaks from the inside of the cutter after starting, which will not cause the rebound of the cutter, and at the same time, the product has a small volume under the requirement of a large diameter.

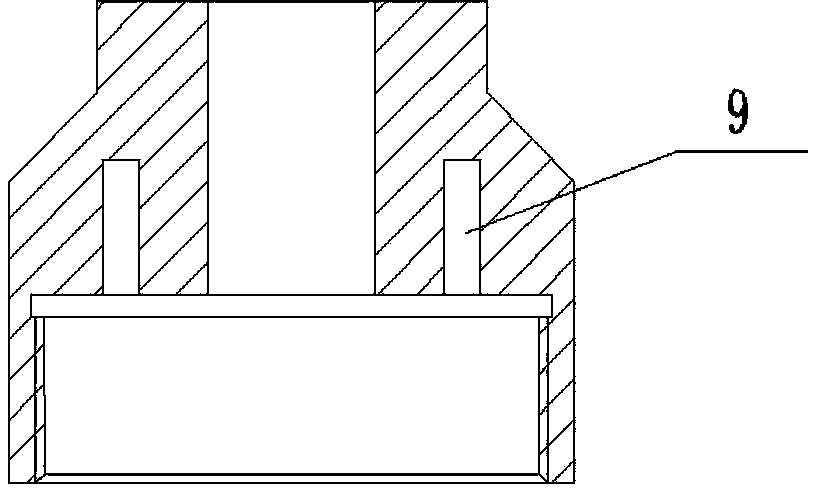

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com