Directional seeding device for super japonica rice seedling raising

A seed metering device and super japonica technology, applied in the field of agricultural machinery, can solve the problems of large one-time investment, irregular seed orientation, complex equipment structure, etc., and achieve the effects of novel and reasonable structure, low manufacturing cost and good operation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

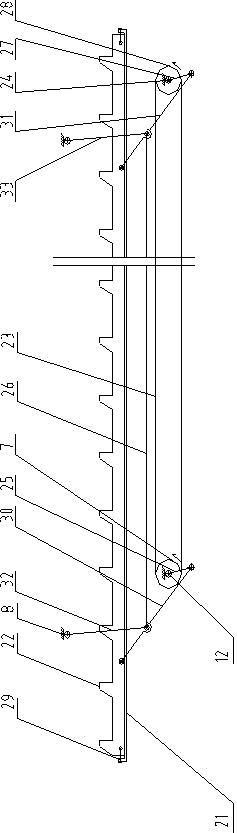

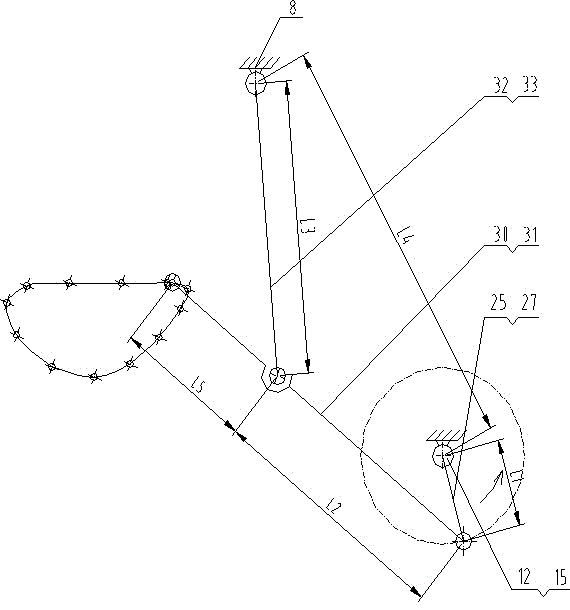

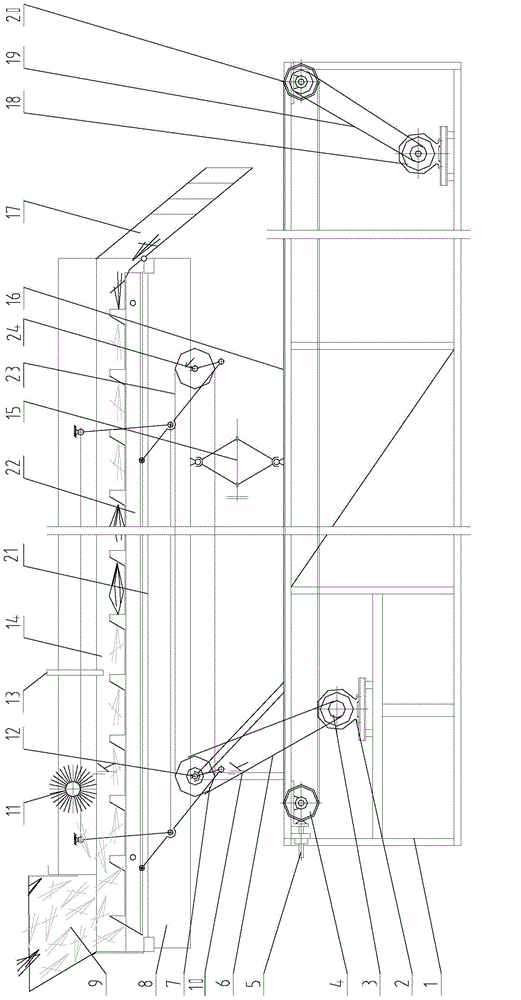

[0012] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. A super japonica rice seedling rearing directional seed metering device is equipped with a first speed regulating motor 2, a driven roller assembly 4, a second speed regulating motor 18, a driving roller on the left and right parts of the frame assembly 1, respectively. The assembly 20, the horizontal conveyor belt 16 is sleeved on the driven roller assembly 4 and the driving roller assembly 20, and the tensioning mechanism 5 connected to the frame assembly 1 is equipped on the driven roller assembly 4. The second transmission The chain 19 connects the second speed regulating motor 18 with the driving roller assembly 20; the fixing bracket 10 is installed on the upper end of the left side of the frame assembly 1, and the upper end of the fixing bracket 10 is rotatably fitted with the front drive shaft 12, two pieces The side plate 8 is hingedly mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com