Pressurization visual combustion test device of combustor of gas turbine

A technology of gas turbine and combustion test, applied in the direction of measuring device, engine test, machine/structural component test, etc., to achieve the effect of cheap material, good perspective and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

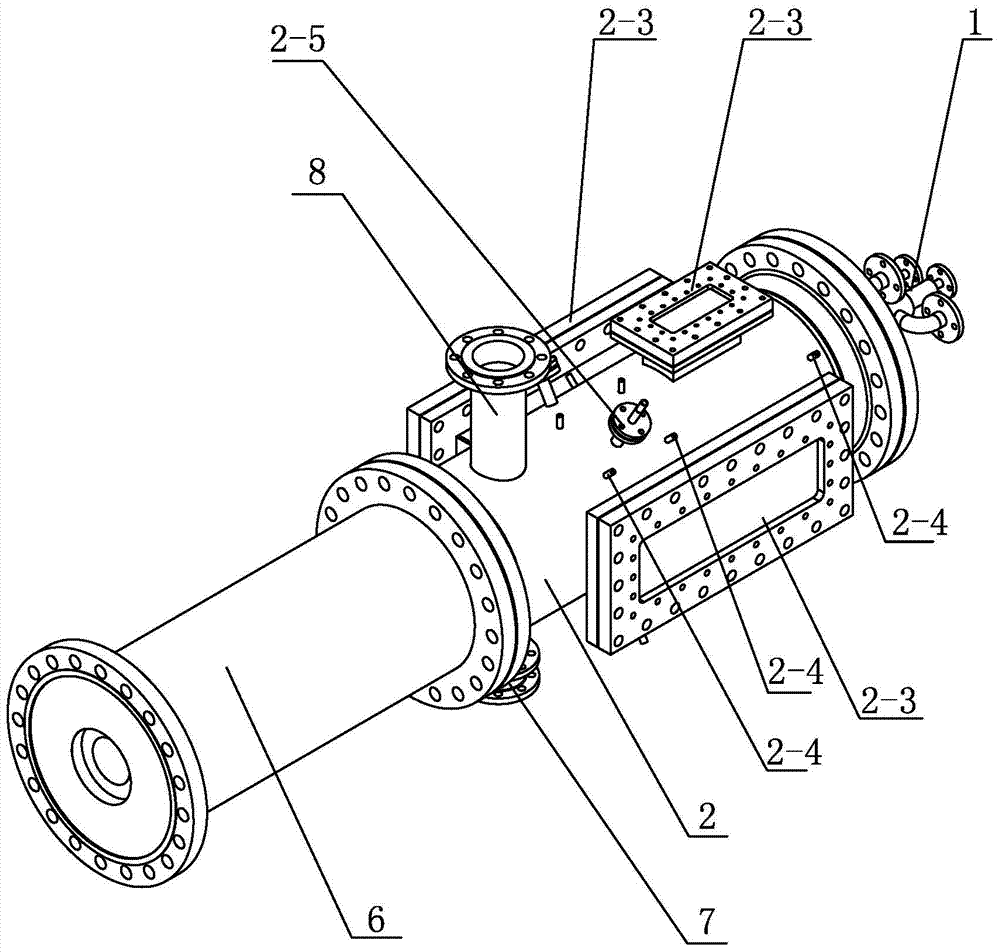

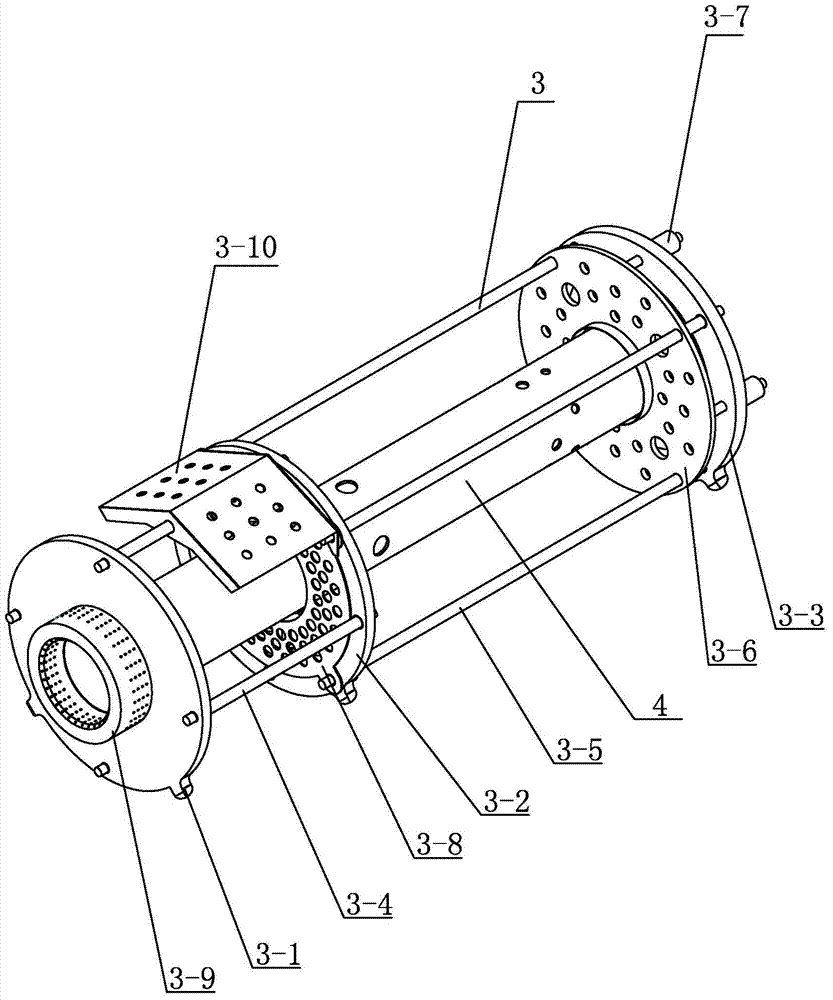

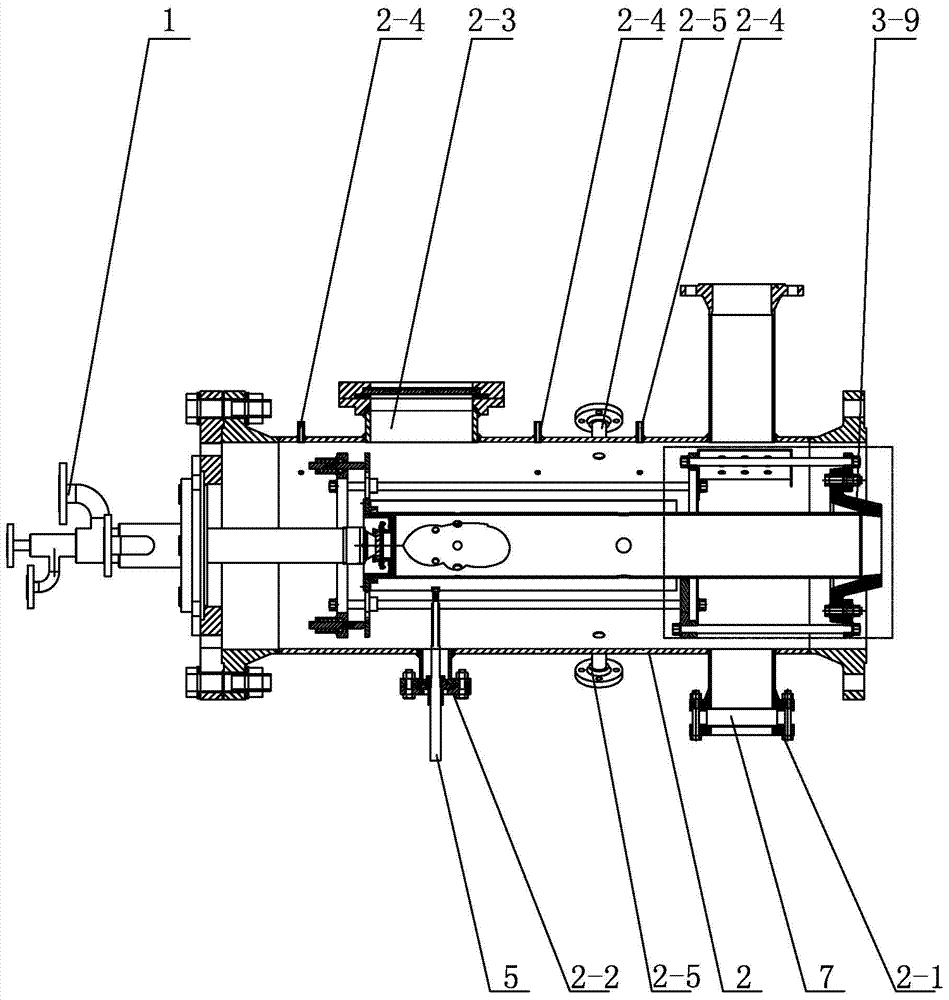

[0007] Specific implementation mode one: combine figure 1 , figure 2 with image 3 To illustrate this embodiment, the gas turbine combustor pressurized visual combustion test device described in this embodiment includes a single nozzle installation flange cover 1, a pressure-bearing casing 2, an elastic bracket assembly 3, a quartz glass flame tube 4, and a telescopic igniter 5. The high temperature measurement section 6 and the explosion-proof mechanism 7, the pressure casing 2 is set horizontally, the single nozzle installation flange cover 1 is installed on the end face of one end of the pressure casing 2, the pressure casing 2 is connected with the high temperature measurement section 6, The explosion-proof mechanism 7 is installed on the explosion-proof clamping flange 2-1 on the lower surface of the pressure-bearing casing 2, the elastic bracket assembly 3 is inserted in the pressure-bearing casing 2, and the glass flame tube 4 is adapted to be inserted into the elasti...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 with image 3 Describe this embodiment, the gas turbine combustor pressurized visual combustion test device described in this embodiment is respectively provided with a viewing window 2-3 on the upper surface and two sides of the pressure casing 2, and the upper surface of the pressure casing 2 is Three rows of temperature and pressure measuring points 2-4 are arranged at equal intervals on the upper surface, and two secondary diluent interface flanges 2-5 are respectively arranged on the upper surface and the lower surface of the pressure-bearing casing 2.

[0010] In this embodiment, after the compressed air enters from the inlet flange on the pressure-bearing casing 2, the air state parameters at the inlet of the tester are measured through the temperature and pressure measuring points 2-4, and then the four secondary diluent interface flanges 2-5 are downstream The compressed air is mixed with the secondary dil...

specific Embodiment approach 3

[0012] Specific Embodiment 3: This embodiment is described in conjunction with 1. Each viewing window 2-3 of the gas turbine combustor pressurized visual combustion test device in this embodiment is a viewing window 2-3 made of synthetic adaptive glass.

[0013] The technical effect of this embodiment is: so set, the peep window 2-3 can not only pass through the far ultraviolet spectrum, but also can pass through the visible light and near-infrared spectrum, can work at a temperature above 950°C for a long time, and realize it at a temperature above 1200°C Working at the maximum cycle, the three peep windows 2-3 are used in conjunction with each other, so that the combustion flame in the quartz glass flame tube 4 can be observed by the experimenter with the naked eye, and can cooperate with the combustion optical measurement system to measure the flame in the quartz glass flame tube 4 form and structure. Other components and connections are the same as those in the second embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com