Sprinkler turnplate driven by stepping motor and control method

The technology of a stepping motor and a sprinkler is applied in the directions of botanical equipment and methods, mechanical equipment, transmission devices, etc., which can solve the problems of time-consuming and laborious, inconvenient agricultural production, etc., and achieves good locking effect, convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

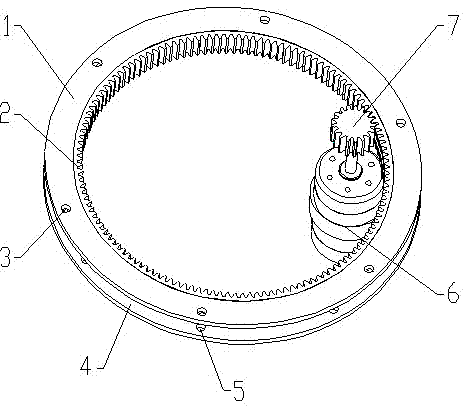

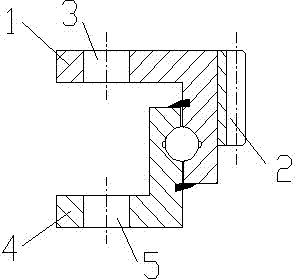

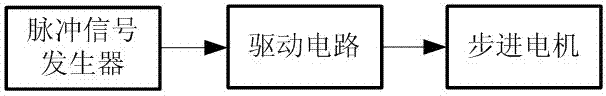

[0015] The turntable of the sprinkler irrigation machine driven by a stepping motor of the present invention is mainly composed of an inner disc 1, an outer disc 4, a gear 7, an inner ring gear 2, a pulse signal generator, a driving circuit, and a stepping motor 6. The upper end of the inner disk 1 has a flange, and the lower end of the outer disk 4 has a flange. The outer disk 4 is set on the inner disk 1. There are multiple balls that can move relative to each other between the inner disk 1 and the outer disk 4. The inner disk 1 and the outer disk 4 are set. A sealing ring is installed at the joint end; an inner gear ring 2 is fixed on the inner wall of the inner disc 1, and a gear 7 meshing with the inner gear ring 2 is arranged on the inner side of the inner disc 1, and the gear 7 is directly installed on the output of the stepping motor 6 on the shaft;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com