trickle dispenser

A dispenser and trickle technology, applied in the field of trickle dispensers, can solve the problems of incomplete dispensing of drops, atomization of fluid products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

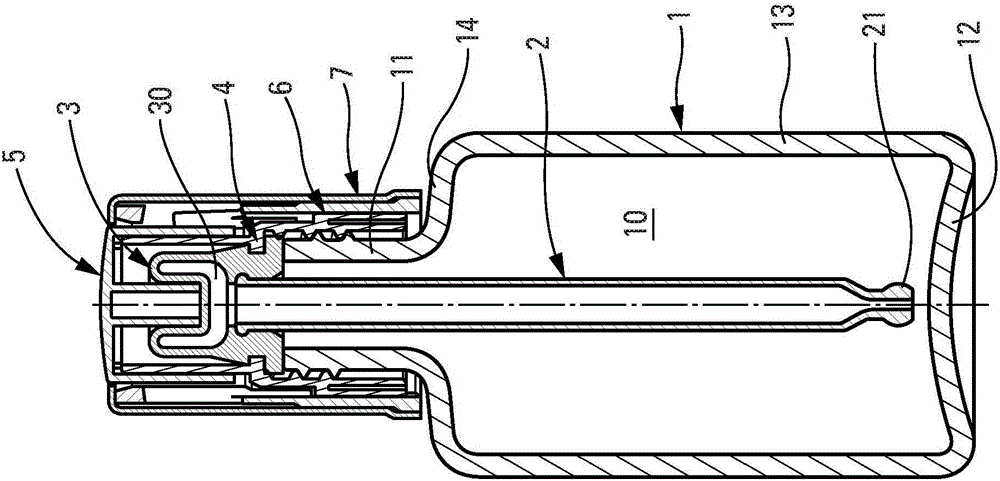

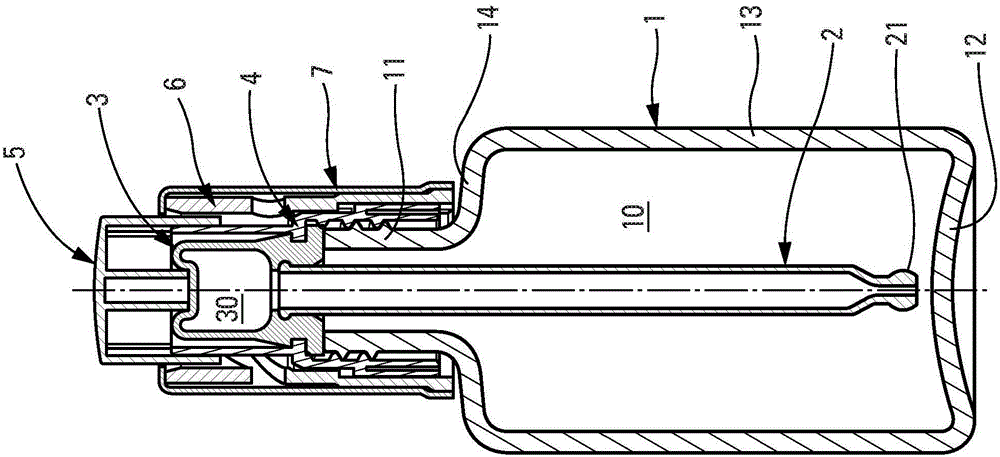

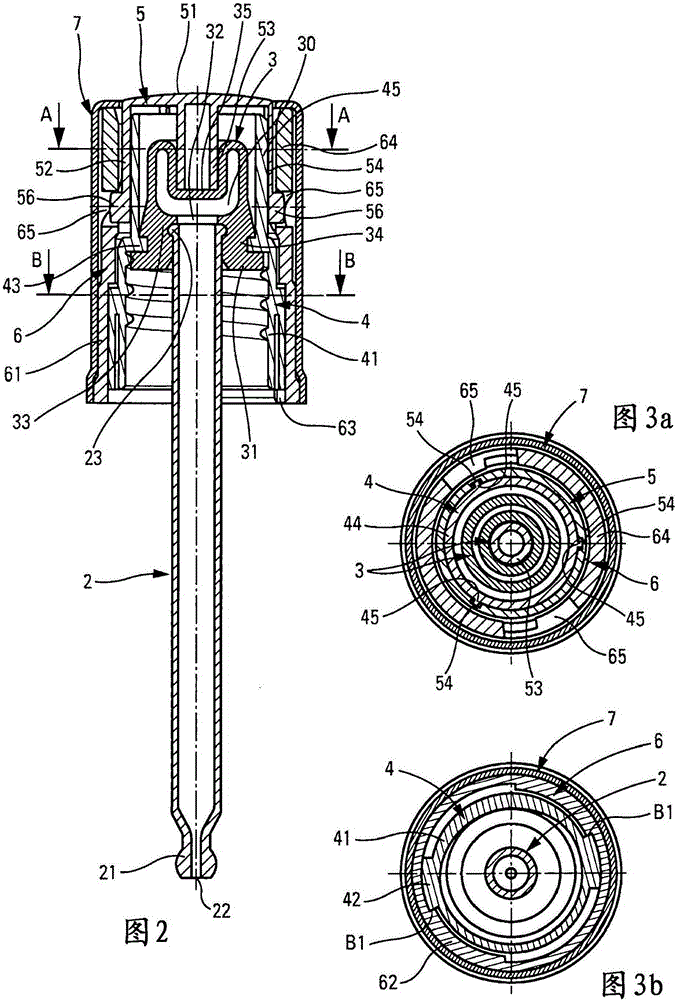

[0024] First refer to Figure 1a and 1b The overall structure of a trickle dispenser according to a non-limiting embodiment of the present invention will be described. The trickle dispenser includes seven constituent elements, namely a fluid product reservoir 1 , a tube 2 , a flexible member 3 , a fixing ring 4 , a pressing piece 5 , a sleeve 6 and a cover 7 . The trickle dispenser can be divided into two subassemblies, a first subassembly consisting of the reservoir 1 and a second subassembly consisting of the constituent elements 2, 3, 4, 5, 6 and 7 and forming the dispensing head. The dispensing head is removably mounted on the reservoir by screwing / unscrewing. The tube 2 extends into the reservoir while being mounted on a flexible member 3 which engages a retaining ring 4 secured to the reservoir. The pressing piece 5 is movably mounted on the fixing ring 4 so as to deform the flexible member 3 . The sleeve 6 is engaged with the fixing ring 4, and the sleeve 6 cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com