Sealing performance detection device for potato food production

A sealing detection and food technology, which is applied in the field of sealing detection devices for potato food production, can solve the problems of inconvenient use, low accuracy, and inconvenience of distinguishing packaging bags, etc., to reduce workload, facilitate operation, and ensure normal operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

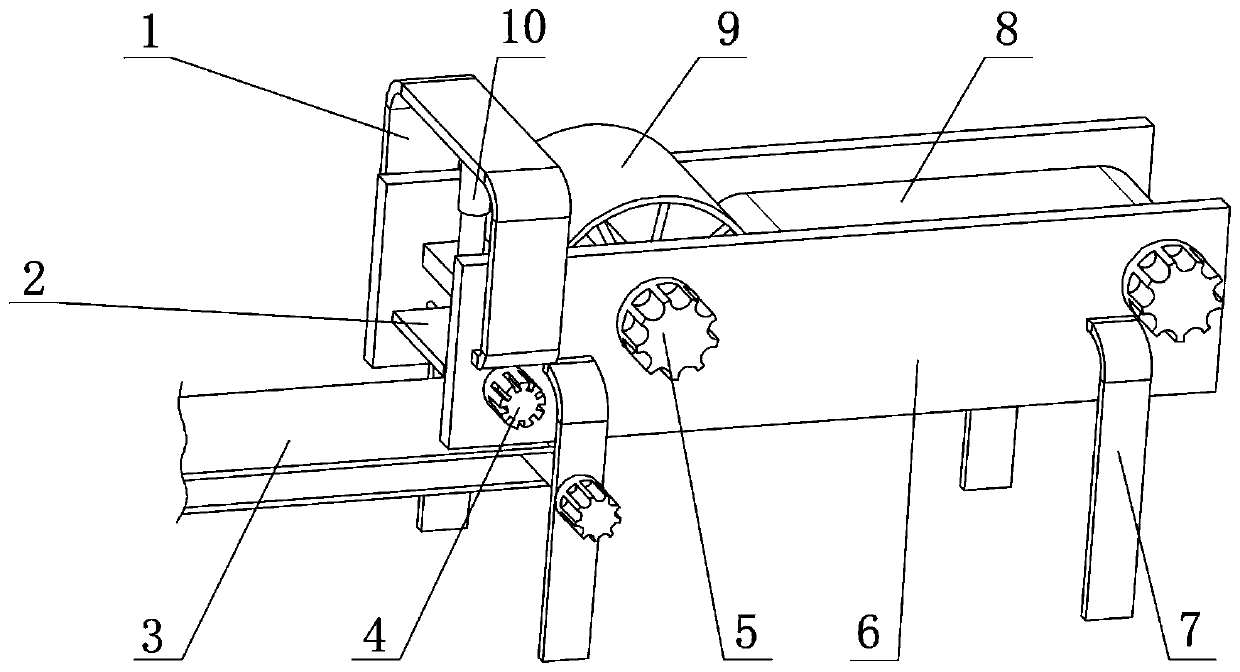

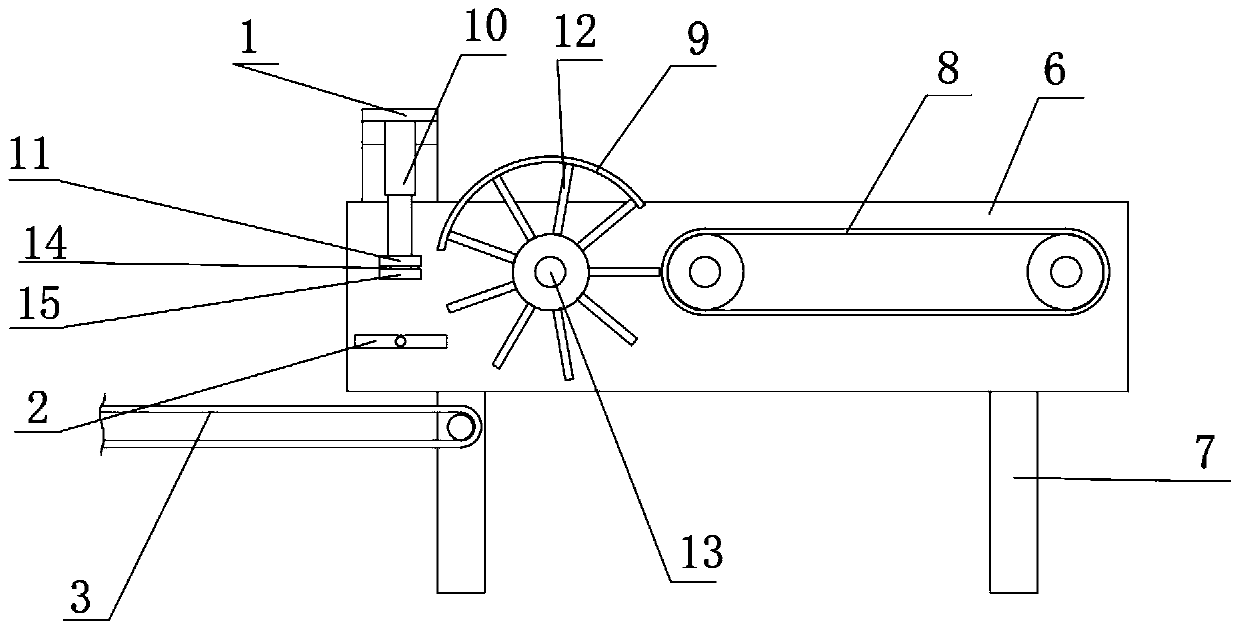

[0024] refer to Figure 1-2 , a leak detection device for potato food production, comprising two mounting plates 6, the outer wall of one end of the two mounting plates 6 away from each other is installed with the same first connecting frame 1, and the outer wall of the bottom of the first connecting frame 1 is mounted with The electric telescopic rod 10 is equipped with a fixed plate 11 on the outer wall of the bottom of the electric telescopic rod 10, and two pressure sensors 14 are installed on the outer wall of the bottom of the fixed plate 11, and the same pressure plate 15 is installed on the outer wall of the bottom of the two pressure sensors 14, and two mounting plates 6 The same first electric conveyor belt 8 is installed on one side of the outer wall at the opposite end, and a controller and an alarm are installed on the outer wall at the bottom of one of the mounting plates 6 .

[0025] In the present invention, the opposite side of the outer wall at one end of the...

Embodiment 2

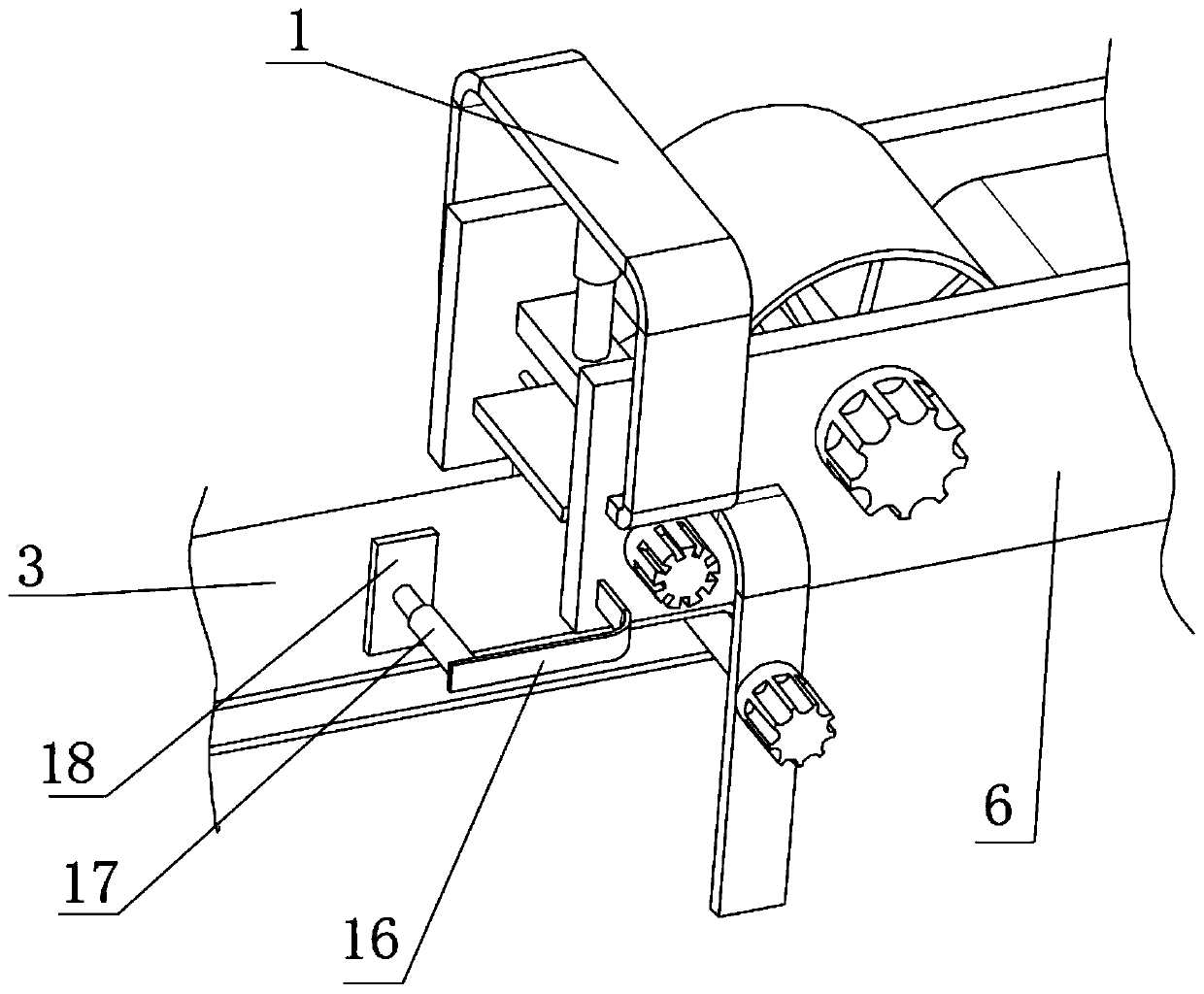

[0028] refer to Figure 1-3 , a leak detection device for potato food production, also includes a second connecting frame 16 installed at the bottom of the outer wall at one end of the mounting plate 6, and an electric push rod 17 is installed on the outer wall at one end of the second connecting frame 16, and the electric push rod 17 one end outer wall is equipped with push plate 18.

[0029] Working principle: Compared with embodiment 1, when the pressure sensor 14 detects that the pressure changes, the controller controls the electric push rod 17 to start, and the unqualified packaging bags are pushed out from the second electric conveyor belt 3 without working Personnel guarding reduces the workload of the staff.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com