Leakage detection device of base surface of fuel oil common-rail control valve body

A leak detection device and a technology for controlling valve bodies, which are applied in the direction of measuring the acceleration and deceleration rates of fluids and using liquid/vacuum degree for liquid tightness measurement, etc. Blocking, leakage and other problems, to achieve the effects of good environmental protection, reduced leakage detection costs, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

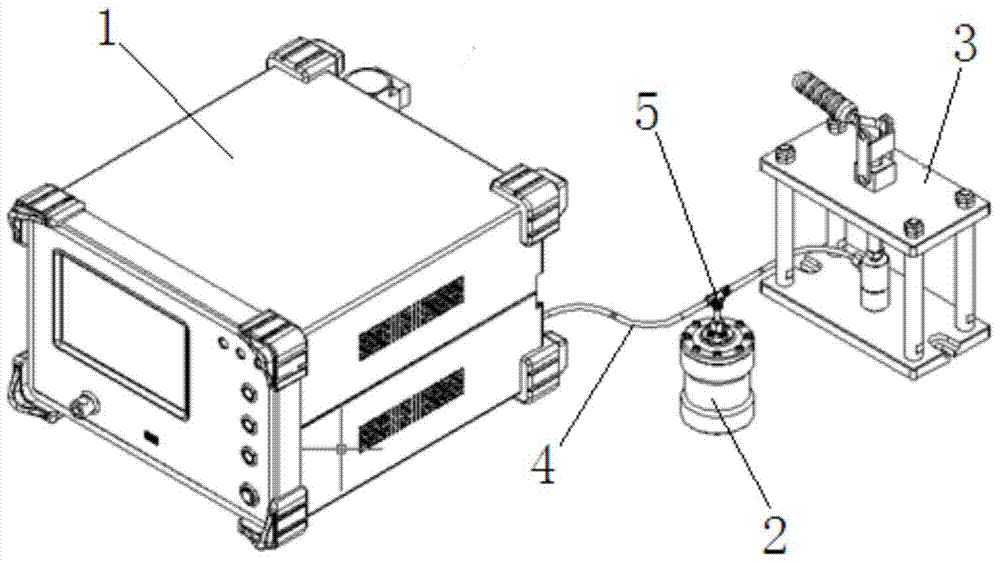

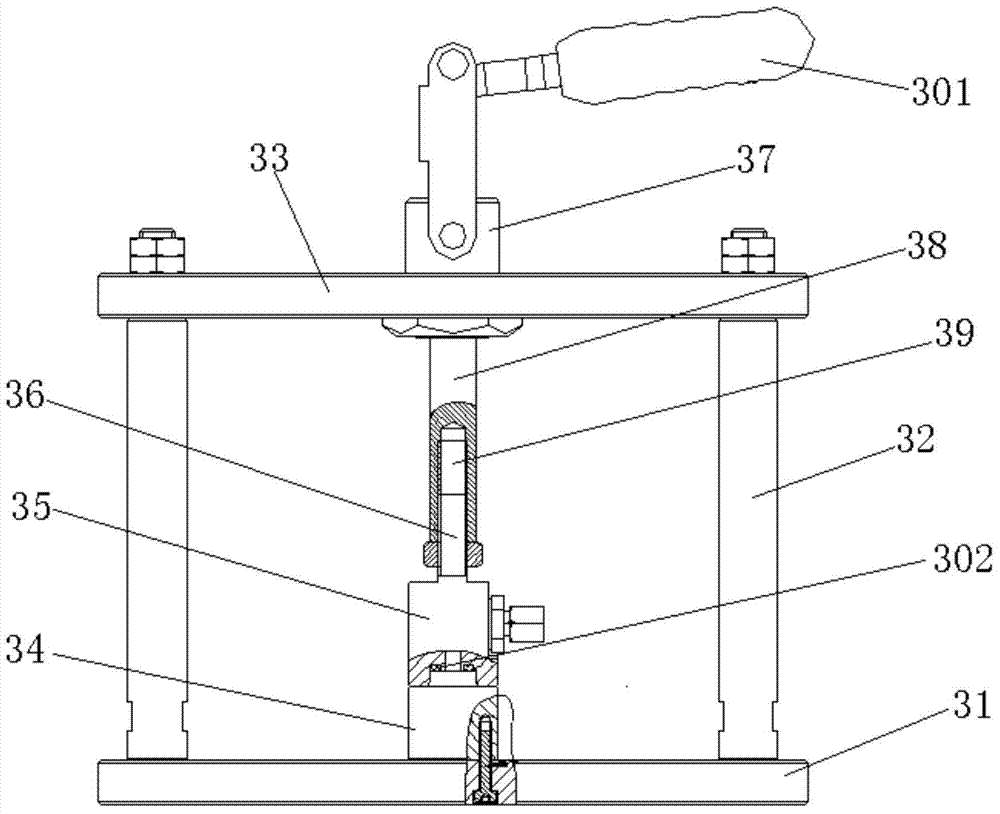

[0012] Such as figure 1 , figure 2 shown. A leak detection device for a seat surface of a fuel common rail control valve body, comprising a differential pressure airtight leak detector 1, a volume expansion device 2, and a plugging and positioning device 3. The plugging and positioning device 3 includes a bottom plate 31 with four corners on the bottom plate 31 Positions are vertically connected with guide rods 32 respectively, the tops of the guide rods 32 jointly support an upper plate 33, the center of the bottom plate 31 top is provided with a support block 34, the top of the support block 34 is placed with a briquetting block 35, and the bottom of the briquetting block 35 faces the briquetting block 35. There is a groove in the middle, the top of the pressure block 35 is vertically connected with a guide column 36, the center of the top of the upper plate 33 is provided with a slide seat 37, and a press seat 38 is vertically slid in the slide seat 37, and the bottom end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com